Views: 18 Author: Site Editor Publish Time: 2022-07-22 Origin: Site

CNC router atc is an high power CNC machine center with affordable price. It's ideal for aiming to automate their production processes.

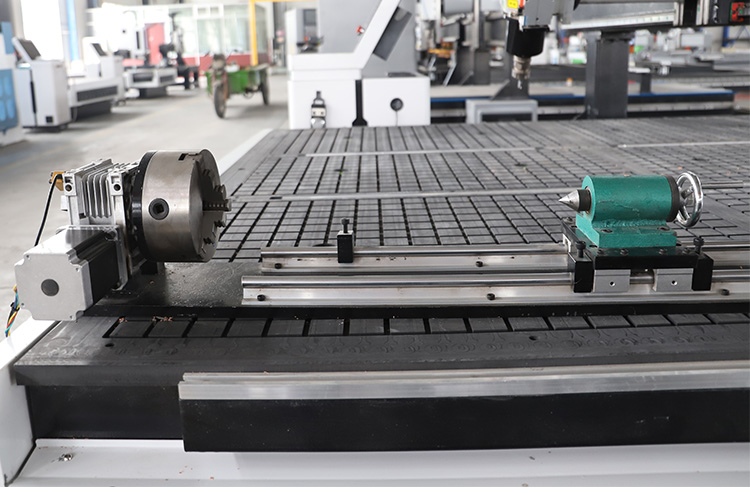

1) The whole machine adopts seamless welding of steel structure, with strong bearing capacity and small deformation. Linear square rail, high precision, wear-resistance and stable operation.

2) Adopt a linear fixed or follow-type automatic tool change system, the tool change time only needs ten seconds, which saves tool change time and improves production efficiency.

3) Professional factory with Mach 3 control system, can provide good after-sales service and technology support

4) File preprocessing function helps users correct errors in processing files in time and is well compatible with processing codes generated by Type3/Artcam/Aspire/Solidworks etc. In the three-dimensional curve prediction algorithm, the broken line is stable, to ensure the speed and accuracy of the curve.

5) Dust collection and adsorption device: The dust collection system can absorb wood chips and debris during the processing process, and maintain the equipment in disguised form to keep the workbench clean; the multi-zone vacuum adsorption table can be used for adsorption of different sizes of plates instead of The mechanical plate fixing in the past has shortened the loading and unloading time of the plate outside of processing.

6) It has the function of breakpoint and continuous engraving after a power failure, and automatic error correction function when returning to the origin, which effectively guarantees the processing accuracy when working for a long time.

Cnc Router Atc Application:

And it is suitable to deep-processing cutting off, grooving, carving and milling of all non-metallic material and soft materials with the most economical and reasonable method.

1. Carpentry decoration Industry.

2. Home Decoration Industry: relief carving and cutting of fresco, screen etc.

3. Wooden artware industry: processing different kinds of wooden arts and crafts.

4. Furniture Industry: 2D, 3D relief carving and cutting of door, bed, computer desk, chairs etc.

5. Advertising industry: giant acrylic cutting, chest card making, stereo advertising board making etc.

6. Door Industry: single line and relief carving and cutting of cabinet door, solid wood door, security door etc.

7. Instrument Industry: linear and relief carving and cutting of various wooden or acrylic instruments, like guitar, violin, guitar etc.

How to maintenance cnc router atc

1,Computer

Regular killing the virus, but can not open the antivirus degree of attention to work carefully interference.

Regular cleaning of the dust of the chassis, and attention to the cooling of the chassis, carefully excessive dust caused by industrial control card error.

Regularly defragment the hard disk, optimize the computer system.

Computer abnormalities can also cause many problems, especially for connecting CNC router, we summarize our technical department maintenance found in the process of wood engraving machine, computer anomalies also give us repair caused a lot of unnecessary trouble, but also delay the customer's business, , asked the client computer maintenance attention to several aspects.

2,the clean-up

Regular cleaning of industrial control box, the biggest killer of dust on the circuit board.

Regular cleaning of the screw to prevent the screw on the stick of a foreign body, screw device is very important, he determines the accuracy of the machine, and the screw also play an important role in the transmission process.

Work is done timely clean countertops, which provides a convenient next to wood CNC router.

Cleanup rail and the rail next to the material crumbs, to prevent the card machine cause the machine in the work process from debris interference.

3,oil

After the addition of oil, slow back and forth to ensure that the lubricant can be uniformly applied to the rail and screw.

Machine unused for long periods should periodically refuel empty go to ensure the flexibility of the transmission system.

First, clean up clean rail with screw, available in cloth (do not shed) clean out the oil on the rails and lead screw and material debris. Low temperatures, rail and screw add oil and antifreeze oil is best.

The refueling cycle twice a month, that is, every two weeks and once oil.

4,the temperature

Machine when not in use, if the room temperature is lower best pour the water in the tank to prevent the cracking of water tanks and water pipes.

The ambient temperature in the operating room, wood engraving machine is best to reach room temperature, at least the staff will not be cold.

View the fuel standard applicable temperature to reach at least the minimum temperature.

Temperature for atc cnc router machine is not very big, but because of the user to screw with butter, winter also forgot to clean-up, resulting in each boot failed to get off, and some studio temperature is too low, add the oil, can or frozen on the machine is not running.

5,cooling water

Conditional antifreeze cooling.

Pay attention to environmental temperature, be careful because the water temperature is too cold, the water tank and the pipe cracking.