Backpack Laser Cleaning Machine Description:

The comfortable back frame and lightweight construction allow longer working time. The mobile laser system is fully operational, even without on-site power, thanks to battery operation.Cleans smoothly, quickly and discreetly with no damage to the base metal or original surface.

Handheld Fiber Laser Cleaning Machine Feature:

Optional lithium battery: allows it to work anywhere.

Red dot indicator: allows easy and precise focus.

Portable design: ergonomic design allows you to carry it without damaging your shoulder

Lightweight:18KGkg weight makes it easy to carry it on your back for work

Product advantages:

1. Portable design: compact structure, wearable.

2. High efficiency cleaning: high efficiency of laser cleaning, saving time;

3. Non-contact: laser cleaning without grinding and non-contact;

4. Pollution-free: do not need to use any chemical agents and cleaning fluid, easily solve the environmental pollution problems caused by chemical cleaning;

5. Strong expansibility: replaceable field mirror, changing the depth of zoom, wider width of laser cleaning.

Backpack Laser Cleaning Machine Parameters:

| Model | iGCL-MOPA(B)-100W |

| Supply Voltage | Lithium battery or single-phase 220V±10%;

50/60Hz AC |

| Average laser power | ≥100W |

| Laser type | Fiber-optic laser |

| Frequency adjustment range | 1-3000kHz |

| Fiber length | 3m(customizable) |

| Cooling method | Air cooling |

| Scaning range | 0-120mm, continuously adjustable;

Dual axis supports 7 scanning modes |

| Main body size | 336mm (L) * 129mm (W) * 400/500mm(H) |

| Total weight | 18KG |

| Cleaning head weight | <0.9KG

|

Portable Handheld Fiber Laser Cleaner Configuration:

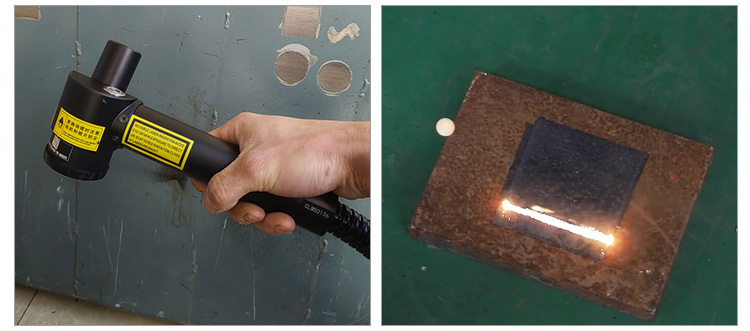

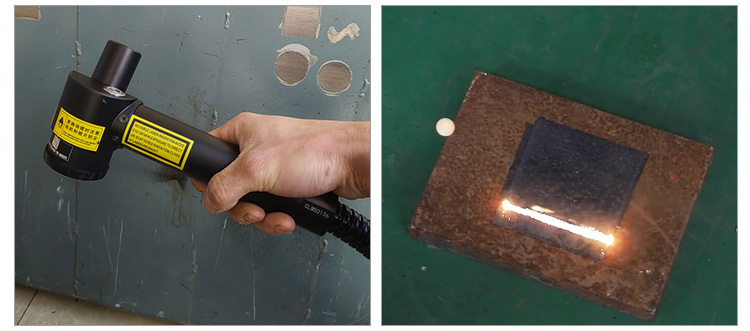

Cleaning machine laser head:

High cleaning cleanliness It can accurately locate and clean contact cleaning, protect thesurface of brittle materials,and effectively remove micron-level pollution particles; green and environmentally friendly, no consumables are required.

This not only means that laser cleaning is effective, but the cleaning process is environmentally friendly.

In addition, it does not use chemical cleaning agents, thus avoiding the damage caused by chemical corrosion to the material.

Intelligent Control Panel

Full touch screen operation interface, adjustable multiple cleaning modes, easy and convenient to operate, saving your debugging time.

The high-intensity light pulse generated by the laser that calculates and sets the threshold value forms an interaction between the short-pulse laser and the contaminated layer, resulting in a photophysical reaction.

The beam is absorbed by the contaminated layer on the surface to be treated. The absorption of large energy forms a rapidly expanding plasma (highly ionized unstable gas), which generates shock waves.

The shock waves turn pollutants, oxides, etc. into fragments and gases and are removed to complete the cleaning.

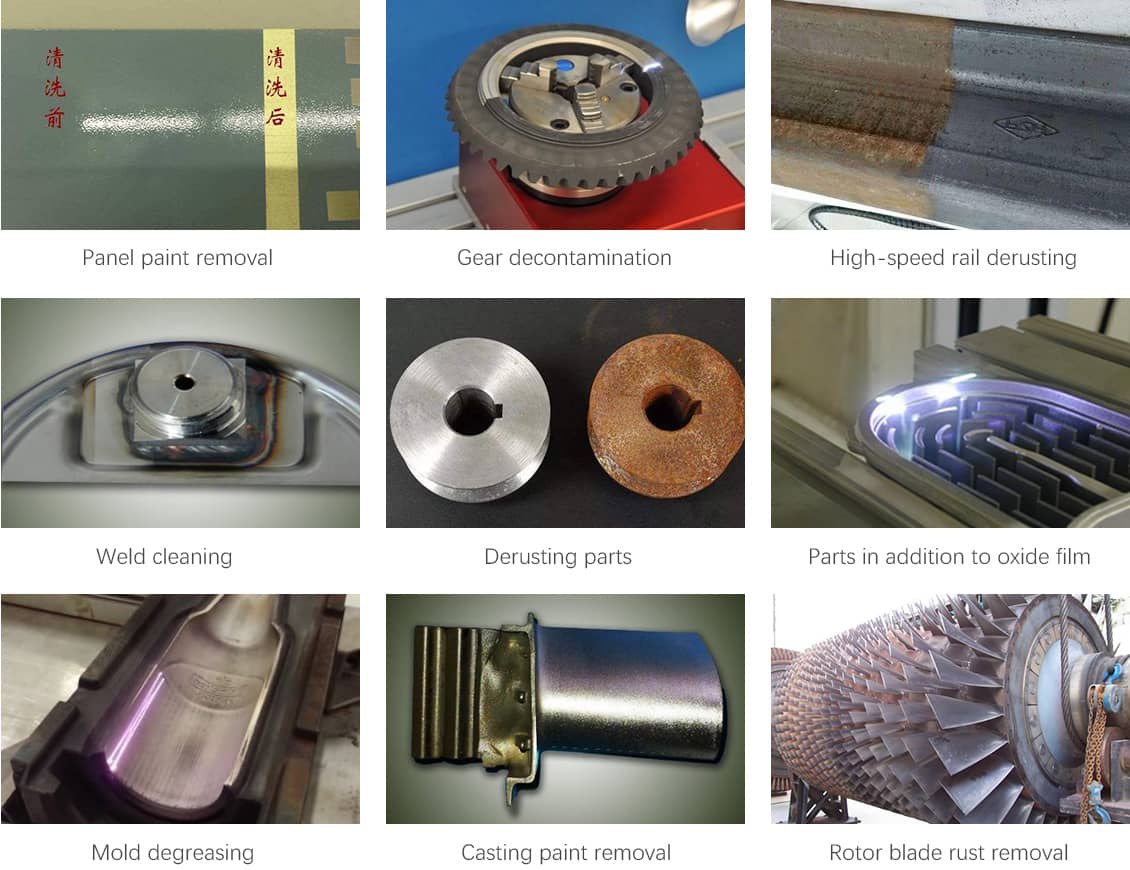

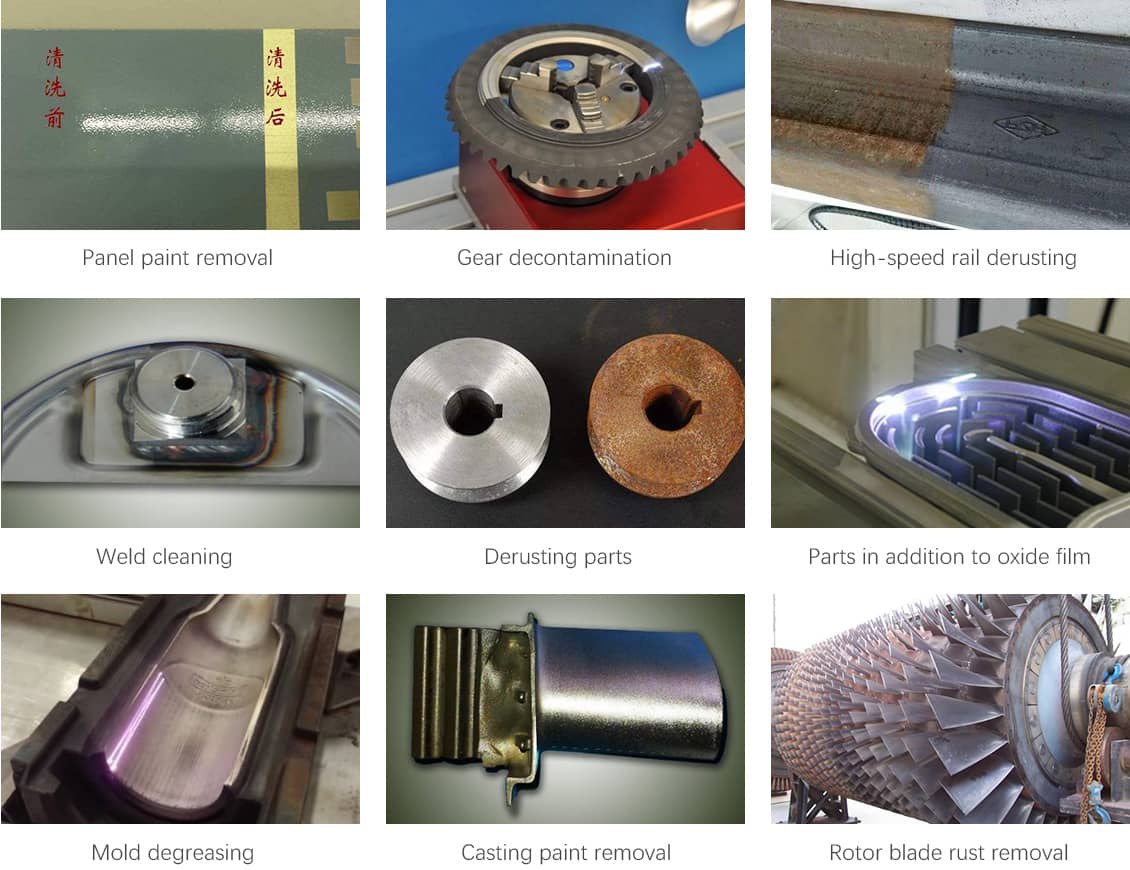

Fiber Laser Cleaning Machine Applications

Application Field

1. Rust removal from metal surface.

2. Paint removal from metal surface.

3. Clad layer and coating removal.

4. Oil fouling, blot, and dirt cleaning.

5. Metal weld discoloration removal.

6. Stone surface cleaning.

7. Rubber mold damage-free cleaning.

Application Industry

Manufacturing plant, construction works, machinery repair shops, advertisement, energy & mining, building material shops, ship industry, auto parts, rubber mold, high-end machine manufacturing, tire molde track, environmental protection industry.

iGOLDENCNC Factory View

Customer Visiting

iGOLDENCNC Service

| Pre-sales |

| > Free pre-sale consultation |

| > Free sample testing |

| > Professional CNC solutions |

| > Customer reception |

| > Fast delivery within 7 days(Available in stock) |

| > Customized machines delivered within 30 days |

| After-sales |

| > 2-year warranty |

| > Fast feedback and after-sales service in 12 hours |

| > Fast spare parts and technical assistance |

| > Free training services |

| > Special design, customized, OEM order |

English

English