Views: 10 Author: Site Editor Publish Time: 2022-02-17 Origin: Site

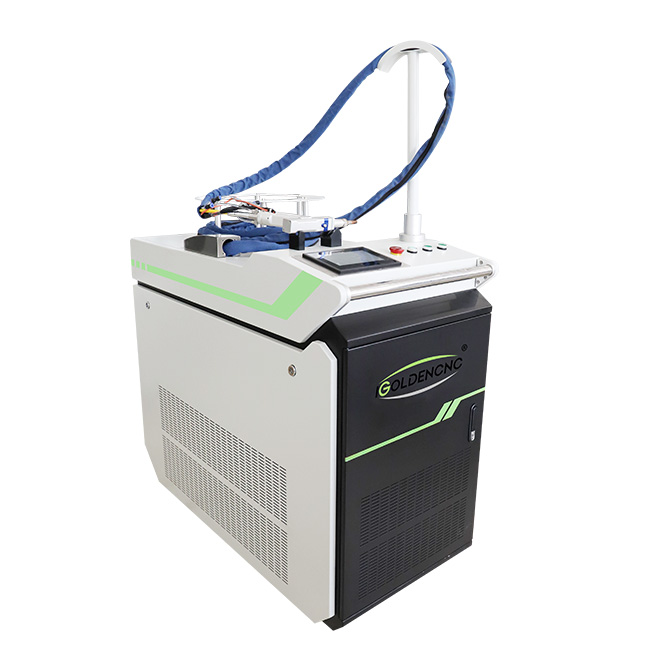

The cnc welding machine uses a hand-held swing welding head, which is flexible and simple to

operate without the need for professional welder technology, Suitable for small batch and large batch production. Widely used in sheet metal processing, kitchen cabinets, cabinets, stair handrails, elevator escalators, display shelves, doors and windows, advertising models, stainless steel products and many other industries.

It is important to be familiar with the operation and general maintenance of hand-held laser welding before starting to work with these machines. Experts recommend performing a general review of the operation so that all its components work as they should. However, if unusual problems occur, it is essential not to manipulate electrical components or the laser and notify the technical service to solve any incident that is not indicated how to solve it in the instruction manual.

There are some basic maintenance steps that we can carry out on our laser machine, thus we will extend the life of the machine components, consumables and save costs. Some users wonder what kind of maintenance these laser equipment have, and the truth is that it is not complicated at all and they are equipment with few consumables , always depending on the type of work we do and the care we take. Some of the most common actions to take to keep the laser welding machine in good condition are the following:

Replace lens protector.The lens protector is placed in a small drawer on the laser gun, it is very easy to replace. The lens protector can be damaged if we do not use the gas correctly when welding or if it gets dirty.

Replace the focus lens.It is essential to carry out this action in a dust-free environment. This lens is placed in a gas block on the gun itself.

The laser and gas outlet tube must always be clean inside. To check its good condition, the equipment must be turned off and remove the tube by unscrewing it to remove it from the gun.

The nozzles are easily replaced by turning them counterclockwise. It is important to keep them clean and use them properly.

The laser cooler must be controlled periodically, checking the water level and cleanliness. In case this is not as it should be, change the water in the refrigerator properly with deionized distilled water.

The laser gun must be clean.

Periodic inspections of the lens protector , make sure it is free of marks, contamination or dirt.

Advantages of cnc welding machine:

Laser welding can be thin-walled materials, precision parts to achieve spot welding, butt welding, stack welding, sealing and so on.

Laser power, the weld has a high aspect ratio, heat affected area is small, small deformation, welding speed.

Weld quality high flat appearance, no pores, after welding material toughness at least equivalent to the parent material.

Humanized design, LCD display, centralized button operation is more simple.

Four-dimensional ball screw table, the use of imported servo control system, optional rotary table, you can achieve spot welding, linear welding, circumferential welding and other automatic welding, for a wide range of high precision and fast.

The current waveform can be adjusted arbitrarily according to the different welding wave, so that the welding parameters and welding requirements to match, in order to achieve the best welding results.