Views: 62 Author: igoldenCNC Publish Time: 2023-06-30 Origin: igoldencnc

The cost of a laser welder can vary widely depending on the manufacturer, model, and features. Entry-level laser welders can start at around $5,000, while industrial-grade models can cost tens of thousands of dollars.

Power output: Laser welders with higher power output will typically be more expensive.

Brand: Well-known brands with a reputation for quality may have higher prices.

Features: Laser welders with additional features such as automatic gas control, CNC compatibility, and digital displays will typically be more expensive.

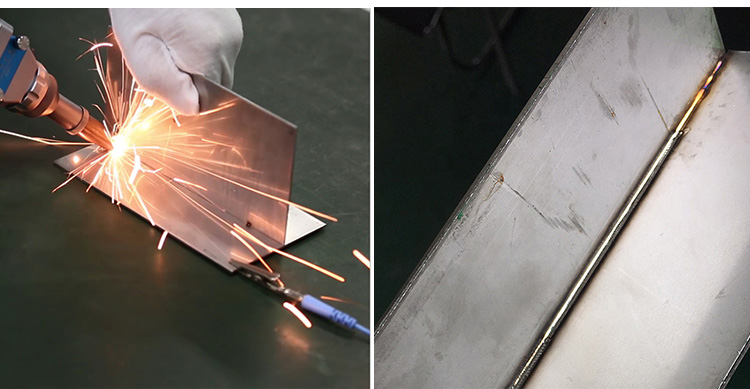

Laser welding is a welding technique that uses a laser beam to join materials together. It is a non-contact welding process that generates a highly concentrated beam of light, typically from a laser source, to create a localized heat zone at the welding point.

The laser beam used in laser welding is focused on the workpiece, and the intense heat generated by the laser rapidly melts and fuses the materials being joined. The laser beam can be precisely controlled, allowing for precise and accurate welding.

Precision and Accuracy: Laser welding allows for precise control of the welding process, resulting in accurate and consistent welds. It is particularly suitable for joining small or delicate parts and for applications that require high precision.

Speed and Efficiency: Laser welding is a fast process due to the concentrated heat source and high energy density of the laser beam. It can complete welds quickly, increasing productivity and efficiency.

Minimal Distortion: Laser welding produces minimal distortion and heat-affected zones compared to other welding techniques, as the heat input is localized to the welding area. This is beneficial for applications where distortion needs to be minimized.

Versatility: Laser welding can be used to join a wide range of materials, including metals and alloys, as well as dissimilar materials. It is applicable to various industries, such as automotive, aerospace, electronics, and medical device manufacturing.

Laser welding is commonly used for applications that require high precision, cleanliness, and quality welds. It is particularly useful in industries where fine weld seams and intricate weld geometries are required.