iGCL-HC

iGOLDENCNC

| Availability: | |

|---|---|

The 1000W, 1500W, and 2000W laser cleaning machines are high-powered laser cleaning tools used for removing contaminants and coatings from a variety of surfaces. These machines use a laser beam to vaporize and remove unwanted materials from the surface being cleaned, without damaging the underlying material.

The power of the laser cleaning machine is measured in watts, with higher wattage machines being capable of faster cleaning speeds and the ability to remove thicker coatings. The 1000W, 1500W, and 2000W laser cleaning machines are commonly used in industries such as aerospace, automotive, and electronics manufacturing.

The laser cleaning process works by emitting a high-powered laser beam that is focused on the surface to be cleaned. The laser energy is absorbed by the contaminants or coatings on the surface, causing them to be vaporized and removed from the surface. The laser cleaning process is non-contact and does not produce any waste, making it a more environmentally friendly option compared to traditional cleaning methods.

China fiber laser cleaning System

With combination of fully enclosed optical path and optimise laser beam system for cleaning purpose. Through high-energy pulse laser collected on the surface of object, with the principles of plasma blasting, high energy pulse excitation and complex photochemical reactions, and by controlling the effective focal length of the laser beam to achieve cleaning process while avoid surfaces damage.

Some of the benefits of using a high-powered laser cleaning machine include:

Non-contact cleaning: The laser beam does not physically touch the surface being cleaned, reducing the risk of damage and ensuring a clean and consistent surface finish.

Precision cleaning: The laser beam can be precisely controlled, allowing for precise and accurate cleaning of the surface.

Faster cleaning speeds: The high-powered laser allows for faster cleaning speeds, resulting in increased productivity and reduced labor costs.

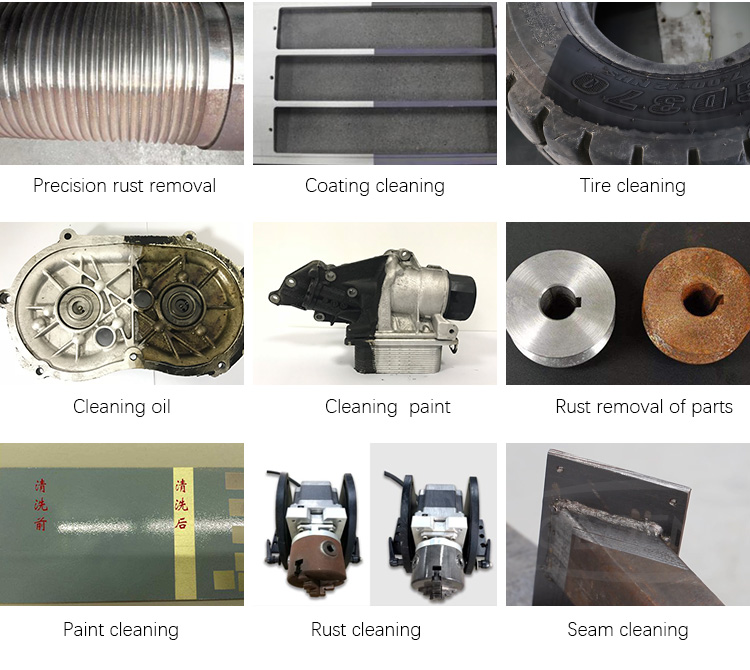

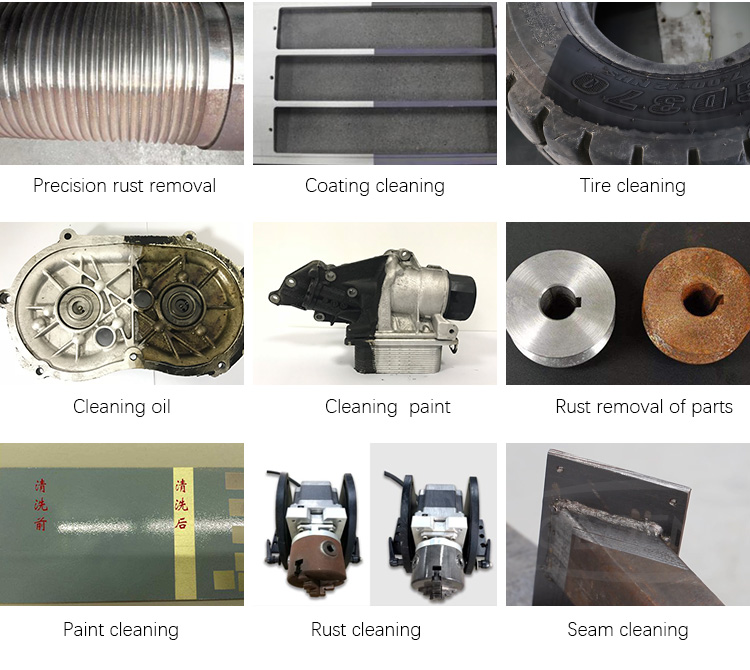

Versatility: The laser cleaning machine can be used on a variety of surfaces, including metals, plastics, and composites, making it a versatile tool for a range of cleaning applications.

Application:

It can clean the mold by using top-hat beam pulse, without damage on base material.

It can be applied to industry rust removal with high efficiency, by using CW laser cleaning.

It can clean large components with thick resin, oil and grease by using recombination laser, such as rail, train axle, etc.

There are different types of laser cleaning machines available, with varying power levels and wavelengths. The power of the laser is measured in watts, with higher power machines being capable of faster cleaning speeds and the ability to remove thicker coatings. The wavelength of the laser beam can also be varied, allowing for greater control over the cleaning process and the ability to target specific materials.

The 1000W, 1500W, and 2000W laser cleaning machines are high-powered laser cleaning tools used for removing contaminants and coatings from a variety of surfaces. These machines use a laser beam to vaporize and remove unwanted materials from the surface being cleaned, without damaging the underlying material.

The power of the laser cleaning machine is measured in watts, with higher wattage machines being capable of faster cleaning speeds and the ability to remove thicker coatings. The 1000W, 1500W, and 2000W laser cleaning machines are commonly used in industries such as aerospace, automotive, and electronics manufacturing.

The laser cleaning process works by emitting a high-powered laser beam that is focused on the surface to be cleaned. The laser energy is absorbed by the contaminants or coatings on the surface, causing them to be vaporized and removed from the surface. The laser cleaning process is non-contact and does not produce any waste, making it a more environmentally friendly option compared to traditional cleaning methods.

China fiber laser cleaning System

With combination of fully enclosed optical path and optimise laser beam system for cleaning purpose. Through high-energy pulse laser collected on the surface of object, with the principles of plasma blasting, high energy pulse excitation and complex photochemical reactions, and by controlling the effective focal length of the laser beam to achieve cleaning process while avoid surfaces damage.

Some of the benefits of using a high-powered laser cleaning machine include:

Non-contact cleaning: The laser beam does not physically touch the surface being cleaned, reducing the risk of damage and ensuring a clean and consistent surface finish.

Precision cleaning: The laser beam can be precisely controlled, allowing for precise and accurate cleaning of the surface.

Faster cleaning speeds: The high-powered laser allows for faster cleaning speeds, resulting in increased productivity and reduced labor costs.

Versatility: The laser cleaning machine can be used on a variety of surfaces, including metals, plastics, and composites, making it a versatile tool for a range of cleaning applications.

Application:

It can clean the mold by using top-hat beam pulse, without damage on base material.

It can be applied to industry rust removal with high efficiency, by using CW laser cleaning.

It can clean large components with thick resin, oil and grease by using recombination laser, such as rail, train axle, etc.

There are different types of laser cleaning machines available, with varying power levels and wavelengths. The power of the laser is measured in watts, with higher power machines being capable of faster cleaning speeds and the ability to remove thicker coatings. The wavelength of the laser beam can also be varied, allowing for greater control over the cleaning process and the ability to target specific materials.