Views: 45 Author: Site Editor Publish Time: 2022-06-02 Origin: Site

CNC slate engraving industry after decades of development, applied more widely , with the recent advances in technology , digital technology becomes more perfect, especially in the high-end CNC technology has made great breakthroughs .

1. For the acrylic cutting of the stone engraving machine, we recommend the use of a single-edged spiral milling cutter, which is characterized by being smokeless, odorless, fast, efficient, non-sticky, and truly environmentally friendly. Its special manufacturing process ensures the processing of acrylic. No cracking, very fine blade (even without blade), smooth and flat surface. The machined surface needs to achieve a matte effect, and it is recommended to use double-edged and triple-edged helical milling cutters.

2.engraving machine for granite stone MDF cutting (for advertising mold opening), it is recommended to use a double-edged large-chip spiral milling cutter. It features two high-capacity flutes and a double-edged design. It achieves good tool balance. It has no blackness, is smoke free and has a long service life when dealing with medium and high density boards.

3. For aluminum cutting with engraving machine for granite stone, single-edged aluminum milling cutters are recommended. Non-sticky during processing, fast and efficient.

4. The top and bottom of the stone engraving machine are cut without burrs. It is recommended to use single-edged, double-edged up and down milling cutters.

5. It is recommended to use stone engraving machine for metal engraving processing, it is recommended to use single-edged, double-edged, straight-grooved flat-bottomed sharp knife.

6. 3D engraving knife for stone engraving machine with high concentricity and sharp edge for precise 3D engraving.

7. Thecnc marble engraving machine adopts high density board, and it is recommended to use a solid wood milling cutter.

8. It is recommended to use stone engraving machine for multi-layer board, plywood processing, double-edged straight groove milling cutter.

9. The stone engraving machine is used for precision small relief processing, and a round bottom knife is recommended.

10. Stone carving machine for cork, medium density fiberboard, log, PVC, acrylic large-scale deep relief processing, recommended single-blade spiral ball mill.

11. The effect of using the tool under the stone engraving machine, there is no burr on the upper surface of the processed product, and it will not warp during processing.

12. For the metal mold processing milling cutter of the stone engraving machine, it is recommended to use a tungsten steel milling cutter. Finished in violet black and hard titanium.

13. A diamond engraving knife is recommended for acrylic engraving on a stone engraving machine.

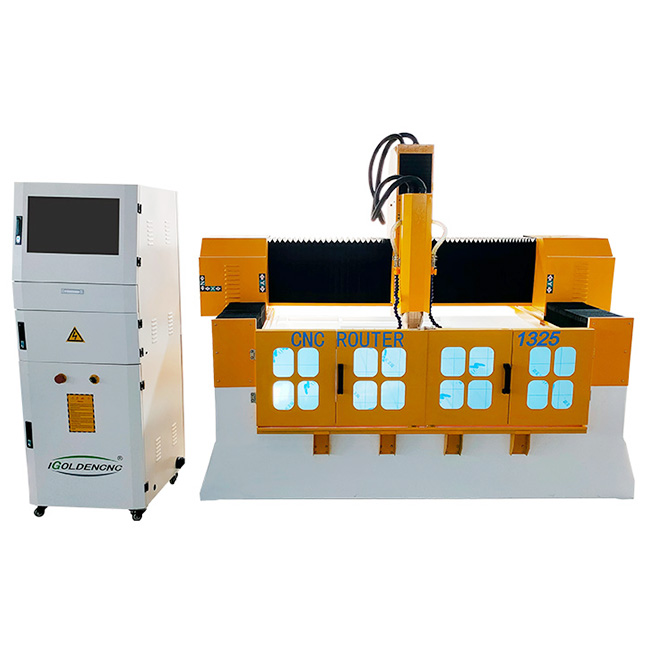

CNC Stone Engraving Machine Features:

1).Entry-level type CNC stone engraving machine characterized of versatility, low cost and easy operation, suitable for small biz, home hobbyist & start-up entrepreneur.

2).Strong machine structure welded by thick square tubes, which goes through strict vibration aging technology to remove internal stress and dust-free sandblasting paint process, long-term use without deformation.

3).Rack pinion transmission for X/Y axis, fast working and high efficiency; high precision ball screw for Z axis with high precision and long life time.

4).Top-rated motors & drivers to keep the running more stable and can improve the processing precision.

5).High-speed water cooling spindle which can work perfectly for stone cutting and carving.

6).Dedicated & user-friendly software, eg. Type 3, Artcam, Castmate, Wentai, etc., which have excellent compatibility with CAD/CAM software.

7).Independently electric control box with perfect wiring and free moving pulleys.

Stone cnc router / stone engraving machine is specially designed for engraving / carving / cutting stone or similar material. Optional water tank and automatic water cooling system make stone processing works easier and more convenient.

The working efficiency of this stone cnc router is twice higher than the one with single head because it has two heads, which can work together and do the same job. This will save a lot of time and labor.