Views: 12 Author: Site Editor Publish Time: 2022-06-28 Origin: Site

Fiber laser welding machine has become an important production equipment for manufacturing companies, as a kind of high precision equipment, must pay attention to maintenance. Thus, the daily application and protection of 1500w laser welder must be carried out by professional learning and training of staff to carry out the actual operation, otherwise it is easy to cause obvious human factors of destruction. I laser welding machine is widely used in welding industries because its high welding precision and high speed. After long-term use, its welding efficiency may decrease and we need maintain it regularly. So when we using handheld laser welder, how to maintain it?

1. Regularly check and replace the internal circulating water

The secret of the 1500w laser welder to ensure high output efficiency lies in the high purity of the cooling water because the high purity of the cooling water is a key factor to ensure the updated output power and laser life.

The centralized spray gun assembly can achieve better maintenance, and the service life of the fiber laser welding machine is longer. The conductivity of the internal circulating water should be checked once a week, and the deionized water of the internal circulating water should be replaced once a month.

At this time, attention should be paid to the conductivity of the newly injected pure water. Within the specified range. When replacing deionized water, please pay attention to the color change of the ion exchange column in the cooling system.

If the color of the resin in the replacement column changes to dark brown or black, the resin should be replaced immediately.

2. Regularly check the output spot of the laser

In order to better ensure that the output light spot of the laser tends to be stable, the operator needs to check the output light spot of the laser frequently with black photographic paper. If it is found that the output spot is unbalanced or the energy is reduced, the laser resonator needs to be adjusted in time to ensure the quality of the light output by the laser and prevent people from directly viewing the laser as much as possible. daily work.

If you want to operate or debug the fiber laser welding machine, the debugger must be equipped with special laser protective glasses.

In short, the daily maintenance of the handheld laser fiber laser welding machine requires regular inspection of the circulating water in the equipment, and at the same time, the deionized water in the internal circulating water needs to be replaced.

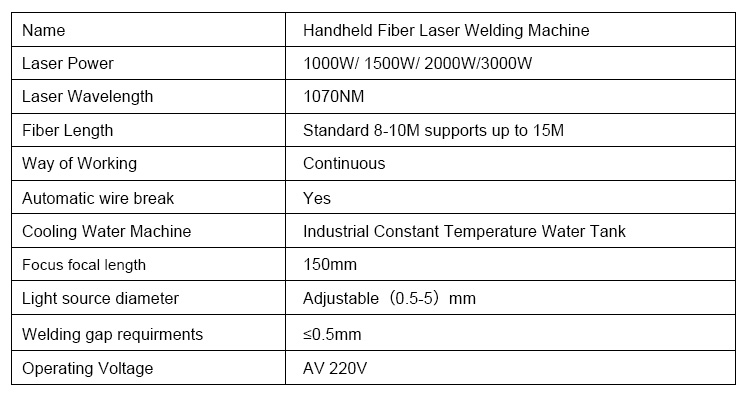

Handheld Laser Welding Machine Parameters:

The welding gun maintenance of the 1500w laser welder:

3.1. Regularly check and replace the contact tip

3.2. Regularly clean and replace the spring hose

3.3. Inspection of insulating ferrule