Views: 51 Author: Site Editor Publish Time: 2021-12-22 Origin: Site

IGOLDENCNC handheld laser welder cost adopts the latest generation of fiber laser and is equipped with an intelligent laser welding head. It has many advantages such as simple operation, beautiful welding line, fast welding speed and no consumables. Welding applications in metal materials such as thin stainless steel plates, carbon steel plates, and galvanized sheets can perfectly replace traditional argon arc welding and electric welding. laser welding machine can be widely used in kitchen cabinets, stair elevators, shelves, ovens, stainless steel door and window guardrails, distribution boxes, stainless steel home and other industries.

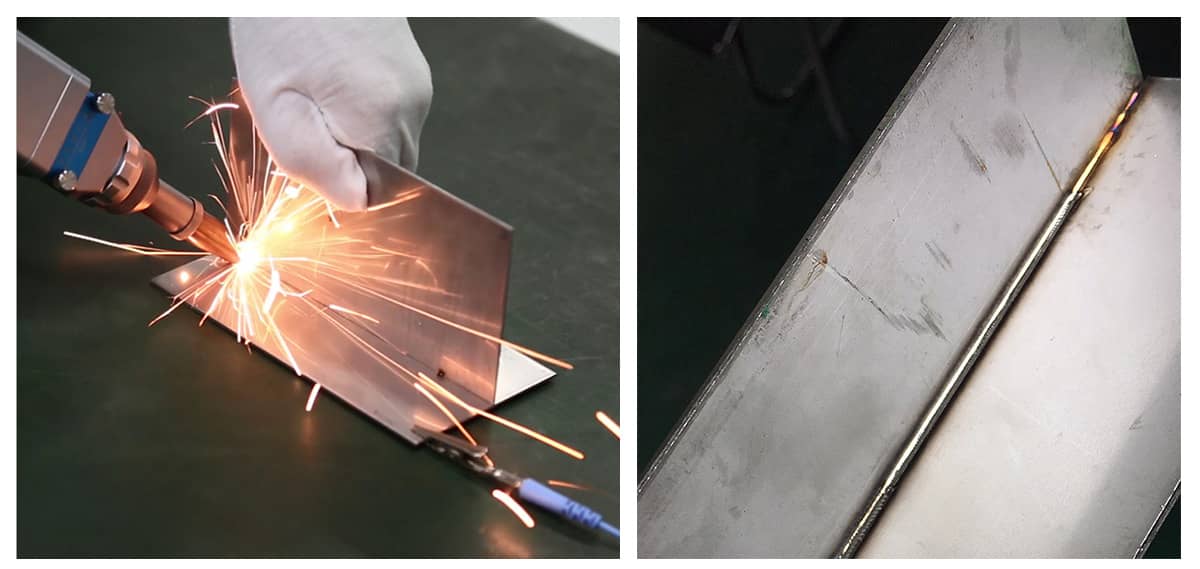

High quality result: Small, beautiful and smooth weld seam, no pores, high weld depth ratio and high welding quality, the toughness after welding is comparable to that of the parent material.

High powered machine: large laser power, high efficiency, no consumables, long-term processing is possible;

Flexible: Spot welding, butt welding and precision welding can be realized for thin-walled materials and precision parts;

Versatile: Can be used for special-shaped welding, splicing welding and spot welding, large laser power is sufficient to weld metals that is not easily to be melted such as gold, silver and copper. It can weld small and delicate geometric areas.

IGOLDENCNC handheld laser welding machine adopts hand-held welding head, which has the characteristics of no consumables, small size, flexible processing, and low operation and maintenance cost. If you need to know more, you can communicate online.

The handheld laser welding machine can perform long-distance laser welding of largeworkpieces. The heat affected area is small during welding, and it will not cause deformation, blackening, and traces on the back of the workpiece.

The connection depth is large, the welding is firm, and the melting is sufficient.

There is no depression in the joint between the raised part of the molten material in the bath and the substrate!

The welding speed is fast, 2-10 times faster than traditional welding, and one machine can save at least 2 welders a year.

The advantage of laser welding wobble head

1. The process that the conventional head can not complete, the dithering head only needs to use about

70% of the power, so that the cost of the laser can be saved;

2 Wobble welding back and forth through the galvanometer motor, so that the bubbles with large impurities

can reduce bubbles, frying, splashing, etc.

3 In the case of irregular gaps, the requirements for the fixture can be reduced.

The conventional oscillating head welding gap is generally 0.2 mm, and light exceeding this width directly

passes through. The width of the gap that can be welded by the oscillating head can reach 0.5mm,

but the conventional welding head can only be welded to 0.2mm. There is no galvanometer motor in

the welding head, so there is no swing. The welding effect is not good, the welding process is limited.