Views: 46 Author: Site Editor Publish Time: 2022-01-06 Origin: Site

Wooden door design cnc router machine uses a gantry structure to meet the needs of the feeding height. The heavy duty steel structure confrim the stability of the machine. The guide rail adopts square guide rail, the supporting surface is stable. Rack transmission is smooth, ensures no deformation and vibration for long time and high speed working. In this way, the precision and beauty of carving can be guaranteed when carving wooden doors, thereby greatly imporve the efficiency of wooden door.

The manual wooden door is depends on the workers. The output is low and the price is high. Wooden doors made by wood carving machine now can increase production while ensuring product consistency. The wooden door design cnc router machine is easy to operate and it is more handy during use.

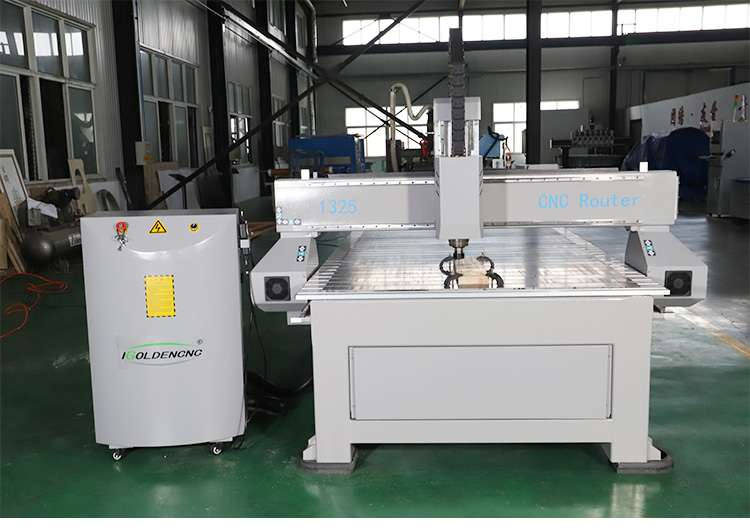

Factory actual shooting

A wood design machine can be various in types. We will briefly discuss them in the kind of CNC router section. In this part, we will have a glance at the working principle of the 3-axis CNC wood router machine.

The cutting tool has a motor that can move on the z-axis. It means the cutting tool can go up and down. On the other side, The cutting tool and the engine situated inside a box that can move only on Y-axis. At last, the total parts mentioned above can run along the X-axis. Consequently, we call this machine as a three-axis router.

Features of 2022 New wooden door design cnc router machine

• Aluminum plates (not cast aluminum) are adopted as the spindle subpanel, Z & X slide plate; they are precision-milled by CNC metal processing center. (If you are interested, please click here to check out how we did that). Shiny nice-looking, more importantly, their precision is exceptionally high. When compare with planner mill finished product, the accuracy is at least ten times higher.

• The electric spindle is an air-cooled one with a power of 3.5KW, 24,000RPM. It is capable of both carving and cutting applications. Easy operation, needn't connect water circulation system. You probably prefer a water cooling option; it's okay, please check this machine: cnc wood router 4x8 with water spindle

• Linear guides are critical to the accuracy and lifespan of a cnc wood router table machine. EagleTec uses original PMI rails and bearings (made in Taiwan) for W1325VC. Its lifespan is up to 8 to 10 years if using correctly. As the picture shows, PMI's product logo is visible on the rail.

• Individual control cabinet, most electronic components are installed in it. Cooling fans are installed on both sides of it to cool the electrical components, just like a computer.

• An interlock system is installed at the door of the electrical cabinet. This unit is a protective measure for the operator; It works this way, when locked, the machine power is on, and the cabinet door cannot be opened; When the door unlocked, the power is cut off. Therefore, if the operator wants to open the cabinet door, he needs to open the lock first. In this way, the power is cut off when the cabinet door is opened. It is to protect the operator from electric shock.

The assembly of the electrical part conforms with the CE standard seriously. Every cable has a unique wire mark, which is convenient for future fault diagnosis.

• A well-run lubrication system can significantly extend the lifespan of linear guides and bearings. This machine is equipped with a volumetric lubrication pump and dividers, which can evenly deliver lubricant to each bearing; the pipeline is unobstructed and will not block. Experienced users know that regular lubrication systems have two disadvantages. One is that the oil delivered is uneven, some are too much, and some are too little; another problem is that it is effortless to block.

T-slot and vacuum combo working platform design. Flexible use, it offers you two options on the way of workpiece clamping, vac-sorb or clamps.

Sample & Application

Applicable industies: Furniture, wood door, cabinet, MDF, Arts & Crafts, wood sculptures, 3D relief Business Signs, aluminum and other soft metals.