Views: 101 Author: igoldenCNC Publish Time: 2025-10-20 Origin: igoldenCNC

The world of manufacturing and fabrication has undergone significant changes in the past few decades, and at the forefront of this revolution is CNC laser cutting machines. These advanced machines have completely transformed how metal cutting is done, bringing unmatched precision, efficiency, and flexibility to the process. Whether you're in automotive, aerospace, electronics, or any other sector that requires metal fabrication, CNC laser cutting has become an indispensable technology.

In this blog, we'll explore how CNC laser cutting machines work, the benefits they offer over traditional methods, their applications, and why they're quickly becoming the go-to tool for metal cutting in modern industries.

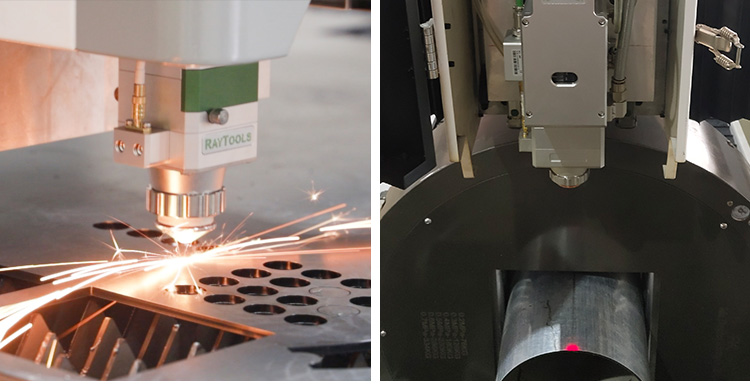

CNC laser cutting machines combine the power of lasers with computer numerical control (CNC) technology to cut, engrave, or etch materials with high precision. A laser beam is focused onto the metal surface, and the material is cut or engraved by melting, burning, or vaporizing it. The CNC system controls the movement of the laser, ensuring that the cuts are made according to a pre-programmed design, which is typically created using CAD (Computer-Aided Design) software.Plate and tube dual-purpose fiber laser cutting machine, can achieve two different profile cutting on the same machine tool, can cut metal sheet and pipe (square pipe, round pipe, channel steel, Angle steel, etc.). A multi-purpose machine, high cost performance, professional pipe cutting numerical control system, high precision, full function, easy to use, simple operation, suitable for comprehensive processing and manufacturing enterprises.

These machines are incredibly versatile and can be used to cut a wide range of materials, including stainless steel, aluminum, copper, brass, and various alloys. The laser cutting process can be applied to both thin and thick metals, making it ideal for industries that demand accuracy and flexibility.

| Model | iGR-FT 3015 | |

| Working area/ Tube length | 3000*1500mm/ 6000mm | |

| X axis stroke | 1500mm | |

| Y axis stroke | 3000mm | |

| Z axis stroke | 300mm | |

| Tube diameter | 20-220mm | |

| Accuracy | X, Y axis positioning accuracy | 0.05mm |

| X, Y axis repositioning accuracy | 0.03mm | |

| Speed | W axis rotate angle | n*360 |

| W axis max. ratate speed | 80rpm | |

| X, Y axis max. running speed | 150m/min | |

| U axis max. positioning speed | 800mm/s | |

| X, Y axis max. accelerated speed | 1.5G | |

| Power supply | Phase | 3 |

| Nominal voltage | 380V | |

| Frequency | 50/60Hz | |

| Protection grade | IP65 | |

| Machine body | Max. working loading | 1000kg |

| Body weight | 2600kg | |

| Size(L*W*H) | 8060*3000*1965mm | |

| Laser power | 500w/ 750w/ 1000w/ 1500w/ 2000w/ 3000w/ 4000w/ 5000w/ 6000w/ 8000w/ 10000w/ 12000w | |

| Worktable optional | 4000*1500mm/ 4000*2000mm/ 6000*2000mm/ 6000*2500mm | |

| Tube length optional | 3000mm/ 9000mm | |

At the core of CNC laser cutting is the interaction between the laser, the material, and the CNC system. Here’s a step-by-step breakdown of how it works:

The first step in the CNC laser cutting process is to create a digital design using CAD software. The design specifies the exact dimensions, shapes, and cuts required for the project. Once the design is finalized, it is converted into a file format that can be read by the CNC system, such as DXF or G-code.

Once the design file is ready, it’s loaded into the CNC system, and the metal workpiece is placed on the machine’s bed or cutting surface. The CNC system automatically sets the laser head in the correct starting position.

The laser cutting machine uses a focused laser beam to cut through the metal. The laser beam is generated by a high-power laser source, typically a CO2 laser or fiber laser. The laser is focused onto the material, and the heat generated by the laser causes the metal to melt, vaporize, or burn away, depending on the material and thickness.

As the CNC system moves the laser head along the programmed path, it cuts the metal with remarkable precision. In many cases, a gas (often oxygen or nitrogen) is used to assist the cutting process by blowing away the molten metal, which ensures a cleaner cut and prevents excess heat buildup.

After the cutting process is complete, the workpiece is removed from the machine and may undergo additional finishing steps, such as deburring or polishing, depending on the application.

One of the most significant advantages of CNC laser cutting machines is their high level of precision. The laser can make intricate cuts with minimal tolerance, typically as small as 0.1 mm. This precision is vital for industries where accuracy is paramount, such as aerospace, electronics, and automotive manufacturing. Unlike traditional mechanical cutting methods, which can suffer from wear and tear on blades and tools, lasers maintain their focus and sharpness, delivering consistently accurate cuts throughout the process.

Laser cutting is fast and efficient, particularly when dealing with high-volume production. The speed of the cutting process is one of the key advantages over other cutting methods. CNC laser cutting machines can cut through metals much faster than traditional methods like plasma cutting or mechanical saws, allowing manufacturers to increase productivity and reduce turnaround times.

Furthermore, CNC laser cutting machines can operate continuously with minimal downtime, further enhancing efficiency. Once the machine is set up and programmed, it can run without human intervention, leading to more streamlined workflows and lower labor costs.

Laser cutting is especially beneficial when it comes to creating complex shapes and designs that would be challenging or impossible to achieve with traditional cutting methods. The precision and flexibility of CNC laser cutting machines allow for the creation of intricate patterns, fine details, and custom shapes with ease. This capability makes laser cutting an ideal choice for industries requiring high levels of customization, such as signage, jewelry, or automotive parts.

Whether you need precise holes, slots, curves, or intricate engravings, CNC laser cutting can handle it all. The ability to create these shapes with high accuracy ensures that no additional finishing is needed, further enhancing the efficiency of the process.

One of the key advantages of CNC laser cutting is the reduction in material waste. Because the laser beam is extremely narrow, the kerf (the width of the cut) is minimal, meaning less material is removed during the cutting process. This not only saves on material costs but also contributes to a more environmentally friendly manufacturing process. The precise nature of the cuts allows manufacturers to maximize the use of their raw materials, which is especially important when working with expensive metals.

Unlike some other cutting technologies, CNC laser cutting machines can handle a wide range of material thicknesses. Depending on the power of the laser, it can cut through materials ranging from thin sheets of metal to thicker plates up to several inches in depth. Fiber lasers, for example, are particularly effective at cutting thicker metals, offering excellent cutting speeds and high-quality results.

The automatic lubrication system provides a fixed amount of lubricating oil for the equipment to ensure the high-speed operation of the flatbed laser cutter, with abnormal alarm and liquid level alarm functions. The system greatly improves the cutting accuracy and effectively extends the service life of the transmission mechanism.

Intelligent travel protection, automatic monitoring of the operating range of components, installation of international machine tool standard limit springs, the laser cutting head is built-in capacitor height adjustment function, collision stop, improve equipment and life safety protection, reduce the incidence of accidents, improve cutting efficiency.

Automatic alarm function for abnormal working status of equipment, and push it to the operation interface through the control center, improve the efficiency of flatbed laser cutting machine abnormal troubleshooting, reduce potential safety hazards, and reduce maintenance costs.

The automotive industry relies heavily on CNC laser cutting for producing high-precision components, such as body parts, chassis components, and exhaust systems. The ability to cut intricate designs with high precision ensures that parts fit together perfectly, contributing to the overall quality and performance of the vehicle. Laser cutting also plays a significant role in prototyping and custom parts fabrication, where speed and accuracy are crucial.

In aerospace, the tolerances for parts and components are extremely tight, making CNC laser cutting the preferred method for cutting metals used in aircraft. Laser cutting allows for the production of lightweight, precise, and intricate parts used in engines, wings, fuselage components, and other critical areas. The ability to cut complex shapes and thin-walled structures without compromising on strength is vital in aerospace manufacturing.

CNC laser cutting machines are also widely used in the electronics industry, particularly for cutting circuit boards and metal components. Lasers can cut extremely fine lines and shapes with precision, making them ideal for applications that require intricate patterns, such as circuit boards or connectors.

One of the most common uses of CNC laser cutting is in sheet metal fabrication. From custom metal parts to enclosures, brackets, and panels, laser cutting offers high precision and clean edges, which reduces the need for additional finishing steps. The ability to cut both thin and thick sheet metal with speed and accuracy has made laser cutting indispensable in the metal fabrication industry.

Laser cutting machines are increasingly being used to create custom signage, promotional displays, and artistic metal designs. The ability to cut and etch intricate patterns and shapes allows businesses to create custom designs that are visually striking and highly detailed. Artists and designers also use laser cutting for creating sculptures, custom art pieces, and other decorative elements.

When selecting a CNC laser cutting machine, there are several factors to consider:

Laser Type: The type of laser—whether CO2 or fiber—will affect the machine's cutting capabilities, speed, and suitability for different materials.

Power: Higher-powered lasers can cut through thicker materials and deliver faster cutting speeds, making them ideal for industrial applications.

Size and Capacity: The size of the machine's cutting bed and its ability to accommodate large workpieces are essential considerations based on your production needs.

Software Compatibility: Ensure that the CNC laser cutting machine is compatible with your existing CAD software for smooth integration into your production workflow.

Maintenance and Support: Consider the reliability of the machine and the manufacturer's customer support to ensure minimal downtime and efficient operation.

The advent of CNC laser cutting machines has dramatically altered the landscape of metal fabrication. Offering unmatched precision, speed, and flexibility, these machines enable manufacturers to produce complex metal parts with ease, all while minimizing material waste and maximizing efficiency.

As industries continue to demand more intricate designs, tighter tolerances, and faster production times, CNC laser cutting will remain an essential tool in achieving these goals. With continuous advancements in technology, the capabilities of laser cutting machines will only improve, making them even more indispensable in industries ranging from aerospace and automotive to electronics and custom fabrication.

If you’re looking to improve your metal cutting processes and take your fabrication capabilities to the next level, investing in a CNC laser cutting machine is the way to go. It’s a future-proof solution that will help streamline production, reduce costs, and provide the precision and quality your business needs to succeed.