Views: 8 Author: Site Editor Publish Time: 2021-10-07 Origin: Site

The Laser Welding Machine is an important aspect of laser process technology application. The laser welding process is thermal conduction, i.e. the laser radiation heats the surface of work piece, and the surface heat diffuses to the interior through thermal conduction and melts the work piece by controlling the width, energy, peak power and repeating frequency of laser pulse to form specific molten pool. Because of its unique advantage, it is widely used in the process of gold and silver jewelry and welding of Engg parts. These welding machines can be used Manually with Hand Held Welding Head as well as can attached with Automation Systems or Robotics as per applications.

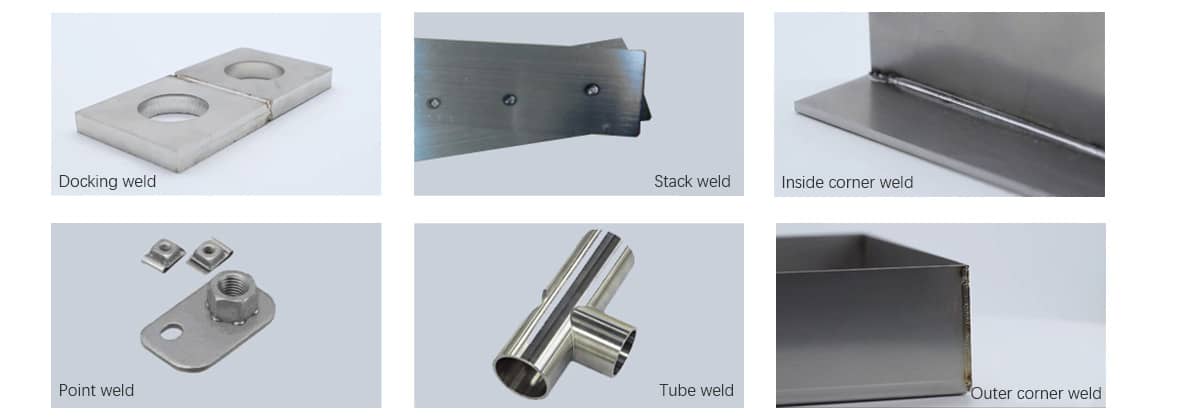

1. Flexible and diverse optical fiber welding methods

Relatively speaking, the high-power fiber laser welding machine can realize precise welding of a variety of materials, especially for the welding of some precision parts. There are many welding methods available for fiber laser welding machines, for example, spot welding, overlap welding, butt welding and sealing welding can be realized. It can be seen that the welding methods of fiber laser welding machines are diversified. For the same item, different welding methods can be used for welding. Users only need to select a more suitable welding method to better ensure the welding effect.

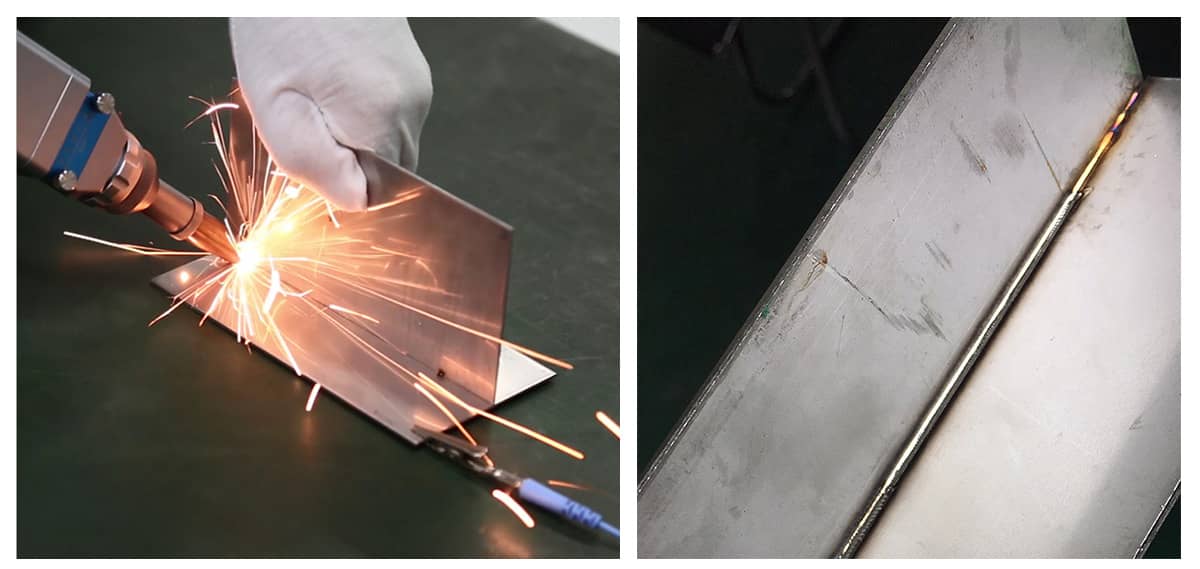

2. The fiber welding effect is good, and the welding seam is small

The fiber laser welding machine has a large weld depth ratio, a small specific energy, a small heat-affected zone, a small deformation of the weldment, and the welded workpiece is flat and beautiful. It is especially suitable for the welding of precision and heat-sensitive parts.

3. The material to be welded is not limited

The laser beam emitted by the metal laser welding machine can quickly melt different types of metal materials, even metal materials that are difficult to weld with traditional welding machines, such as carbon steel, stainless steel, aluminum structural steel, copper and other metals, laser welding machines can also easily" Handle".This feature also makes the laser welding machine applicable to a wider range of industries.

4. Wide use, strong function

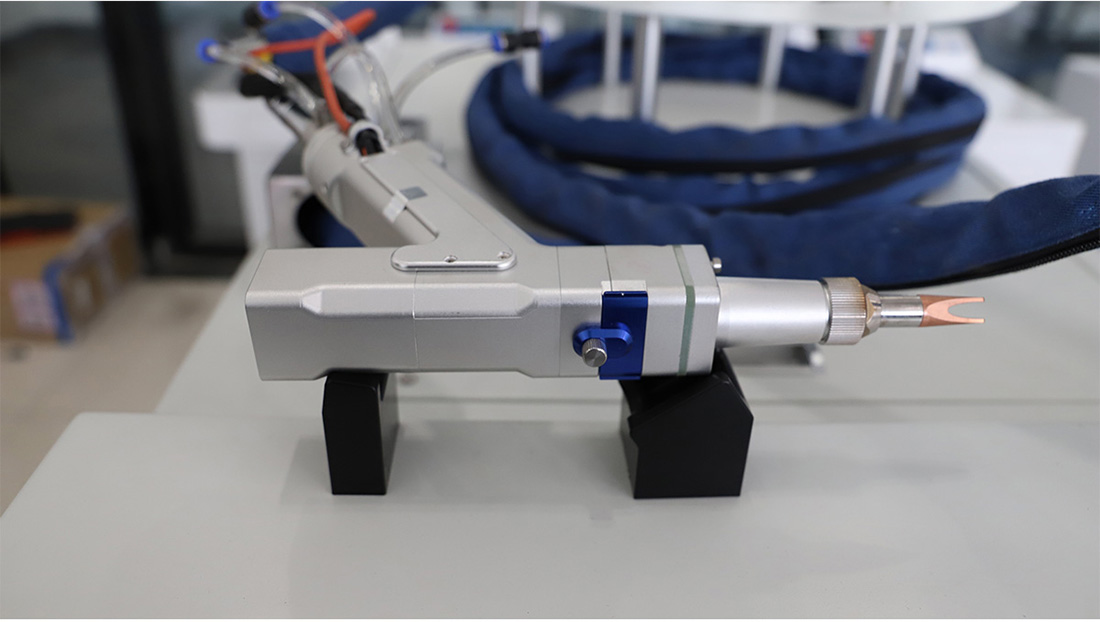

The flexible optical fiber transmission device can not only precisely weld various devices on the host, but also repair and weld large workpieces far away from the host, which meets the various needs of different customers.

5. High work efficiency

The fiber laser welding machine has a high degree of automation and a simple welding process. The non-contact operation method can meet the requirements of cleanliness and environmental protection. Processing workpieces with fiber laser welding machines can improve work efficiency. The finished workpieces have beautiful appearance, small welds, large welding depths and high welding quality.

6. Long service life

The service life of the laser can reach 100,000 hours. Because of the high-tech, high-efficiency and pollution-free combined light-concentrating cavity, the laser photoelectric conversion efficiency, light output power and optical quality have been greatly improved; at the same time, the gold-plated reflective layer has no direct contact with the cooling medium to ensure that the gold-plated reflective layer is not in direct contact with the cooling medium. The layer is not subject to any pollution, thereby prolonging the service life of the cavity and the xenon lamp and reducing the operating cost.

7. Low maintenance cost

The fiber laser welding machine can output multiple optical paths, which can realize energy splitting, and evenly distribute the laser energy output by the laser to the output fibers; at the same time, it can also realize time splitting, and output the laser energy to each fiber at different time intervals. Laser welding processing at different times and locations. Therefore, equipment costs can be saved.

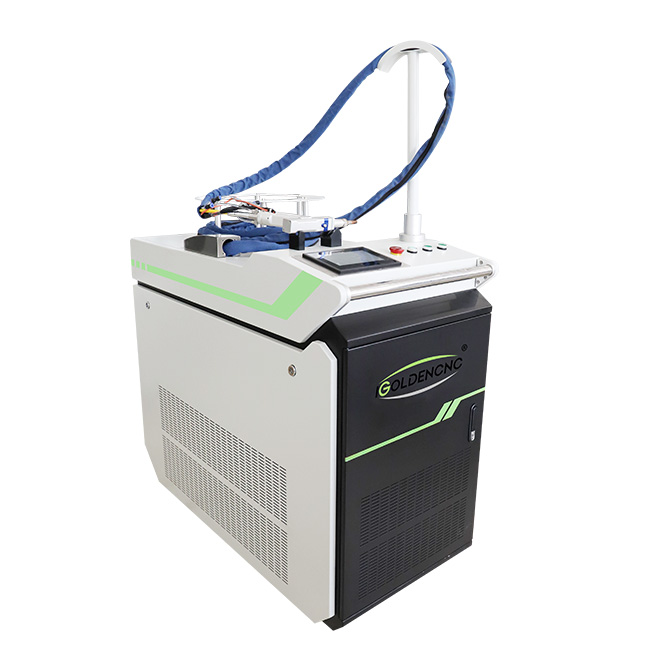

Machine Configuration

The handheld laser welding machine can perform long-distance laser welding of largeworkpieces. The heat affected area is small during welding, and it will not cause deformation, blackening, and traces on the back of the workpiece.

The connection depth is large, the welding is firm, and the melting is sufficient.

There is no depression in the joint between the raised part of the molten material in the bath and the substrate!

The welding speed is fast, 2-10 times faster than traditional welding, and one machine can save at least 2 welders a year.

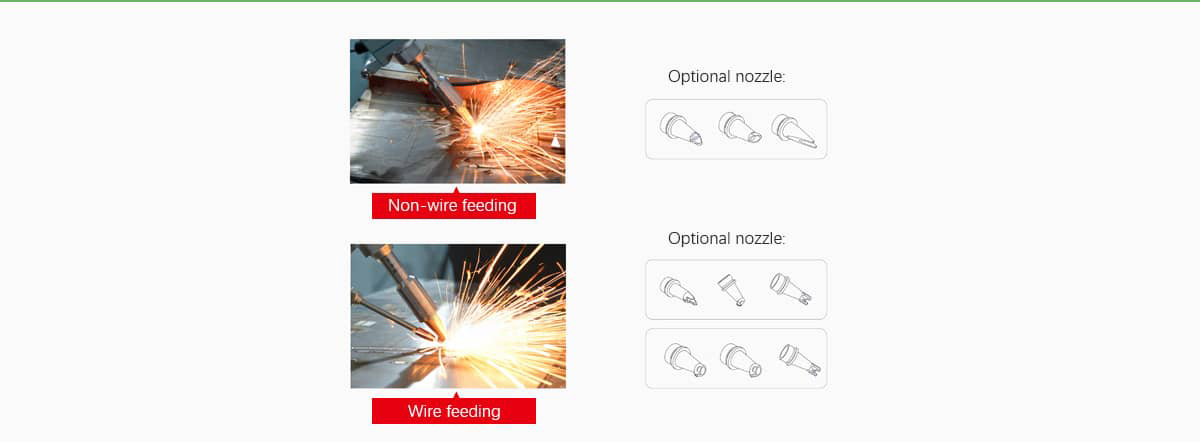

iGoldencnc’s handheld laser welding machine has two welding modes.

Customers can choose between wire feeding or non-wire feeding according to their own products.

The switching is simple and practical.

Industrial Applications:

The laser welding machine widely used in cabinet kitchen, staircase elevator, shelf, oven, stainless steel door, hardware, metal almirah, commercial kitchens, auto parts and window guardrail, distribution box, stainless steel furnishings and other industries.

Scope of Application