Views: 10 Author: Site Editor Publish Time: 2021-09-02 Origin: Site

Robot Laser Welding Machine is a high-energy-density laser beam as a heat source, which locally heats the material in a small area and melts the material to form a specific molten pool to achieve the effect of welding. Laser welding is mainly used for welding of thin-wall materials, precision parts, etc., which can realize spot welding, splicing welding, seal welding, overlap welding, etc.

The combination of laser welding and robot, has the advantage of automation intelligence, high flexible, and can be used for welding material of complex surface.

1. The diameter of the solder joint is small, and the heat affected area is small,

which will not cause deformation of precision products.

2.Can weld small and fine areas, suitable for all sizes of processed parts. After welding,

the workpiece does not change color, no pores and trachoma.

3.Can directly carry out grinding, polishing and EDM treatment without the influence of substrate structure deformation.

4. Hand-held laser head can be used with automatic workbench, industrial intelligent manipulator, perfect stability and long laser life

5. Excellent beam quality, precision and high efficiency. Fast processing speed,high processing precision, environmentally friendly and no consumables. built-in software is powerful and compatible.

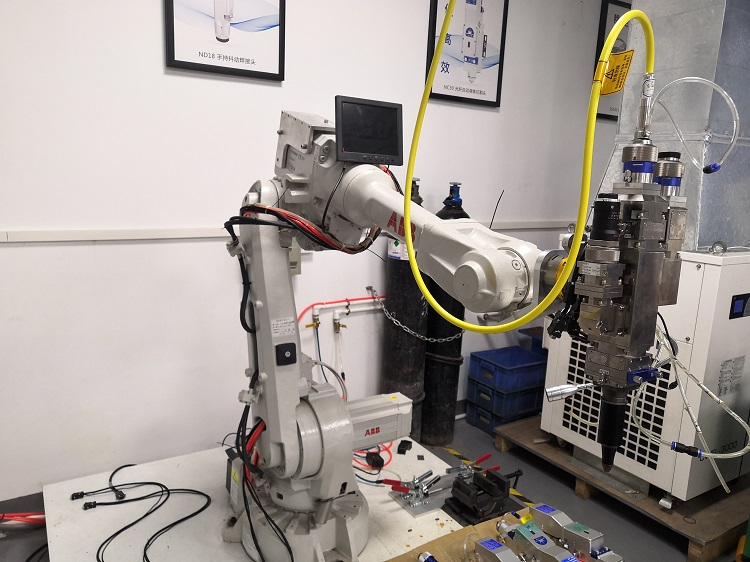

Details Images of 2000W Robot Laser Welding Machine:

1. The robot has six-axis linkage, high positioning accuracy, large processing range, and easy welding of three-dimensional workpieces.

2. Compared with the traditional argon arc welding, the laser welding speed is increased by 5 to 10 times, and the power consumption and the consumption of consumables are lower, and the welding quality is very stable.

3. The heat affected area of welding is smaller, which can better guarantee the quality of welding products.

4. Robot laser welding has good adaptability to the size and shape of welding materials and welding parts, and can realize automatic control and long-distance welding

Advangtages of Robot Laser Welding Machine:

A. The machine is easy to handle and don't need the professional welder.

B. With 8-15m fiber wire, Can weld long-distance and large-area parts.

C. High quality and very stable: With a long lifespan to 100000 hours and free of maintance.

D. High efficiency: more than 5 times of the TIG welding with low energy consumption.

E. Various welding proceses: jam welding, seal welding, spot welding, stitch welding and overlap welding .

F:Inappreciable heat-affected zone, little deformation good-looking smoothly welding seam.

G. Little remedial work after welding, high-quality of welding line, precise control of positioning accuracy, small spot focus and automated welding

H: Low cost, no consumables, energy saving and enviroment protection.

I: Can support the different welding wires for stainless steel, Aluminum and Copper

Robot Laser Welding Machine Application:

3D robot laser welding machine is used in manufacturing industry, metallurgy industry, automobile industry, electronic industry, biomedicine, household appliances manufacturing, processing tools, IT manufacturing, food machinery, diamond tools, welding, welding gear, surface treatment of metal materials, decorative advertising, laser processing services and other processing machinery manufacturing industry.

Scope of Application

Suitable for welding of stainless steel, iron sheet, aluminum, copper, alloy, steel, diamond equivalent materials or dissimilar materials, cabinets, kitchens, stair elevators, shelves, ovens, stainless steel doors and windows guardrails, distribution boxes, Stainless steel household and other industries.