Views: 14 Author: Site Editor Publish Time: 2021-12-02 Origin: Site

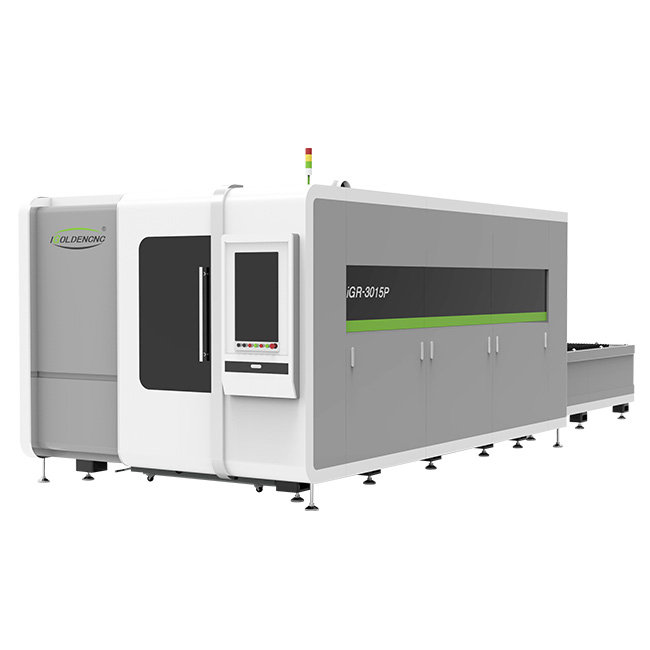

Laser metal cutting machine excels cutting works with invincible cutting speed for various metals like carbon steel, stainless steel, aluminum, brass, copper, titanium, and other non-ferrous metals. Its full enclosed 120" x 60" cutting area provides the highest level of working environment. The equipped IPG laser source features a constantly stable laser beam, high efficiency and maintenance-free operation.

Because a brand new full-automatic laser metal cutting machine is made up of many components combined with each other, in order to ensure the quality of the fiber laser cutter, it is necessary to inspect the components.

1.Laser Machine

As one of the core parts of the fiber laser machine, the role of the laser is to provide a “power source” for the entire device. Without a laser, the automatic laser tube cutting machine cannot work normally. At the same time, the quality of the laser also directly reflects the quality of the automatic laser tube cutting machine.

2. Laser lens

The quality of the laser lens can directly affect the output power of the laser of the automatic laser tube cutting machine. Different types of laser lenses have different functions. The laser lens is not only the core part of the laser equipment, but also a spare part.

3. Machine bed

For fully automatic laser tube cutting machines, the machine bed with higher stability can also increase the accuracy of daily operations. Therefore, the machine bed is also a major standard for reference to the quality of the automatic laser tube cutting machine.

4. CNC system

The numerical control system is the main operating system of the laser cutting equipment, which can complete the setting of the cutting graphics of the automatic laser tube cutting machine, control the cutting motion of the X, Y, and Z axes, and the output power of the laser. The customer should also increase it when purchasing attention.

5. Motor

Motor is the core component of the automatic laser tube cutting machine motion system, which will affect the quality and production efficiency of product production. Professional automatic laser tube cutting machine manufacturers often configure motors with good performance to help customers produce products.

Applied Materials: Carbon Steel, Stainless Steel, Copper, Brass, Aluminum Alloy, Galvanized sheet, etc

Application Industries: Sheet metal fabrication, Automobile manufacture, Electrical cabinet, Elevator and escalator, Kitchen appliance Metal doors and windows

Igoldencnc ’s over laser metal cutting machines are equipped with the industry's top intelligent CNC system, strong computing power, fast response speed, high compatibility, highly intelligent system, realizing the super stability and consistency in continuous cutting at rated power. Its cast iron bed can work 50 years without deformation.

The laser industry‘s unique pearlite gray cast iron bed

IGOLDENCNC laser’s products help customers quickly improve production efficiency and the cutting quality, and help them expand more business and seize more market share. Up to June, IGOLDENCNC Laser's 10,000-watt laser cutting product sales exceeded 150 sets, leading the global metal laser processing industry to enter a new era. IGOLDENCNC Laser has become the first choice and the most trusted brand for customers who are seeking for cutting machines over 10000-watt.