Views: 20 Author: igoldenCNC Publish Time: 2024-12-13 Origin: igoldenCNC

The foam CNC machine is a specialized tool that has become a crucial part of various industries, including manufacturing, art, and design. Whether you're creating foam prototypes, sculptures, or custom foam parts for packaging, a foam CNC machine provides the precision and versatility needed for high-quality results.

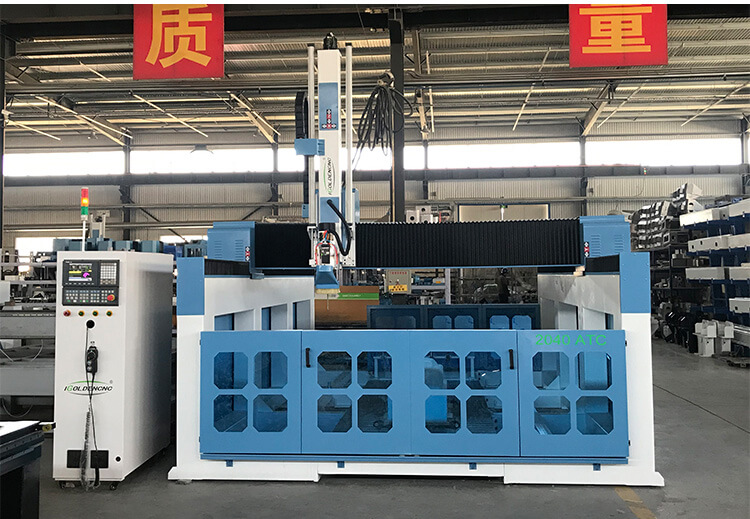

4 axis CNC Wood Carving Machine is one kind of foam CNC machines, it is mainly working as a CNC foam cutter for styrofoam carving, it has a big working dimension, does a good job in carving or cutting of large scale workpieces in different materials, such as wood, aluminum, styrofoam.

Foam CNC machine is a computer-controlled cutting tool designed specifically for shaping and cutting foam materials. This machine operates similarly to other CNC machines, using software to control its movements along the X, Y, and Z axes, along with rotational capabilities depending on the machine's configuration.

The machine can cut various foam types, including but not limited to:

Polyurethane foam

EPS (Expanded Polystyrene) foam

XPS (Extruded Polystyrene) foam

PE (Polyethylene) foam

EVA (Ethylene Vinyl Acetate) foam

The cutting process is carried out with utmost precision, allowing the foam to be shaped into any custom design, including 2D and 3D shapes, making it suitable for a wide variety of applications.Foam CNC machine automate the cutting process, significantly reducing production time compared to manual cutting methods. They can cut multiple foam pieces simultaneously, improving efficiency and productivity in model making and prototyping workflows.

In addition to cutting foam, some foam CNC cutting machines can be equipped with additional tools for performing tasks such as engraving, drilling, and chamfering. This versatility allows for a wider range of applications and enables users to create more complex and multi-functional foam models.

A foam CNC machine uses computer-aided design (CAD) software to create detailed designs and paths for the cutting tool to follow. Here’s how the process works step by step:

Design: The user creates a design in CAD software. This could be a simple shape or a complex 3D model, depending on the project.

Programming: The design is then translated into a set of instructions that the CNC machine can follow. The machine operator uses CAM (Computer-Aided Manufacturing) software to create a toolpath based on the design.

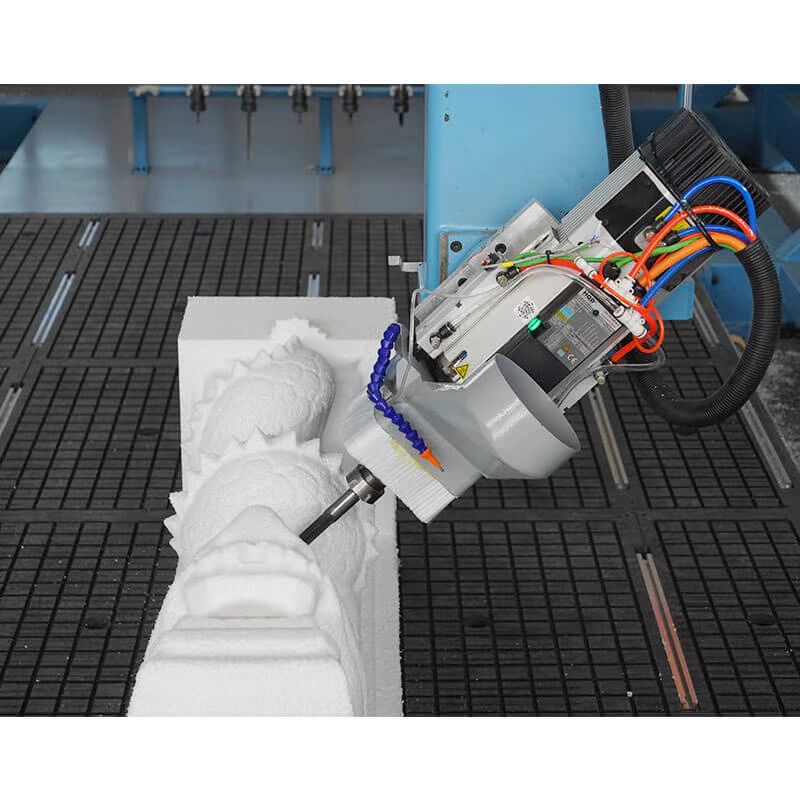

Cutting: Once the design is uploaded to the CNC foam cutter, the machine uses its cutting tool (often a rotating blade or router bit) to follow the programmed path. The foam is cut layer by layer to create the desired shape.

Finishing: After the cutting is done, the foam may require some finishing touches, such as sanding or smoothing edges, depending on the level of detail required for the project.

The flexibility and precision of foam CNC machines make them ideal for creating complex geometries, fine details, and clean cuts that would be difficult or impossible to achieve with manual methods. By using CAD software and converting designs into machine-readable instructions, users can quickly and accurately produce foam models based on their specific requirements. This enables designers and engineers to iterate and refine their designs before moving to full-scale production.

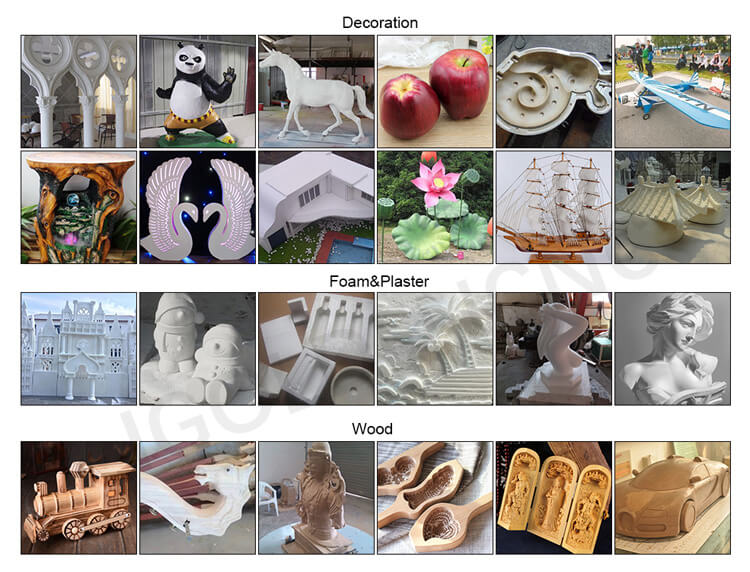

Foam CNC machines are used in a wide range of industries. Below are some of the most common applications:

In industries such as automotive, aerospace, and product design, foam CNC machines are often used for creating prototypes. Foam is lightweight, easy to cut, and cost-effective, making it a perfect material for prototype models. Designers and engineers use CNC foam cutting machines to create functional prototypes that help visualize designs before production.

Foam is frequently used in packaging, especially for delicate or fragile items. CNC foam machines are used to create custom foam inserts for packaging, ensuring that products remain secure during transit. With the precision of a CNC machine, businesses can create perfectly fitted foam cushions that prevent damage to valuable items.

Foam CNC machines are widely used to create signage and display items. Whether it’s for trade shows, retail signage, or architectural displays, foam can be easily shaped into logos, letters, or 3D shapes for eye-catching visual displays. The machines can cut intricate details that would otherwise be too complex for traditional methods.

Artists have embraced the versatility of foam CNC machines to create detailed sculptures and models. Foam’s ease of carving and shaping, coupled with the CNC machine’s precision, allows artists to create everything from abstract sculptures to life-sized models with intricate details. Foam sculptures are often used for exhibitions, installations, and even film sets.

In furniture design, foam CNC machines are used to shape foam for cushions, seats, and backrests. The machines can create custom foam shapes that fit perfectly into furniture designs, allowing for high comfort and aesthetic appeal. Additionally, CNC foam cutting machines are used to cut foam for prototype furniture pieces.

The automotive and aerospace industries use foam CNC machines to create lightweight parts for vehicles and aircraft. The foam components are used for insulation, cushioning, and soundproofing. In aerospace, foam is often used for making models of aircraft parts for testing and development purposes.

Foam CNC machines are also used in architectural applications, such as creating foam models for building designs or mockups. Foam can be easily shaped into detailed building components, such as columns, arches, and decorative elements. It's also used to create molds for concrete pouring or other construction materials.

One of the key advantages of using a CNC foam cutter is its precision. The computer-controlled cutting ensures that every part is created to exact specifications. Whether you need straight cuts, curves, or intricate designs, the machine will follow the programmed instructions with impeccable accuracy.

CNC foam machines allow for complete customization. Whether you need a unique shape, specific size, or intricate detailing, CNC technology makes it possible to create virtually any foam design. The machine can cut 2D and 3D shapes with ease, offering endless possibilities for custom projects.

Foam CNC machines work much faster than manual methods, increasing productivity. The automation provided by CNC technology allows for continuous operation without the need for constant manual intervention, speeding up production times and reducing human error.

Although the initial investment in a CNC foam machine can be significant, it pays off in the long run due to its efficiency, precision, and minimal waste. Foam is relatively inexpensive compared to other materials, and CNC machines maximize material usage by cutting with extreme accuracy, reducing wastage.

Once a design is programmed into the CNC system, it can be repeated indefinitely with the same precision. This consistency is particularly valuable when producing large quantities of identical parts, ensuring that every piece meets the same high-quality standards.

Foam CNC machines are capable of handling both simple and complex designs. The versatility of these machines makes them suitable for a wide range of industries, from artistic sculpting to industrial applications.

Hand-tool working greatly affects the efficiency and quality of mold making. CNC have the advantages of uniform margin, fast processing speed, and high processing quality, this CNC router is widely used in many industries, which not only improves the quality of mold castings but also shortens the mold production cycle.

The CNC foam cutter machine has revolutionized the way industries approach foam cutting and shaping. With unparalleled precision, speed, and customization options, these machines are transforming everything from artistic sculptures to industrial parts production. The versatility of CNC foam cutters makes them invaluable tools for a wide range of applications, including prototyping, signage, packaging, and furniture design.

As technology continues to advance, the potential for what can be achieved with CNC foam cutting will only grow. Whether you're a designer, manufacturer, or artist, investing in a CNC foam machine is a step toward unlocking new creative possibilities and improving production efficiency.