Views: 24 Author: Site Editor Publish Time: 2021-09-30 Origin: Site

IGOLDENCNC offers a complete range of laser welding solutions. Laser weldingis a non-contact process, which requires access to the weld zone from only one side of the parts being welded. The laser weld is formed as the intense laser light rapidly heats the material - typically calculated in milliseconds. As Handheld laser welding machine is a non-contact process, a great number of joint geometries can be welded. Laser welders can join a wide range of steels, nickel alloys, titanium, aluminium, and copper. They are ideal for applications where the components would deform under mechanical pressure.

Our Handheld laser welding machine systems provide very high production volumes at a low cost per weld and very accurate part positioning, even after welding. Laser Welders also provide extremely high-quality seam-welds for sealing critical electronics packages, such as those used for pacemakers. The most significant requirement is that there must be a close fit at the joint interfaces.

The special feature of the Penwelder BLT is its flexibility and versatility in its application. Whether our customers weld laser stitches, weld entire seams or only set isolated welding points, the contact tips developed for the specific application always give you a qualitatively reproducible result.

Handheld laser welding machine Working with standard welding heads are designed to focus a collimated laser beam to a required spot size, keeping the beam path static through the beam delivery and a static spot at the focal plane. This standard configuration limits each setup to a specific application.

Laser Welding Machine Working with Wobble welding heads incorporate scanning mirror technology inside a standard weld head. By oscillating the beam with internal mirrors, the focal spot is no longer static, and can be dynamically adjusted by changing the shape, amplitude, and frequency.

●Welds smooth, beautiful, no need to deal with after welding or just a simple process.

●Focus spot diameter is small, to protect the welding power density and processing range.

●Low maintenance costs, reduced power consumption and routine maintenance costs.

●Weld quality, no pores, can reduce and optimize the base metal impurities, the organization can be refined after welding , weld strength, toughness at least equivalent to even more than the parent metal.

●Can be precise control, focusing light small, high-precision positioning, easy to ac hi eve automation. Can achieve some of the dissimilar materials between the welding.

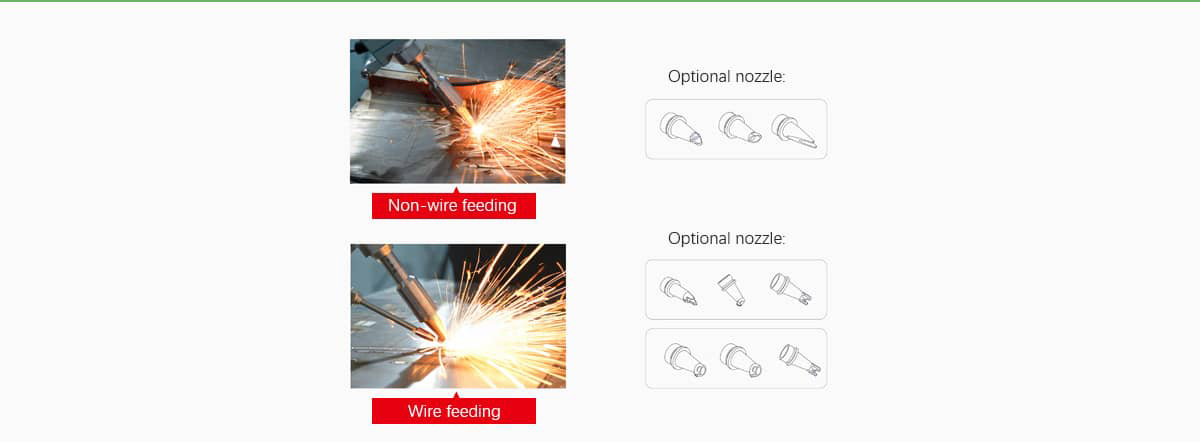

standard welding head

wobble welding head

Wobble welding (or oscillation welding) is where a high-beam-quality laser is used with a galvo scan-head to rapidly oscillate the focal spot.

Wobbling effectively increases beam diameter during laser welding, increasing the width of the weld while maintaining the efficiency of deep keyhole welding. This method of welding enables much easier control of weld parameters such as weld width and depth of penetration which can lead to a more efficient welding process.

Compared to common laser welding, wobble laser welding best for wider seam welding and deep penetration welding.

Fiber laser technology with wobble, increases the quality and productivity of high-power fiber laser welding.

This method of welding enables much easier control of weld parameters such as weld width and depth of penetration which can lead to a more efficient welding process.

The switching is simple and practical.

Laser Welding Machine Working Application

Widely used in the IT industry, medical equipment, machinery manufacturing, elevator manufacturing, craft gifts, household appliances manufacturing,automobile shipbuilding and other industries.

Application Materials

Laser Welding Machine Working can be used in welding stainless steel, aluminum, copper, chromium, nickel, titanium and other metals or alloys.