Views: 34 Author: Site Editor Publish Time: 2022-02-07 Origin: Site

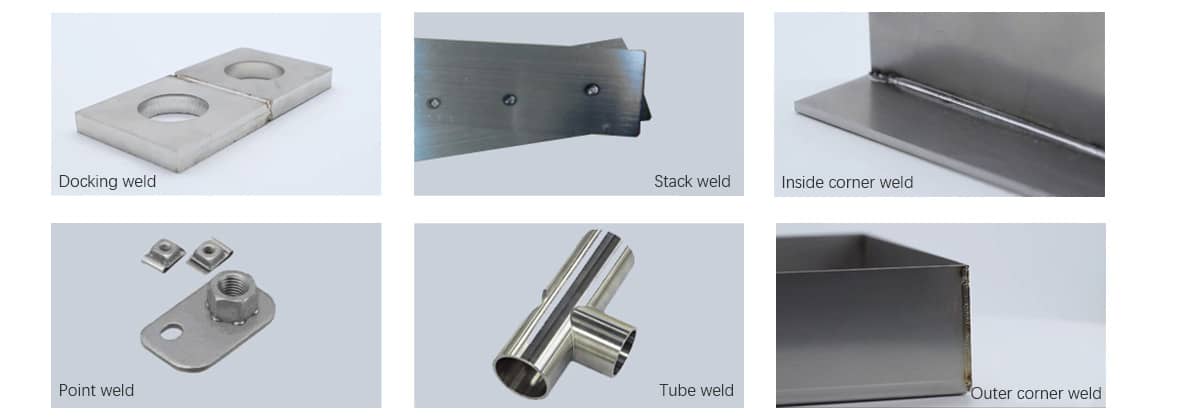

laser welder currently ranks among the top manufacturers in the world in the production and sales of lightweld 1500 laser welding system. With in-depth welding technology research and development and complete and mature supporting capabilities, Raytu provides suitable laser welding processing solutions for various industries. Laser welding solution is mainly aimed at welding thin-walled materials and precision parts, and can realize spot welding, butt welding, stitch welding, sealing welding, etc. Using high-energy laser pulse to heat the material in certain area and the energy of laser radiation diffuses into the material through heat conduction, then the material will be melted to form a specific molten pool.

Hand-held laser welding machine fills the gap in the laser equipment industry, subverts the traditional working mode of laser welding machine and replaces the previous fixed optical path with hand-held, which makes welding more flexible and convenient even with a long welding distance. It also makes possible that laser welding can be operated outdoors.

laser welder is mainly aimed at laser welding of large workpieces in long distance by overcoming the limitations of the worktable's space. The heat-affected area during welding is small, and it will not cause any deformation, blackening, and traces on the back. The welding depth is large as it’s fully melted. It can not only realize thermal conduction welding, but also continuous deep penetration welding, spot welding, butt welding, stitch welding, sealing welding, seam welding, etc. It has the advantages of simple operation, beautiful welding seam, fast welding speed, and no consumables. It can be perfect for welding thin stainless steel plates, iron plates, galvanized plates and other metal materials.

Fabricated steel structure enclosing the laser generator, system controller, panel displays and interface electronics

W 316 mm, D 641 mm, H 534 mm (12.5 x 25.2 x 21 ins)

Integrated 5 meter (˜16 ft) umbilical connection to the Handheld Laser Welding Head

Easy-carry handles

Laser Generator 1500 W CW air cooled, Ytterbium Fiber Laser System housed within the Base Unit

50 micron diameter fiber with 5 m (˜16 ft) fiber delivery to the head

Power adjustable from 10% to 100% of maximum output power

Class-1 collinear red guide beam

Industrial grade controller housed within the base unit

Provides control of all system functionality, laser parameters, gas flow, and monitoring of safety interlock circuits.

Interface via front panel controls and Ethernet port web-page GUI with programs selection

Front Panel Controls

Rotary knob controls and displays for Laser Power, Wobble Length and Wobble Frequency

Touch button access to 70 Stored Process Mode memory locations

System status indicators

System enable keyswitch.

Emergency Off (EMO) button

Handheld Laser Welding Head

Optic configuration to deliver on-target beam diameter of 150 um (0.006 ins)

Focal Length 120 mm

On-axis red guide beam

Wobble function: Linear beam scanning. Length 0-5 mm, Frequency 0-300 Hz

2-Position trigger control

Integrated welding part touch safety sensor

Integrated process gas delivery (Flow controlled by Base Unit)

Interchangeable Precision welding nozzle

Rear Panel Connections

AC Power: 220V, 1 Ph, 50/60 Hz, <20 Amp.

Welding Head I/O:

Workpiece Clamp Circuit:

Process gas input ½” hose - Customer responsibility

Process gas output. (Included with welding head umbilical)

Safety Interlock and I/O. - Customer responsibility

RJ-45 Ethernet connection- customer configuration and status port

Included Accessories

Air-Cooled Base Unit

5 m (16 ft) IPG Laser Welding Gun

5 m (16 ft) Workpiece Clamp

(4) Welding Nozzle Tips

(5) Cover Slides

Welding helmet with IR shield

Laser safety glasses OD 6+

3 m (10 ft) CAT 6 Ethernet Cable

Getting Started Guide

Laser Welding Safety

fiber laser welder might be different than traditional arc welding, but the processes do have some overlap. A welder still needs to wear nonflammable clothing with long sleeves, welding gloves, and a welding helmet. But before the shield comes down over the welder’s face, he or she will need to put on a pair of laser-safe glasses, which provide advanced protection and allow the welder to see the weld pool through the welding hood lens. This power source is producing a Class IV laser after all.

Any manufacturing company that employs hand-held laser welding also will want to provide a laser-safe enclosure to protect others in the shop. This could be a room with door switches or a more typical cell designed with light curtains or pressure pads, like a robotic welding cell. In either situation, when people enter the work area when they aren’t supposed to be there, the laser power source immediately shuts off.

The system was designed with an interlock that requires the welding head tip to be in contact with the material during welding. If the tip is not touching the part, the laser shuts off. This ensures the laser is aimed at the metal workpiece. Also, the weld gun requires a two-step process to be used: a button to enable operation and another button to fire up the laser.

Compared with other welding technologies, the main advantages of laser welding are:

1. Fast speed, large depth and small deformation.

2. It can be welded at room temperature or under special conditions, and the welding equipment is simple. For example, when the laser passes through the electromagnetic field, the beam will not shift; the laser can be welded in vacuum, air and certain gas environments, and can be welded through glass or materials that are transparent to the beam.

3. It can weld refractory materials such as titanium, quartz, etc., and can weld heterogeneous materials with good results.

4. After the laser is focused, the power density is high. When welding high-power devices, the aspect ratio can reach 5:1, and the highest can reach 10:1.

5. Micro welding is possible. The laser beam can obtain a small spot after being focused, and can be accurately positioned, which can be used in the assembly welding of micro and small workpieces that are mass-produced automatically.

6. It can weld hard-to-access parts, and implement non-contact long-distance welding, which has great flexibility. Especially in recent years, the use of optical fiber transmission technology in YAG laser processing technology has made laser welding technology more widely promoted and applied.

7. The laser beam is easy to realize the beam splitting according to time and space, and can perform multi-beam simultaneous processing and multi-station processing, which provides conditions for more precise welding.

Scope of Application