Views: 26 Author: Site Editor Publish Time: 2021-11-23 Origin: Site

Sheet metal laser cutting machine is a fabrication process which employs a focused, high-powered laser beam to cut material into custom shapes and designs. This process is suitable for a wide range of materials, including metal, plastic, wood, gemstone, glass, and paper, and can produce precise, intricate, and complex parts without the need for custom-designed tooling.

As one of the leading sheet metal cnc laser cutter manufacturers or laser cutters manufacturers, IGOLDENCNC has always upheld the laser cut ideas of Do the Best Within the scope of ability, and provides various affordable and efficient laser cutter projects for our customers.

Maintenance of the lens

Before starting the cnc metal laser cutter, check mirrors to check whether there is dust on the mirror surface or whether the mirror surface is damaged. The maintenance of the lens of the laser cutting machine is very important, and it is very important to ensure the quality of the beam.

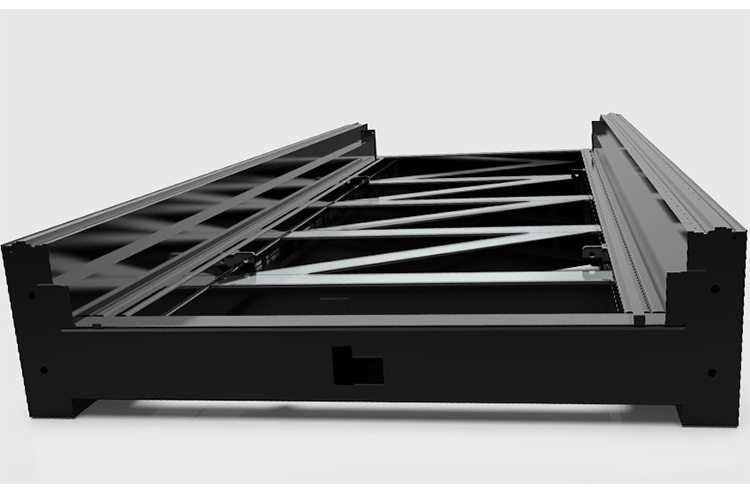

HEAVY-DUTY WELDING BED

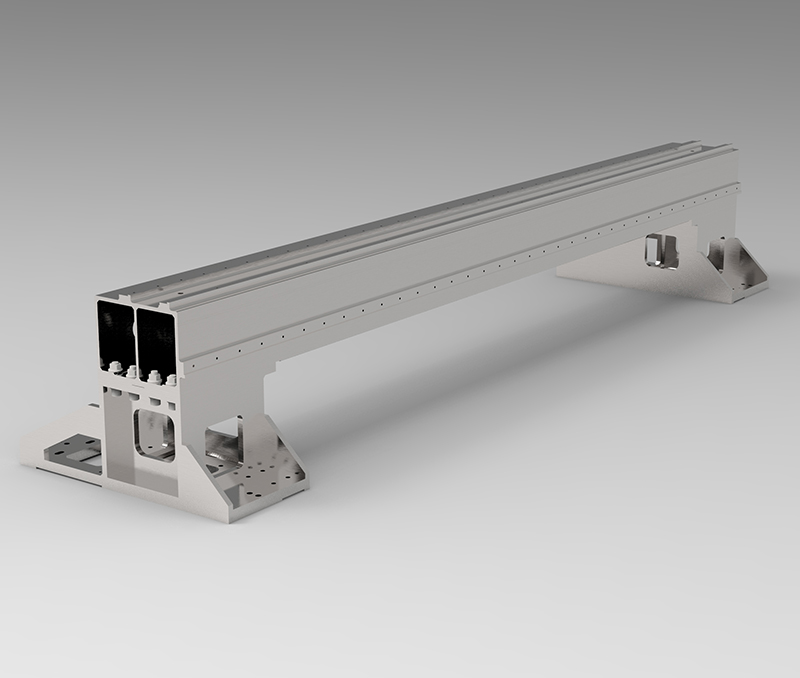

AEROSPACE ALUMINUM EXTRUSION BEAM

AUTO-FOCUS LASER CUTTING HEAD

The lens of the cnc metal laser cutter is easily contaminated by smoke and dust. It is recommended to clean it once a day before starting work. Generally, anhydrous industrial alcohol acetone is used to clean the lenses. Different lens cleaning methods are different. When the mirror surface is flat and there is no lens holder, use lens paper to clean; and when the mirror surface is curved or the mirror surface has a lens holder, please clean it with a cotton swab.

When using the lens, pay attention to focusing on the lens, protecting the lens, QBH head, and other optical surfaces, and do not touch it directly with your hands to prevent scratches or corrosion of the lens.

Maintenance of the cutting head

Before using every day, check whether the laser is emitted from the center of the nozzle, if not, please readjust the calibration.

Before cutting, adjust the height of the cutting head to a suitable drilling position.

When cutting, always observe whether it is cutting. If you do not cut, first raise the cutting head by hand to stop cutting, check whether the cutting parameters are correct, whether the nozzle and the protective mirror are damaged, adjust them, and then return to the uncut state, and then continue cutting.

When cutting, observe whether the cutting piece is turned over or up. If so, take over when the cutting head collides with the workpiece. If the plate is not flat, adjust it to the appropriate drilling height (3-5mm) at any time.

When cutting, observe whether the cutting head catches fire. If it catches fire, stop cutting, check whether the nozzle is worn, and judge whether the focus is changing. If so, increase or decrease the pad according to the situation.

Laser water temperature adjustment

In order to prevent condensation on the laser, the cooling water temperature of the water cooler and the temperature and humidity of the laser protection room should be adjusted in time according to the seasonal temperature and air humidity; antifreeze must be added to the water tank in winter to prevent freezing and freezing of water pipes.

get inquiry

The chiller is used as the cooling equipment of the fiber laser cutting machine. The chiller guarantees the normal operation of the fiber laser cutting machine at a constant temperature. Pay attention to the water temperature when working for a long time. It is recommended that the water temperature is below 35 degrees; in winter, the circulating water should be prevented from freezing and the laser tube from freezing and cracking (antifreeze can be added).

The water inside the chiller needs to be replaced regularly because long-term use is prone to scaling and reduces the cooling effect. Generally, clean the chiller 1-2 times a month, replace the internal circulating water, and use distilled water without impurities, such as pure water or mineral water. But be careful not to use tap water. Learn more: How to prevent laser condensation in summer?

Maintenance of the guide rail frame

Each rail rack needs to be cleaned regularly to remove dust and other debris to ensure the normal operation of the equipment. The frame should be wiped and lubricated frequently to ensure that the lubrication is free of debris.

In addition, always check the steel belt to ensure that the steel belt is tight. Regularly check the straightness of the track and the verticality of the machine. If abnormalities are found, maintenance and adjustments will be carried out in time, usually at an interval of 6 months.

Attention to the working environment

The environment where the machine is located must be pollution-free, free from interference and influence from strong electricity, strong magnetism, etc. Pay attention to anti-vibration and anti-loose: the cutting machine is particularly sensitive to vibration. The working environment should be far away from places with vibration sources such as punches and heavy objects. If the connection is loose, it is recommended to install anti-vibration pads and re-reinforce.

In addition, pay attention to anti-interference and anti-leakage: the electromagnetic environment of the cutting machine mainly includes the surrounding electromagnetic field, the quality of the power supply, and the interference of signal electrical noise.

get inquiry

Daily maintenance requirements

A. Check and clean the workbench every day to keep the laser and laser cutting machine clean and tidy.

B. Check whether the X, Y, and Z axes can return to the origin every day, and check whether the position of the striker of the origin switch is offset.

C. Check whether the connecting wire is tight and disconnected every day, and check whether the fan of the control box is normal.

D. Clean the X-axis screws and Y-axis screws every week and then add oil.

E. Check whether the fixing screw of the screw nut is damaged and whether the joint between the water pipe and the air pipe is damaged or blocked.

The Sheet metal laser cutting machine has the advantages of fast cutting speed, good cutting quality, high cutting accuracy and completely inheriting the three characteristics of laser cutting technology. Compared with other machines, it has the following advantages:

Simple operation and stable performance

The Sheet metal laser cutting machine only needs simple training for operators to get on duty. Among the CNC laser cutting machine manufacturers, new technologies are constantly developed, and some equipment can also be added with automatic loading and unloading devices, which saves labor costs and makes the application widely become the first condition.

The material to be processed is not constrained by shape

CNC laser cutting machine is not affected by the hardness of materials, any shape of graphics, only need to import drawings can be cut, also do not need to make mold.

It adopts the processing mode of non-contact test without damaging the processing materials

The CNC laser cutting machine can complete the cutting process without contacting the workpiece surface. It also has the auxiliary gas function, which can make the cutting surface smooth, the cutting gap is very narrow, the material is saved greatly, and the effect is improved.

Widely used

Sheet metal laser cutting machine can be used in many industries, different power laser, can meet multi-purpose, multi thickness cutting, can be used to cut carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized plate, brewing washing plate, aluminum zinc plate and other materials.