1615S

iGOLDENCNC

iGK-1615S

| Availability: | |

|---|---|

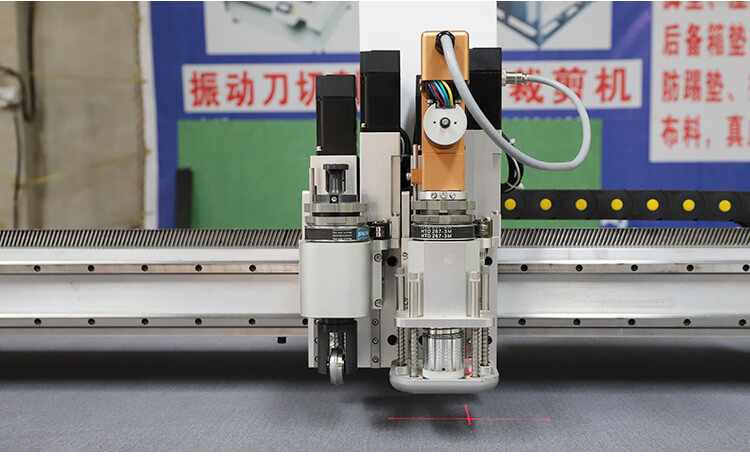

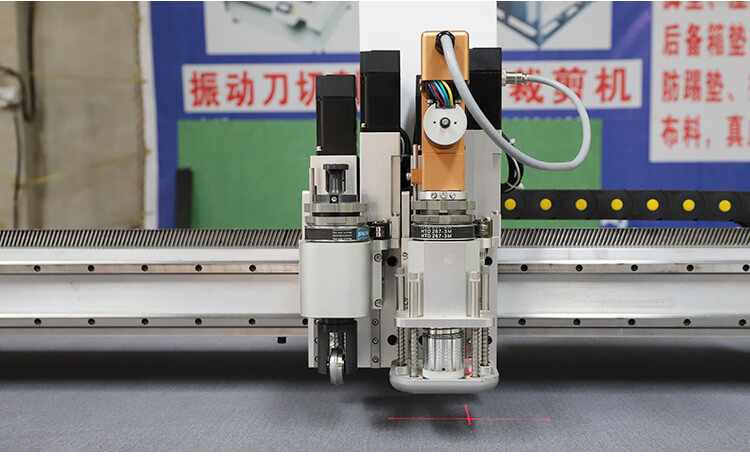

A CNC knife cutting machine is a professional automated digital cutting system that uses the up and down high-frequency vibration of the blade to cut flexible materials. It features with high precision, high speed, automatic loading and unloading, intelligent typesetting, and low cost of smooth incision processing. CNC digital knife cutters will take the place of the traditional manual flexible material cutting tools step by step. In the manufacture of automobile interiors, it is suitable for car mats, trunk mats, leather covers, seat covers, and cushions.

CNC vibration knife cutting machine is widely used in cutting paper materials, automotive interior processing industry, used in the cutting processing of car seat covers, seat cushions, steering wheel grips, leather processing industry, leather cutting and punching, household fabrics, cutting of new technology materials and other industries.

In the field of garment processing, it adopts high-power knife cutter and special fabric cutting blade with more flexible corners, which is used for high-end custom garment manufacturers. In addition, you can also add a knife cutter on a CNC router table to do precision cutting for flexible materials.

CNC Digital Knife Cutting Machine Parameter

CNC Digital Knife Cutting Machine ParameterTechnical indicators | parameter |

Model | iGK-1625(Size can be customized) |

Working Size | 2500(L)*1600mm(W) |

Dimensions | 3500*2200*1200mm(L*W*H) |

Machine body | Welded high strength integrated bed |

Platform | Aerospace aluminum vacuum adsorption platform |

Platform adsorption material | 4mm felt |

Tool | Vibrating knife |

Cutting speed | 200-2600mm/s |

Translatory velocity | 500-2800mm/s |

Cutting thickness | 0.1-40mm(The actual materials shall prevail) |

Cutting accuracy | 0.05mm(The actual materials shall prevail) |

Operating system | Zhongrui |

Vacuum pump | 9KW vacuum pump |

Drive part | Taiwan straight square rail and rack |

Miscellaneous function | Cross red light location |

Motor drive | Full servo motor drive |

Electric device | Chint/Omron |

Voltage | AC220V/380V,50Hz |

Optional tool | Round knife, punching knife, pneumatic knife, multi-layer knife, supporting knife, half cutter, oblique cutter, milling cutter, etc. |

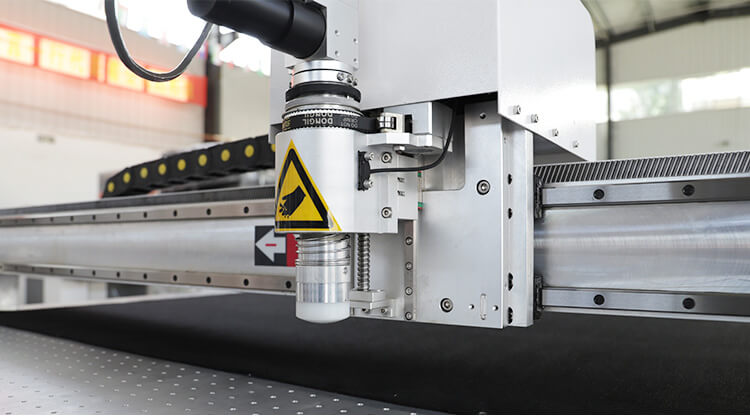

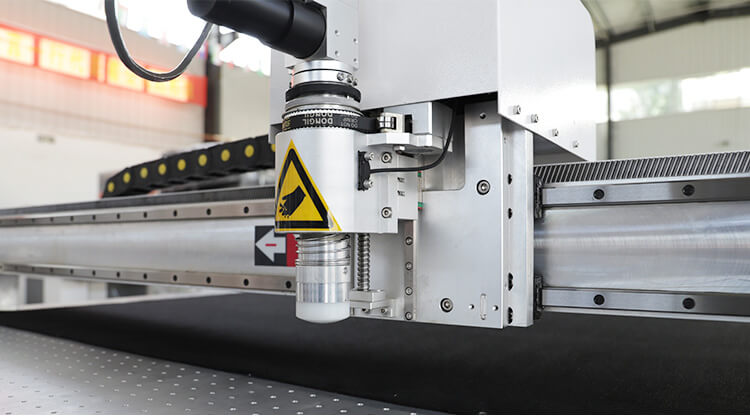

Automatic digital cutting machine (also known as CNC knife cutter) is a type of automated precision cutting system with CNC (Computer Number Controlled) controller which is used for high-precision cuts of heavier flexible and semi-rigid materials. It works with the multi-tool blades consisting of vibration knife, oblique knife, circular knife, punching knife, milling knife, punch roller, or marking pen. CCD camera and projector are optional for more precise cuts.

A automatic digital cutter is also known as digital cutting table, automatic flatbed cutter, cutting plotter, dieless cutter, flash cutter, CNC knife cutter, CNC drag knife, CNC tangential knife, CNC oscillating knife, automatic precision cutter, and CNC blade cutting table.

The finished product cut by the Oscillating knife cutting machine is very clean and neat, the edge is smooth, and the piece size is accurate, odorless, environmentally friendly.

Digital cutting technology replaces the traditional manual knife cutting process and helps business save a lot of cost and time on CNC knife manufacturing, management, and storage in the product development process.

Multifunctional CNC digital cutting head design and multiple sets of highly integrated processing tools, can be used as a work unit for interactive cutting, punching, and scribing.

A flatbed digital cutter can realize CNC cutting of difficult and complex patterns, template cutting that cannot be achieved by molds, greatly expands the design space, makes the template attractive, and makes the design truly achievable.

The discharge function is good, the calculation system automatically discharges, accurate calculation, cost calculation, accurate management of material release, and truly realizes the digital zero inventory strategy.

Through projector projection or camera shooting, master leather outline and effectively identify leather defects. In addition, according to the natural grain of the leather, the digital cutting direction can be adjusted at will to increase output, reduce wastage and improve the effective utilization of materials.

It can realize the timely modification of the model, save the development time, quickly put the board, and quickly change the board to adapt to the fast and changeable market demand.

Using self-developed CAM software, the system optimizes the physical overcutting phenomenon of the tool, greatly restores the graphic outline, and brings a satisfactory cutting effect to customers.

Intelligent table compensation function: The flatness of the table is detected by a high-precision range finder, and the plane is corrected in real time through the software to ensure high-quality cutting effects.

Combined with the table detection function, realize the intelligent front and back graphic sleeve cutting function. Multi-task and efficient cycle cutting, can be equipped with more suction.

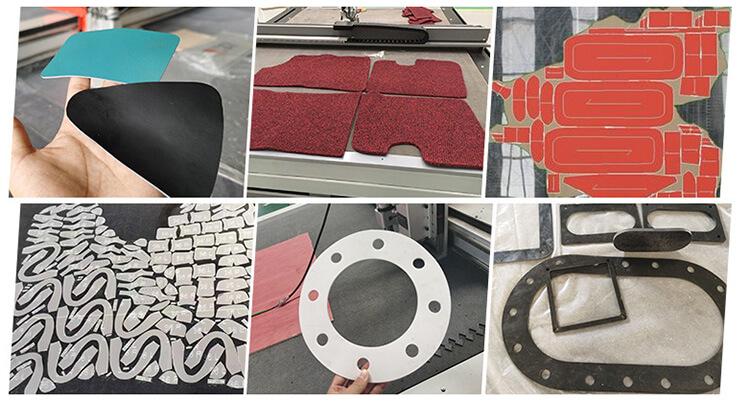

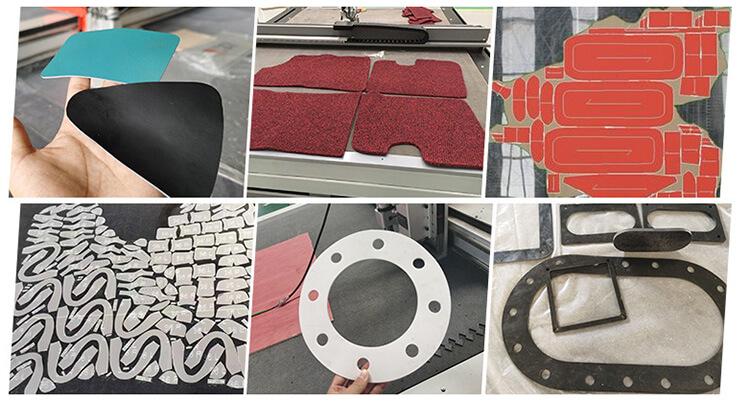

Vibration Cutting Machine Samples

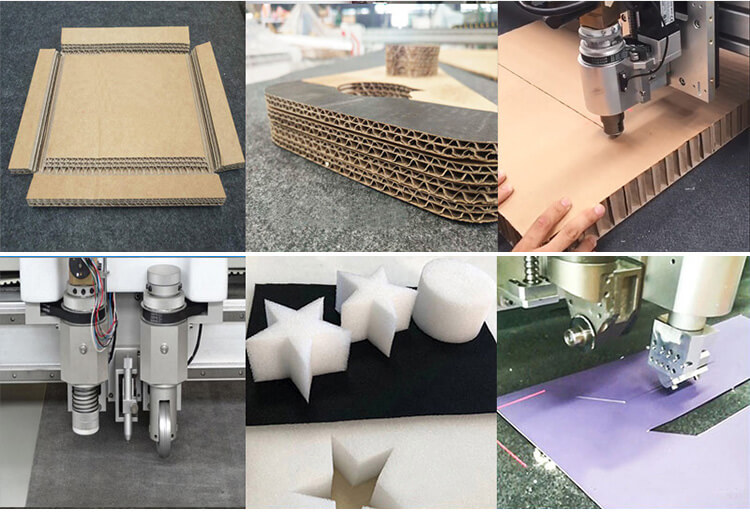

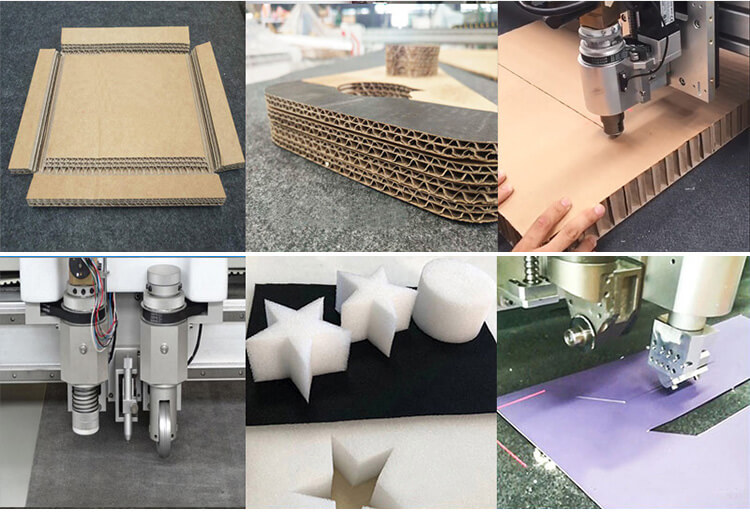

EVA foam, CUT CNC digital cutter machine can cut many types of foam, such as closed cell foam, rubber foam, foamex, foam core, KT board, EPE foam, polyethylene foam, PE foam, PVC foam, etc.It's widely used for packaging protection, advertising display, termal insulation, model & mock up making, puzzle and pattern cutting, etc.

Using cnc knife cutting technology, our digital cutter machine has no burning and totally environmently.It's equipped with plotting pen, oscillating cutting tool, creasing tool, and drag knife tool to meet customers' different requirements.The heavy duty drag knife tool is available for special materials of the sign making industry.

Cutting materials: kt board , foam board, honeycomb board, car mat, seat cover, corrugated, cardboard, kt board, gray board, composite materials, leather, corrugated box.

Cutting materials: Packing box, folding card, corrugated Board, carton,etc.

Cutting material: soft board , kt board , corrugated board, packing box, slotting of corrugated boxes, medium-density material v cuts, carton packaging, hard cardboard, gift boxes,etc.

Cutting materials: sticker, car sticker, reflective materials, self-adhesive vinyl, label, vinyl, engineering reflective film, double-layer adhesives, etc.

Cutting materials: asbestos board, asbestos free board, PTFE, rubber board , fluorine rubber board, silica gel board, graphite board, graphite composite board, etc.

Milling Knife Tool

Cutting materials: acrylic MDF board, pvc board, display stand, etc.

Cutting materials: backlit film, sticker, pp paper , folding card, flexible material less than 3mm thickness, advertising materials KT board, flexible plastics, mobile phone film, etc.

A CNC knife cutting machine is a professional automated digital cutting system that uses the up and down high-frequency vibration of the blade to cut flexible materials. It features with high precision, high speed, automatic loading and unloading, intelligent typesetting, and low cost of smooth incision processing. CNC digital knife cutters will take the place of the traditional manual flexible material cutting tools step by step. In the manufacture of automobile interiors, it is suitable for car mats, trunk mats, leather covers, seat covers, and cushions.

CNC vibration knife cutting machine is widely used in cutting paper materials, automotive interior processing industry, used in the cutting processing of car seat covers, seat cushions, steering wheel grips, leather processing industry, leather cutting and punching, household fabrics, cutting of new technology materials and other industries.

In the field of garment processing, it adopts high-power knife cutter and special fabric cutting blade with more flexible corners, which is used for high-end custom garment manufacturers. In addition, you can also add a knife cutter on a CNC router table to do precision cutting for flexible materials.

CNC Digital Knife Cutting Machine Parameter

CNC Digital Knife Cutting Machine ParameterTechnical indicators | parameter |

Model | iGK-1625(Size can be customized) |

Working Size | 2500(L)*1600mm(W) |

Dimensions | 3500*2200*1200mm(L*W*H) |

Machine body | Welded high strength integrated bed |

Platform | Aerospace aluminum vacuum adsorption platform |

Platform adsorption material | 4mm felt |

Tool | Vibrating knife |

Cutting speed | 200-2600mm/s |

Translatory velocity | 500-2800mm/s |

Cutting thickness | 0.1-40mm(The actual materials shall prevail) |

Cutting accuracy | 0.05mm(The actual materials shall prevail) |

Operating system | Zhongrui |

Vacuum pump | 9KW vacuum pump |

Drive part | Taiwan straight square rail and rack |

Miscellaneous function | Cross red light location |

Motor drive | Full servo motor drive |

Electric device | Chint/Omron |

Voltage | AC220V/380V,50Hz |

Optional tool | Round knife, punching knife, pneumatic knife, multi-layer knife, supporting knife, half cutter, oblique cutter, milling cutter, etc. |

Automatic digital cutting machine (also known as CNC knife cutter) is a type of automated precision cutting system with CNC (Computer Number Controlled) controller which is used for high-precision cuts of heavier flexible and semi-rigid materials. It works with the multi-tool blades consisting of vibration knife, oblique knife, circular knife, punching knife, milling knife, punch roller, or marking pen. CCD camera and projector are optional for more precise cuts.

A automatic digital cutter is also known as digital cutting table, automatic flatbed cutter, cutting plotter, dieless cutter, flash cutter, CNC knife cutter, CNC drag knife, CNC tangential knife, CNC oscillating knife, automatic precision cutter, and CNC blade cutting table.

The finished product cut by the Oscillating knife cutting machine is very clean and neat, the edge is smooth, and the piece size is accurate, odorless, environmentally friendly.

Digital cutting technology replaces the traditional manual knife cutting process and helps business save a lot of cost and time on CNC knife manufacturing, management, and storage in the product development process.

Multifunctional CNC digital cutting head design and multiple sets of highly integrated processing tools, can be used as a work unit for interactive cutting, punching, and scribing.

A flatbed digital cutter can realize CNC cutting of difficult and complex patterns, template cutting that cannot be achieved by molds, greatly expands the design space, makes the template attractive, and makes the design truly achievable.

The discharge function is good, the calculation system automatically discharges, accurate calculation, cost calculation, accurate management of material release, and truly realizes the digital zero inventory strategy.

Through projector projection or camera shooting, master leather outline and effectively identify leather defects. In addition, according to the natural grain of the leather, the digital cutting direction can be adjusted at will to increase output, reduce wastage and improve the effective utilization of materials.

It can realize the timely modification of the model, save the development time, quickly put the board, and quickly change the board to adapt to the fast and changeable market demand.

Using self-developed CAM software, the system optimizes the physical overcutting phenomenon of the tool, greatly restores the graphic outline, and brings a satisfactory cutting effect to customers.

Intelligent table compensation function: The flatness of the table is detected by a high-precision range finder, and the plane is corrected in real time through the software to ensure high-quality cutting effects.

Combined with the table detection function, realize the intelligent front and back graphic sleeve cutting function. Multi-task and efficient cycle cutting, can be equipped with more suction.

Vibration Cutting Machine Samples

EVA foam, CUT CNC digital cutter machine can cut many types of foam, such as closed cell foam, rubber foam, foamex, foam core, KT board, EPE foam, polyethylene foam, PE foam, PVC foam, etc.It's widely used for packaging protection, advertising display, termal insulation, model & mock up making, puzzle and pattern cutting, etc.

Using cnc knife cutting technology, our digital cutter machine has no burning and totally environmently.It's equipped with plotting pen, oscillating cutting tool, creasing tool, and drag knife tool to meet customers' different requirements.The heavy duty drag knife tool is available for special materials of the sign making industry.

Cutting materials: kt board , foam board, honeycomb board, car mat, seat cover, corrugated, cardboard, kt board, gray board, composite materials, leather, corrugated box.

Cutting materials: Packing box, folding card, corrugated Board, carton,etc.

Cutting material: soft board , kt board , corrugated board, packing box, slotting of corrugated boxes, medium-density material v cuts, carton packaging, hard cardboard, gift boxes,etc.

Cutting materials: sticker, car sticker, reflective materials, self-adhesive vinyl, label, vinyl, engineering reflective film, double-layer adhesives, etc.

Cutting materials: asbestos board, asbestos free board, PTFE, rubber board , fluorine rubber board, silica gel board, graphite board, graphite composite board, etc.

Milling Knife Tool

Cutting materials: acrylic MDF board, pvc board, display stand, etc.

Cutting materials: backlit film, sticker, pp paper , folding card, flexible material less than 3mm thickness, advertising materials KT board, flexible plastics, mobile phone film, etc.