Views: 28 Author: Site Editor Publish Time: 2022-04-09 Origin: Site

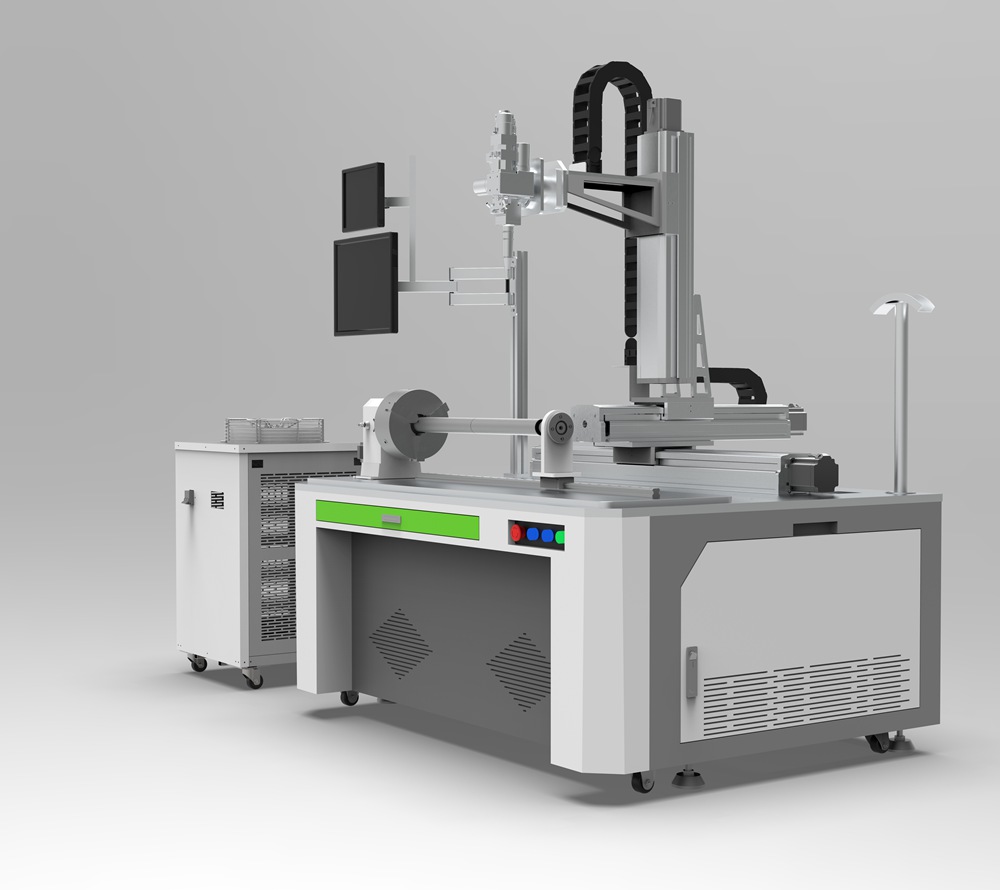

This is an automatic laser welding machine, mainly suitable for mass production. And it can realize spot welding, butt welding, overlap welding, sealing welding and other welding processes for thin-walled materials and precision parts. It has the advantages of wide application range, high precision and fast speed.The laser beam of the optical fiber transmission light weld 1500 laser welding system can realize the splitting of time and energy, and can process multiple beams at the same time, which provides conditions for more precise welding.

IGOLDENCNC is a market occupied by technology, excellent product quality and excellent service.

1.Excellent laser beam quality,fast welding speed, the welding joint is firm and beautiful,we provide efficient welding project to the user;

2.Controlled by PC, special software assisted, easy to learn, the workpiece can be used for plane trajectory movement, welding any point, straight line, circle, square or any plane graphic composed of straight line and arc;

3.High electro-optic conversion rate, low energy consumption, no consumables, small volume,Can save a lot of processing cost for users after long term use;

4.It can be continuously and stably processed for 24 hours to meet the needs of industrial mass production and processing;

5.CCD liquid crystal monitoring and observation system, can clearly observe product positioning and welding effect according to red light indication;

6.The welding line is fine, the welding depth is large, the taper is small, the precision is high; the appearance is smooth, flat and beautiful;

7.Fiber output, can be equipped with robot or assembly line;

8.We have strong ability to customize special models for our customers., and can be customized according to customer needs;

9.Provide multi-language display (Chinese simplified, English, etc.) to support Fiber Laser source: Adopting famous brands (Raycus / JPT/Max. And Germany IPG) the photoelectric conversion rate is greatly improved, laser power is enhanced, has better welding effect, can according to the needs of customers with different configurations to meet customer needs.

Automatic Welding Equipment Parameters

Technical index | Technical Parameters | ||

Model | iGWL-AW- 1000 | iGWL-AW- 1500 | iGWL-AW- 2000 |

Laser power | 1000W | 1500W | 2000W |

Laser wavelength | 1080±10nm | ||

XYZ Working stroke | 1000*400*500mm | ||

X/Y/Z Axis positioning accuracy | ±0.025mm | ||

X/Y/Z Axis Repositioning accuracy | ±0.02mm | ||

Laser working method | CW/Modulated | ||

Width of galvanometer | Line 0.5-6mm/ Circle 2mm | ||

Thickness of welding material | ≤4mm | ≤6mm | ≤8mm |

Welding gap requirements | ≤0.3mm | ||

Voltage | 380V±10% | ||

Total power | ≤8kw | ≤10kw | ≤12kw |

Gross weight | 700kg | 800kg | 900kg |

best stainless steel welding machine Application:

available for aerospace, rail transport, 5G communication, kitchen hardware, metal sheet, precise instrument and auto parts, etc. CCD optional