Views: 17 Author: Site Editor Publish Time: 2021-12-06 Origin: Site

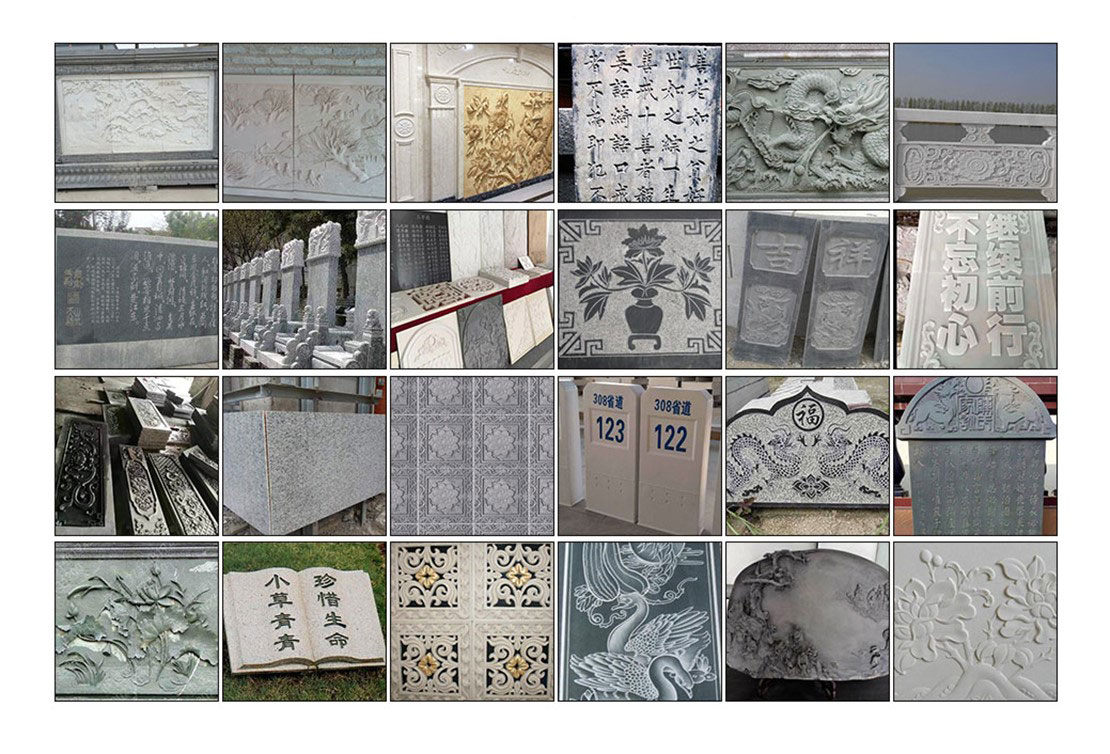

Engraving machine for granite stone is suitable for natural marble, granite, blue-stone, sandstone, artificial stone, tombstone, milestone.etc,The machine is with two 5.5KW constant power, t slot table with water tank for water recycling, dust proof for protection of linear guide rail. This machine mainly for stone relief carving, tombstone carving and other stone processing.

Special R&D for stone processing, heavy-duty structure, strict vibration aging treatment, effective removal of welding residual stress, the lather can work ten years without deformation

Special electric braking technology, ensure the machine head will not drop down even power failure suddenly, effectively protect the head, tools and the workpiece.

High-precision liner guide rail, with high-speed rack gear transmission, to ensure long-term stable running

Restoring engraving function enable the machine continue working after sudden stop

Dustproof and oil lubrcations structure, to ensure the long-term operation of mechanical transmission system

Special high-power frequency changing spindle, water cooling ype, specialized in various stone processing, such as, marble, granite, jade, nature and artificial stone etc.

High compatibility with CAD/CAM software such as type3, ArtCam, AutoCAD, Ucancam, Jdpaint etc.

How to correctly operating engraving machine for granite stone or common steps?

A:1)Before the stone engraving machine boot, first determine all machine connected to the computer normal, and then open the machine and computer power supply. after completed the system starts to enter the numerical control system.

2)Calibration coordinates system for engraving machine. open control system after select "back to the mechanical origin" menu. The machine will automatically return to the mechanical origin (In some cases, the user does not have to perform mechanical reduction operations).

3)loading program for the need carving style, otherwise, some related to the automatic processing function is invalid.

4)Determine the origin of the workpiece, the X, Y two directions of cnc granite engraving machine manual walked to the origin of hope on the workpiece position, starting with the current point to stone engraving.

Inspiration for cnc stone engraving machine price

The surface of the stone is melted during laser engraving. Here, the material is processed directly. That is why no template has to be created for this application. Furthermore, the laser beam is the universal tool for all shapes and material thicknesses. Unlike milling cutters, no separate tool head is required for different materials, shapes or material thicknesses, saving time and money in the production process.

Function and advantages of laser technology

Incredible design opportunities

Productive processing

One tool for all shapes

Simple high-quality manufacturing

Applicable IndustryMainly suitable for building stone industry, tombstones processing industry, arts embossment industry, advertising, decoration, ceramics industry etc.

Applied Materials3D/2D engraving, Embossment, Line engraving Cutting, Edge inversing, Drilling on Natural stones, Granites, Artifical stones, Tombstones, Milestones, Ceramic

Stone, tombstone processing, advertising, decoration, wood furniture, handicraft industries. It can be for murals, marble, granite, tombstone, milestones, tile and other stone carvings for text and graphics engraving and relief. glass, wooden fish stone and other hard materials engraving and cutting.

Scope of Application