iGS-D

iGOLDEN

iGOLDEN-iGS-D

| Availability: | |

|---|---|

This stone engraving cnc router machine with solid gantry and lathe bed,stable lathe table,fast speed and high accuracy.

Imported ball screw ensures stable movement and high accuracy.

Water cooling spindle and high performance subdivision driver ensure to work stably for long time.

With water tank and double water cooling system,high efficient works.

With practical software,can check the moving path of tool,and adjust theprocessing depth of Z axis and the speed of motor.

Technical Data

| X, Y Axis Working Area | mm | 1300*2500 |

| Z Axis Working Height | mm | 500 |

| Positioning Accuracy | mm | 0.05 |

| Re-positioning Accuracy | mm | 0.02 |

| Body Structure | Welding Body | |

| X, Y Axis Structure | Linear Guide Rail, Gear Rack | |

| Z Axis Structure | Linear Guide Rail, Screw | |

| Max. Running Speed | mm/min | 20000 |

| Max. Working Speed | mm/min | 8000 |

| Spindle | kw | 4.5kw Water-cooling Spindle*2(Optioned) |

| Spindle RPM | rpm/min | 24000 |

| Working Voltage | V/Hz | AC 380V±10%/50-60Hz |

| Machine Weight | kg | 1500/1900 |

| *Some specifications can be customized upon request, please contact us | ||

Configuration

| Spindle | HQD Water-cooling Spindle (Italy HSD Spindle Optioned) | Machine Body | Heavy-duty Split-type Welding Body, Fixed with Screw |

| Worktable | Complex Worktable (Aluminum Profile+PVC+S.S. Sink) | Control System | DSP/ NCSTUDIO(Taiwan SYNTEC System Optioned) |

| Ball Screw | Taiwan TBI | Guide Rails | Taiwan HIWIN |

| Gear Rack | Taiwan T-WIN | Reducer | Japan SHIMPO |

| Electric Components | France SCHNEIDER | Frequency Converter | Taiwan DELTA |

| Driver | LEADSHINE Stepper Motor(Japan YASKAWA Servo Motor optioned) | Lubrication System | Automatic Lubrication Device (Optioned) |

| Optioned | Rotary Device, Automatic Tool Sensor, Swing Head, Covered Door, Automatic Leveling | ||

Size

Machine Configuration

HQD 4.5kw water cooling spindle

HIWIN guide rails | TBI ball screw

LEADSHINE Step Drive and Stepper Motor | Japan SHIMPO reducer

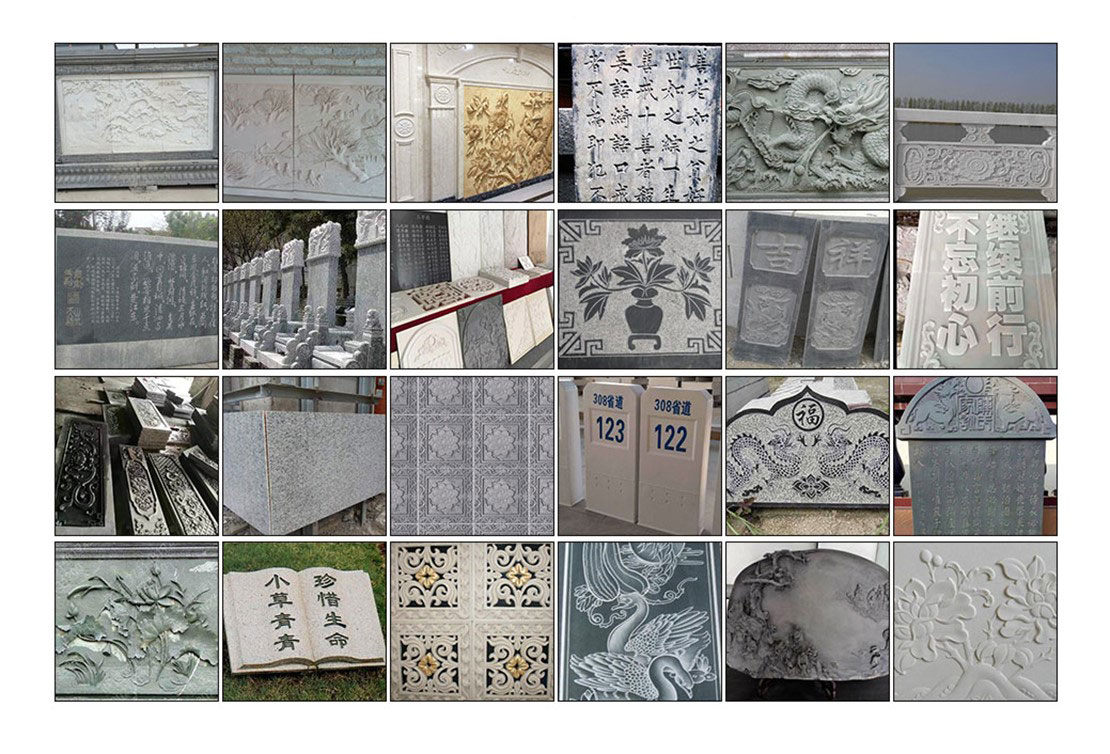

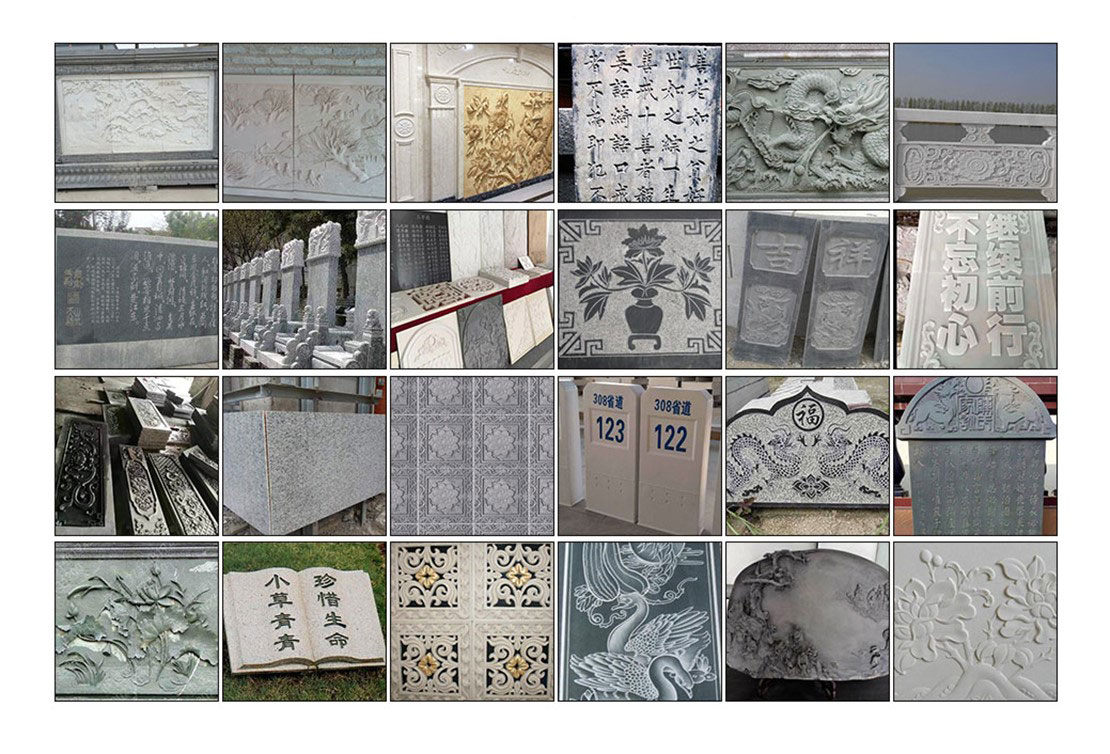

Scope of Application

Stone industry: stone, artificial stone cutting, tombstone, jade and marble products;

Stone stele industry: tombstones, monuments, merit steles, stele caps, tile eaves, etc .;

Kitchenware industry: artificial marble cabinet desktop;

Art decoration industry: wooden crafts, gift boxes, jewelry boxes and other exquisite crafts;

Woodworking industry: chairs, doors, windows, beds, cupboards, kitchenware and other furniture; mahogany classical and antique furniture, exquisite European furniture, sculpture decoration products;

Mold industry: carved copper, aluminum and other metal molds; architectural models, shoes, badges, embossing molds, cookies, candy, chocolate molds; artificial marble, plastic cloth, pvc, wood, foam and other non-metal molds.

iGOLDENCNC Factory View

Customer Visiting

iGOLDENCNC Service

| Pre-sales |

| > Free pre-sale consultation |

| > Free sample testing |

| > Professional CNC solutions |

| > Customer reception |

| > Fast delivery within 7 days(Available in stock) |

| > Customized machines delivered within 30 days |

| After-sales |

| > 2-year warranty |

| > Fast feedback and after-sales service in 12 hours |

| > Fast spare parts and technical assistance |

| > Free training services |

| > Special design, customized, OEM order |

FAQ:

1.What material does the stone carving machine process?

Most of stone materials, such as natural stone, marble, artificial stone, granite, sandstone, bluestone, terrazzo, and other materials, such as glass, ceramic tile, wood, aluminum plate, copper plate.

2.Which industry does the stone processing machine used for?

Stone background wall, bridge engineering, garden engineering, tombstone engineering and other industries.

3.What kind of work is the stone engraving machine suitable for?

The main function is plane carving, relief, line carving, cutting, lettering, hollowing, chamfering, drilling, etc..

This stone engraving cnc router machine with solid gantry and lathe bed,stable lathe table,fast speed and high accuracy.

Imported ball screw ensures stable movement and high accuracy.

Water cooling spindle and high performance subdivision driver ensure to work stably for long time.

With water tank and double water cooling system,high efficient works.

With practical software,can check the moving path of tool,and adjust theprocessing depth of Z axis and the speed of motor.

Technical Data

| X, Y Axis Working Area | mm | 1300*2500 |

| Z Axis Working Height | mm | 500 |

| Positioning Accuracy | mm | 0.05 |

| Re-positioning Accuracy | mm | 0.02 |

| Body Structure | Welding Body | |

| X, Y Axis Structure | Linear Guide Rail, Gear Rack | |

| Z Axis Structure | Linear Guide Rail, Screw | |

| Max. Running Speed | mm/min | 20000 |

| Max. Working Speed | mm/min | 8000 |

| Spindle | kw | 4.5kw Water-cooling Spindle*2(Optioned) |

| Spindle RPM | rpm/min | 24000 |

| Working Voltage | V/Hz | AC 380V±10%/50-60Hz |

| Machine Weight | kg | 1500/1900 |

| *Some specifications can be customized upon request, please contact us | ||

Configuration

| Spindle | HQD Water-cooling Spindle (Italy HSD Spindle Optioned) | Machine Body | Heavy-duty Split-type Welding Body, Fixed with Screw |

| Worktable | Complex Worktable (Aluminum Profile+PVC+S.S. Sink) | Control System | DSP/ NCSTUDIO(Taiwan SYNTEC System Optioned) |

| Ball Screw | Taiwan TBI | Guide Rails | Taiwan HIWIN |

| Gear Rack | Taiwan T-WIN | Reducer | Japan SHIMPO |

| Electric Components | France SCHNEIDER | Frequency Converter | Taiwan DELTA |

| Driver | LEADSHINE Stepper Motor(Japan YASKAWA Servo Motor optioned) | Lubrication System | Automatic Lubrication Device (Optioned) |

| Optioned | Rotary Device, Automatic Tool Sensor, Swing Head, Covered Door, Automatic Leveling | ||

Size

Machine Configuration

HQD 4.5kw water cooling spindle

HIWIN guide rails | TBI ball screw

LEADSHINE Step Drive and Stepper Motor | Japan SHIMPO reducer

Scope of Application

Stone industry: stone, artificial stone cutting, tombstone, jade and marble products;

Stone stele industry: tombstones, monuments, merit steles, stele caps, tile eaves, etc .;

Kitchenware industry: artificial marble cabinet desktop;

Art decoration industry: wooden crafts, gift boxes, jewelry boxes and other exquisite crafts;

Woodworking industry: chairs, doors, windows, beds, cupboards, kitchenware and other furniture; mahogany classical and antique furniture, exquisite European furniture, sculpture decoration products;

Mold industry: carved copper, aluminum and other metal molds; architectural models, shoes, badges, embossing molds, cookies, candy, chocolate molds; artificial marble, plastic cloth, pvc, wood, foam and other non-metal molds.

iGOLDENCNC Factory View

Customer Visiting

iGOLDENCNC Service

| Pre-sales |

| > Free pre-sale consultation |

| > Free sample testing |

| > Professional CNC solutions |

| > Customer reception |

| > Fast delivery within 7 days(Available in stock) |

| > Customized machines delivered within 30 days |

| After-sales |

| > 2-year warranty |

| > Fast feedback and after-sales service in 12 hours |

| > Fast spare parts and technical assistance |

| > Free training services |

| > Special design, customized, OEM order |

FAQ:

1.What material does the stone carving machine process?

Most of stone materials, such as natural stone, marble, artificial stone, granite, sandstone, bluestone, terrazzo, and other materials, such as glass, ceramic tile, wood, aluminum plate, copper plate.

2.Which industry does the stone processing machine used for?

Stone background wall, bridge engineering, garden engineering, tombstone engineering and other industries.

3.What kind of work is the stone engraving machine suitable for?

The main function is plane carving, relief, line carving, cutting, lettering, hollowing, chamfering, drilling, etc..

content is empty!