iGCL-HC(S)

iGOLDEN

iGOLDEN iGCL-HC(S)

| Availability: | |

|---|---|

Laser cleaning machines are an efficient and versatile solution for removing impurities from a variety of surfaces. They offer many advantages over traditional cleaning methods, including precision, speed, efficiency, and safety. With their ability to clean surfaces without harsh chemicals or abrasive materials, laser cleaners are also an environmentally friendly and cost-effective solution for businesses looking to maintain their equipment and facilities.

The laser cleaning process is a non-contact cleaning method that does not require any chemicals or abrasive materials, making it a safe and environmentally friendly option for surface cleaning. It is also an exact process that can remove the smallest particles or residues without damaging the surface or leaving any residue.

When selecting a laser cleaning machine, it is important to consider the specific needs of your application, such as the size and type of surface to be cleaned, the degree of contamination, and the precision required. If you are ready to buy a laser cleaning machine, you can contact us anytime. IGOLDENCNC is a professional manufacturer of laser cleaning machines, we can provide and customize laser cleaning machines for you according to your needs and will provide you with competitive prices.

Cleaning system | ||||

Content | Single axis | Dual axis | ||

Supply voltage | 1000W/1500W/2000W: Single-phase 220V±10%, 50/60Hz AC 3000W: Three-phase 380V±10%, 50/60Hz AC | |||

output method | Continuous light | |||

Power | ≤3000W | ≤2000W | ≤3000W | ≤3000W |

Language | Simplified, Traditional, English, Japanese, Korean, German and 13 other languages | Chinese, English, Russian, Japanese, Spanish, Korean, German, French | Simplified, Traditional, English, Japanese, Korean, German and 13 other languages | Chinese, English, customizable |

Operating mode | Linear mode | Line, Rectangle, Sine, Double Helix, Circle, Torus, Free Pattern | 6 kinds: horizontal line, vertical line, ellipse, etc | Straight line, helix, rectangle, circle, rectangle fill, circle fill |

Ranging function | None | The setting range is 0-1000mm | None | None |

Temperature measurement function | None | The measured temperature is the internal temperature of the cleaning head, the upper limit of the temperature can be set, and the default is 60°C | None | None |

Laser power adjustment | 10%-100% continuous gradient adjustable | |||

Laser frequency adjustment | 1kHz-30kHz continuous gradient adjustable (support customization) | |||

Focal length | 600mm | 400mm, 500mm: customized, cycle 2 weeks; 650mm: main push | 600mm | 800mm |

Cleaning head weight | 0.78kg | <1.2Kg | 0.96kg | 0.9KG |

Scan width | 0-300mm | 0-300mm | 0-200mm | 0-600/650mm |

Vibration lens material | Quartz | |||

Mirror material | Quartz | |||

Field lens material | Quartz | |||

Screen | Cabinet standard 7 inches | Cabinet standard 7 inches + cleaning head standard 2.8 inches | Cabinet standard 7 inches | Cabinet standard 7 inches |

Laser cleaning is a “green” cleaning method that does not need to use any chemicals or cleaning fluids. The cleaned waste is basically solid powder, small in size, easy to store, recyclable, and can easily solve the Environmental Pollution problems caused by chemical cleaning;

The traditional cleaning method is often contact cleaning. The surface of the object to be cleaned has mechanical force, and the surface of the object that will be damaged or the cleaning medium adheres to the surface of the object to be cleaned and cannot be removed, causing secondary pollution. The non-abrasive and non-contact laser cleaning solves these problems;

Laser cleaning can be transmitted through optical fiber, cooperate with robots to realize long-distance operation, and can clean parts that are difficult to reach by traditional methods;

Laser cleaning can remove all kinds of pollutants on the surface of various materials, and achieve cleanliness that cannot be achieved by conventional cleaning. In addition, it can selectively clean the contaminants on the surface of the material without damaging the surface of the material;

High efficiency of laser cleaning, saving time and effort;

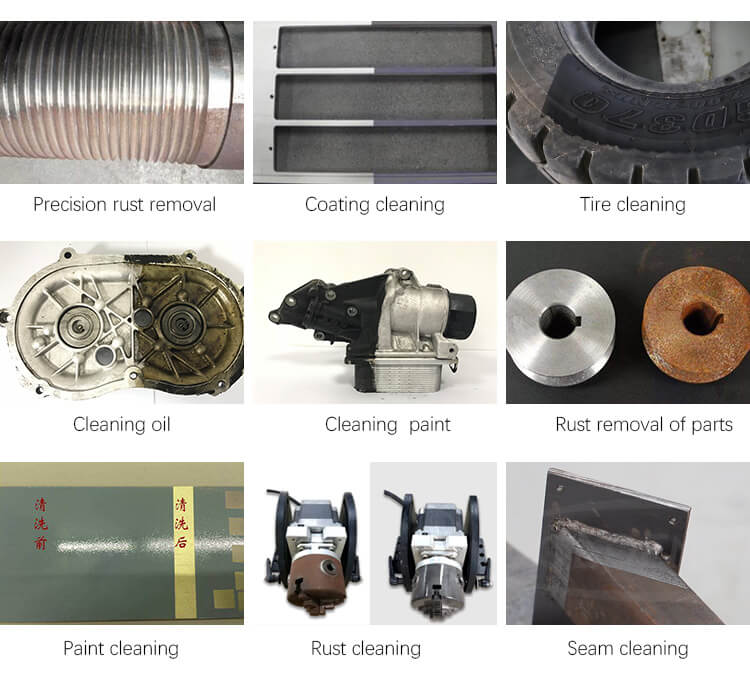

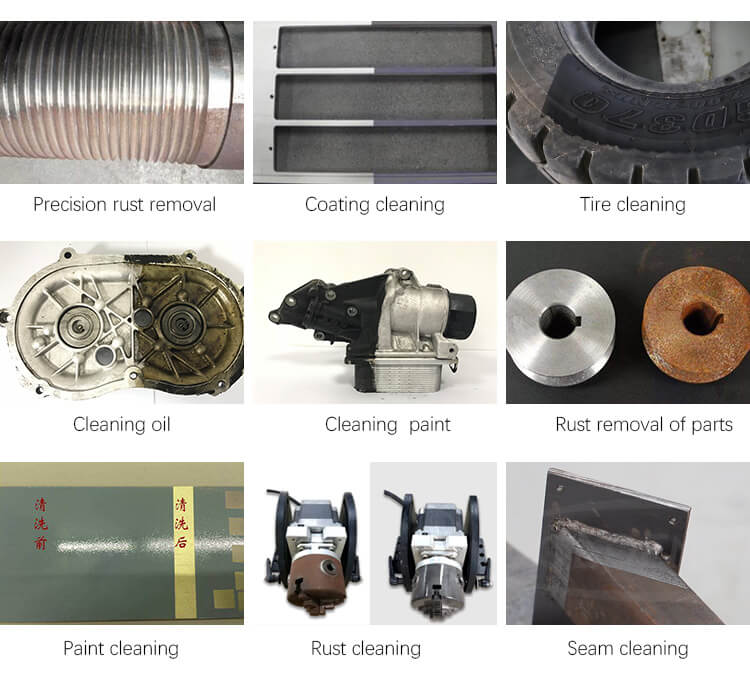

Metal surface rust removal

Paint cleaning

Oil stain, contaminant cleaning

Coating surface cleaning

Welding/Coating surface pre-treatment.

Stone figure surface dust & attachment cleaning.

Plastic Mold residues cleaning

Laser cleaning machines are an efficient and versatile solution for removing impurities from a variety of surfaces. They offer many advantages over traditional cleaning methods, including precision, speed, efficiency, and safety. With their ability to clean surfaces without harsh chemicals or abrasive materials, laser cleaners are also an environmentally friendly and cost-effective solution for businesses looking to maintain their equipment and facilities.

The laser cleaning process is a non-contact cleaning method that does not require any chemicals or abrasive materials, making it a safe and environmentally friendly option for surface cleaning. It is also an exact process that can remove the smallest particles or residues without damaging the surface or leaving any residue.

When selecting a laser cleaning machine, it is important to consider the specific needs of your application, such as the size and type of surface to be cleaned, the degree of contamination, and the precision required. If you are ready to buy a laser cleaning machine, you can contact us anytime. IGOLDENCNC is a professional manufacturer of laser cleaning machines, we can provide and customize laser cleaning machines for you according to your needs and will provide you with competitive prices.

Cleaning system | ||||

Content | Single axis | Dual axis | ||

Supply voltage | 1000W/1500W/2000W: Single-phase 220V±10%, 50/60Hz AC 3000W: Three-phase 380V±10%, 50/60Hz AC | |||

output method | Continuous light | |||

Power | ≤3000W | ≤2000W | ≤3000W | ≤3000W |

Language | Simplified, Traditional, English, Japanese, Korean, German and 13 other languages | Chinese, English, Russian, Japanese, Spanish, Korean, German, French | Simplified, Traditional, English, Japanese, Korean, German and 13 other languages | Chinese, English, customizable |

Operating mode | Linear mode | Line, Rectangle, Sine, Double Helix, Circle, Torus, Free Pattern | 6 kinds: horizontal line, vertical line, ellipse, etc | Straight line, helix, rectangle, circle, rectangle fill, circle fill |

Ranging function | None | The setting range is 0-1000mm | None | None |

Temperature measurement function | None | The measured temperature is the internal temperature of the cleaning head, the upper limit of the temperature can be set, and the default is 60°C | None | None |

Laser power adjustment | 10%-100% continuous gradient adjustable | |||

Laser frequency adjustment | 1kHz-30kHz continuous gradient adjustable (support customization) | |||

Focal length | 600mm | 400mm, 500mm: customized, cycle 2 weeks; 650mm: main push | 600mm | 800mm |

Cleaning head weight | 0.78kg | <1.2Kg | 0.96kg | 0.9KG |

Scan width | 0-300mm | 0-300mm | 0-200mm | 0-600/650mm |

Vibration lens material | Quartz | |||

Mirror material | Quartz | |||

Field lens material | Quartz | |||

Screen | Cabinet standard 7 inches | Cabinet standard 7 inches + cleaning head standard 2.8 inches | Cabinet standard 7 inches | Cabinet standard 7 inches |

Laser cleaning is a “green” cleaning method that does not need to use any chemicals or cleaning fluids. The cleaned waste is basically solid powder, small in size, easy to store, recyclable, and can easily solve the Environmental Pollution problems caused by chemical cleaning;

The traditional cleaning method is often contact cleaning. The surface of the object to be cleaned has mechanical force, and the surface of the object that will be damaged or the cleaning medium adheres to the surface of the object to be cleaned and cannot be removed, causing secondary pollution. The non-abrasive and non-contact laser cleaning solves these problems;

Laser cleaning can be transmitted through optical fiber, cooperate with robots to realize long-distance operation, and can clean parts that are difficult to reach by traditional methods;

Laser cleaning can remove all kinds of pollutants on the surface of various materials, and achieve cleanliness that cannot be achieved by conventional cleaning. In addition, it can selectively clean the contaminants on the surface of the material without damaging the surface of the material;

High efficiency of laser cleaning, saving time and effort;

Metal surface rust removal

Paint cleaning

Oil stain, contaminant cleaning

Coating surface cleaning

Welding/Coating surface pre-treatment.

Stone figure surface dust & attachment cleaning.

Plastic Mold residues cleaning