Views: 11 Author: Site Editor Publish Time: 2021-11-30 Origin: Site

Fiber laser cutting machines for stainless steel with 3000*1500mm working area, which consist of machine tool, motion parts, electrical equipment control parts, and other assist parts. Via control system to operation three axis motion parts, so it can drive to fiber laser cutting head achieve a stable, accurate, and high speed moving; X and Y axis of aluminium stainless steel sheet cutting machine adopt by imported with original packaging high quality and precision HIWIN linear guide rail, working table adopt by square pipe to welding the overall machine, stress relief annealing treat, the max load-bearing of mesa could get 500 KG, it also has universal ball bearing, machine external set up peripheral clamping device, use full enclosed dust proof device, photoelectric sensor, and other precise positioning parts to ensure accuracy of the transmission.

In addition to the daily maintenance of the stainless steel cutting machines, in order to keep the Laser Stainless Steel Cutter in a good working condition, we also need to carry out a series of maintenance work on the machine, such as replacing parts.

1.How to install or replace the optical lens of the laser cutting machine

Before installing the optical lens, please pay attention: wear clean, clean your hands with soap or detergent, and wear white clean and light gloves; it is strictly forbidden to touch the lens with any part of your hand; when taking the lens, you should wear gloves and Take the side of the lens and do not directly touch the coating surface of the lens.

When assembling the lens, do not blow into the lens with your mouth; the lens should be placed on a clean table with a few pieces of lens paper underneath. When taking the lens, you should be careful to prevent bruises and falls, and do not apply any force on the coating surface of the lens; the lens holder where the lens is installed should be clean, and a clean air spray gun should be used to clean the dust and dirt in the lens holder Then, take out the lens and gently put it into the lens holder.When installing the lens to the lens holder, do not use too much force to fix the lens, so as not to deform the lens and affect the quality of the beam.

2. Steps of laser stainless steel cutting machine to clean the lens

Different lenses have different cleaning methods. When the mirror surface is flat and there is no lens holder, use lens paper to clean, such as cleaning the mirror; when the mirror surface is curved or the mirror surface has a lens holder, you should use a cotton swab to clean, such as cleaning the focusing lens.

Steps to clean the lens with lens paper: Use a blowing balloon to blow off the dust on the surface of the lens; clean the surface of the lens with alcohol or lens paper. Do not use dry lens paper to drag directly on the lens surface, but place the lens paper flat.

Put 2 to 3 drops of high-purity alcohol or high-purity acetone on the surface of the lens, and slowly pull out the lens paper horizontally toward the operator. Repeat the above actions several times until the mirror surface is clean; if the mirror surface is very dirty, Fold the lens paper in half 2 to 3 times and repeat the above steps until the mirror surface is clean.This can increase the service life of laser stainless steel cutting machines

Steps to clean the lens with a cotton swab: first use a spray gun to blow off the dust on the mirror surface; then use a clean cotton swab to remove the dirt; use a new cotton swab moistened with high-purity alcohol or acetone to move in a circular motion from the center of the lens to scrub the lens. After wiping for a week, change to another clean cotton swab and repeat the above operation until the lens is clean.

Never use cotton swabs that have already been used for operation; clean the lens with a clean cloth to remove the residual marks on the mirror surface, and be careful not to Scratch the mirror surface; take the cleaned lens to a place with sufficient light to observe. If the reflection of the lens is good, it indicates that the lens has been cleaned.This can reduce the failure rate of the Laser Stainless Steel Cutter.

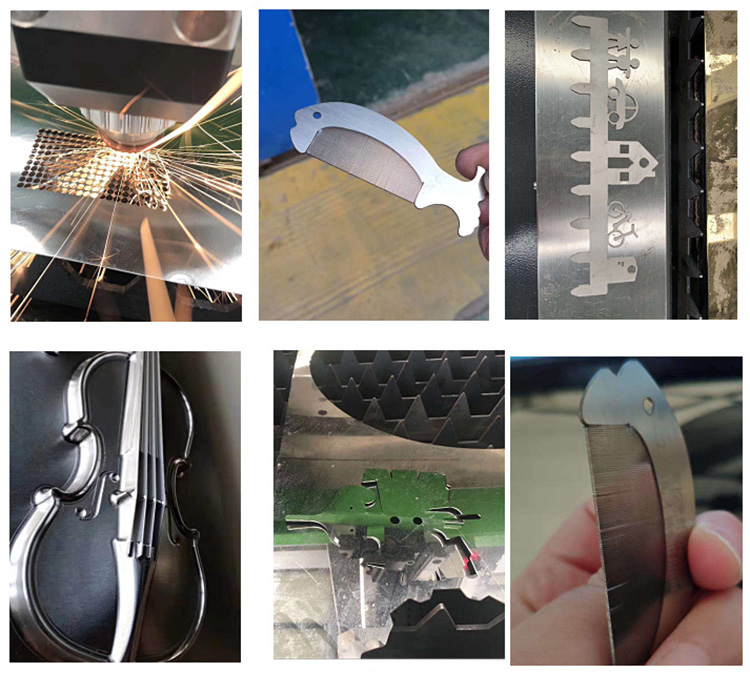

Laser cutting machines for stainless steel Industrial application

1.Application Materials: Fiber Laser Cutting machine is suitable for metal cutting with Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring Steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc

2.Application Industries:Triumph Fiber Laser Cutting Machines are widely used in manufacturing Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal Crafts, Metal Art Ware, Elevator Panel Cutting, Hardware, Auto Parts, Glasses Frame, Electronic Parts, Nameplates, etc.