| Availability: | |

|---|---|

Four-Process CNC Cutting Machine Description:

The pneumatic 4 process cabinet cnc machine is a multi-function automatic CNC nesting machine, which integrates cutting, chamfering, relief, hollowing, punching, slotting and other processes, while meeting the processing requirements of cabinet doors and cabinets.

4 Processes CNC Router For Cabinet Features:

1.Pneumatic system cabinet cnc machine with ATC function is used for wood working factory. It can change tools automatically

2.Vacuum table using high-density material with great suction strength, comfortably accommadating all sizes of work piece.

3.NC studio control system is simple, convenient and easy to learn, users can quickly get the fleciblity to master the use of equipment, strong independence.

4.The frame adopts the gantry column structure, the machine parts are produced and assembled with extremely high precision to ensure the high performance and stability of the machine, excellent quality and tolerance.

Cabinet CNC Routers For Woodworking Machine Parameter Configuration :

Working Area | 1300*2500*200mm |

Spindle | HQD 4.5KW air cooling*2+6KW air cooling*2 |

Inverter | Fuling |

Motor | Servo motor |

Driver | Servo driver |

Control system | LNC system |

Working area | Vacuum absorbed table |

Guide rails | PEK |

Cabinet | Independent syntec |

Vacuum pump | 7.5KW water cooling pump |

Voltage | AC 380V-50HZ |

Weight | 2500KG |

The Advantages Of The 4 Processes CNC Router Cutting Machine:

1. Adopting advanced automatic tool change program, and program automatically executes machining requirements without manual intervention. Multiple spindles work at the same time, effectively improving machining efficiency.

2. Equipped with full absorption vacuum table, and the vacuum pump with strong adsorption force can strongly adsorb materials of different sizes, greatly improving work efficiency.

3. The machine bed is treated by a giant gantry and subjected to high temperature tempering to ensure small deformation, good rigidity, high strength, firmness and deformation, and durability.

4. Equipped with high-torque servo motor, high-precision gear and imported rack drive, which make the machine have the advantages of stable operation, low noise, high speed and high positioning accuracy.

5. Powerful vacuum system to ensure no dust flying during processing.

6. Adsorption system to ensure that in the process of processing does not lost the board to greatly improve the processing efficiency and avoid the waste of the board.

7. Oil filling system can automatically oil according to the time setting, to ensure the lubrication of the slider screw guide rail, extend the service life of the machine.

8. Intelligent control system, the control interface design is user-friendly, the operator does not need to train to operate.

9. With breakpoint memory, power-off continuous carving, processing time prediction and other functions, it is more smarter.

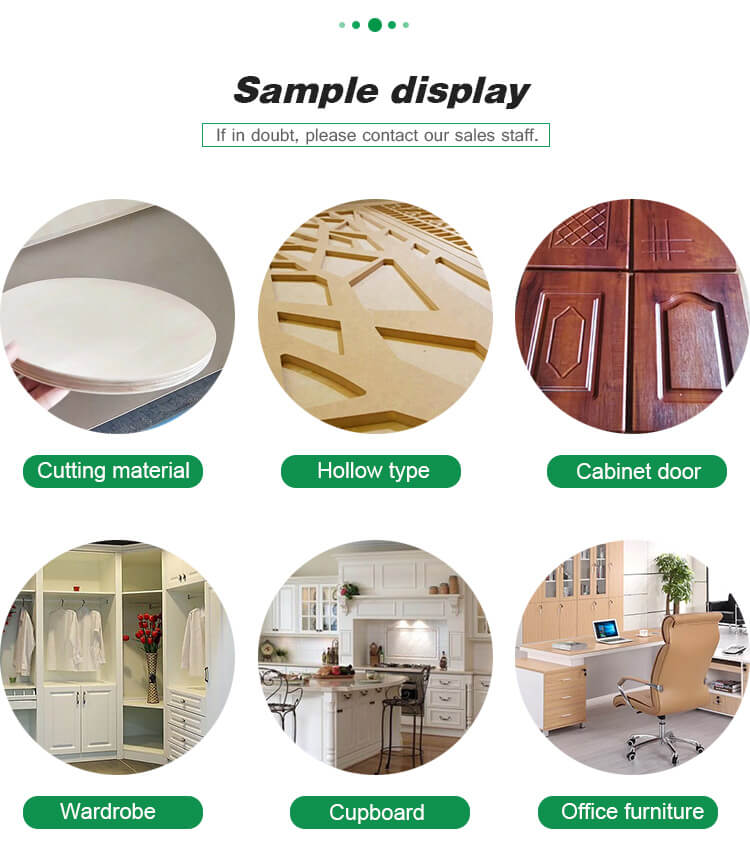

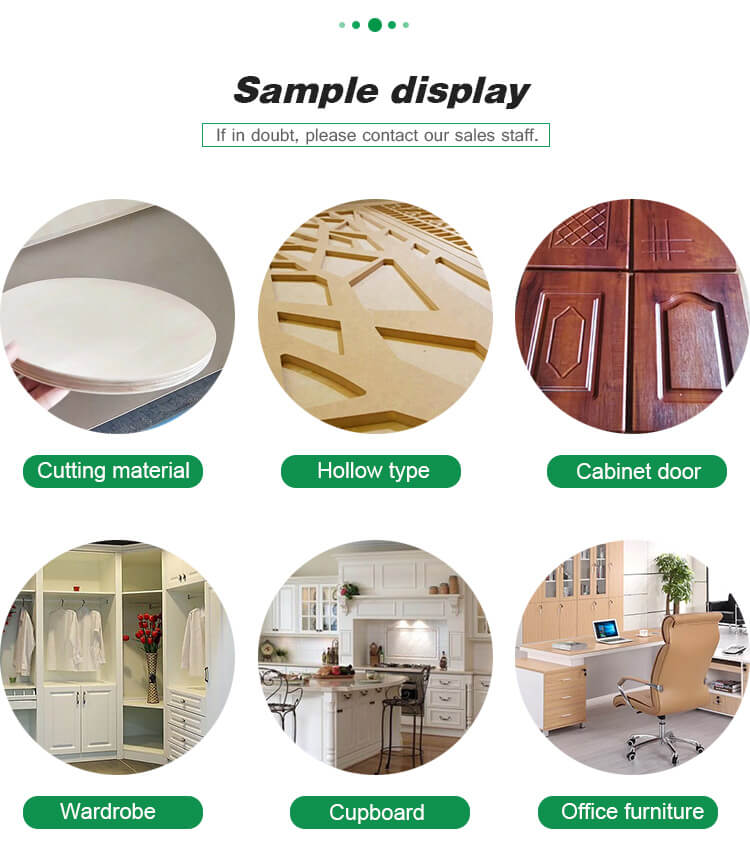

Four Process CNC Plywood Cutting Router Woodworking Machine Application:

1. Furniture: cabinet doors, solid wood doors, craft wooden doors, paint-free doors, screens, craft fan windows, tables, chairs, etc. Wooden door cutting, wooden door artwork carving, wave board, 3d photo carving, small or large relief works, cylindrical wood carving, 3d photo carving, etc.

2. Advertising industry: advertising signs and logos, decorative products, wood, medium density fiberboard, bamboo, plastic, PVC, acrylic, metal, stone, etc.

3. Art industry: character carving, character carving and cutting, famous brand making, small gift cutting, souvenir making, carving various decorative letters, small windows, fences, figures on walls, etc.

4. Model making: engraving metal molds such as copper, aluminum and iron, as well as non-metal molds such as marble, sandstone, plastic plates, PVC pipes and wood panels.

5. Other industries: CNC wood engraving machine can engrave all kinds of large reliefs and shadows, which are widely used in craft gift industry.

Shandong iGolden CNC Technology Co., Ltd. is a R&D,manufacturing,sales integration company that specializing in cnc router, laser engraving and cutting machine, plasma cutting machine, cutting plotter,etc.The main configuration all adopt top parts which imported from Italy, Japan,Germany,etc. And welcome to visit us for more choices.

FAQ:

1.What are the advantages of the four process cnc cutting machine?

This machine is economical and much cheaper than the automatic tool change machining center. In the case of no more than four processes, the tool change speed is also very fast and the efficiency is also very high. This equipment can be selected according to the needs of customers, including the economic model, the efficient model, the duplex model, and the automatic loading and unloading platform model (optional)

2.Is the four process cnc cutting machine suitable for processing cabinet door panel?

This machine is suitable for processing cabinet door panel, sliding door and other series of products, which can be processed in no more than four process shapes on the same panel.

3.How many sheets can the four process cnc cutting machine process according to eight hours a day?

Single station, four process economic model, according to eight hours per day processing, can complete 30-40 sheets. Single station, four process, high efficiency model, according to eight hours per day processing, can complete 50-60 sheets. Note: the number of plates processed above is calculated according to the cabinet process. The number of plates processed is different from the material, thickness, size and cutter of the plates processed by customers.

4.What is the difference between the four processes and the atc machining center?

Four processes can process cabinet door and cabinet body, but four processes and one process can only process four knives, and the machining center has 12 or 16 tool changes, which can process more complex door panels. If the customer considers that they will process more complex door panels in the future, it is suggested to use the processing center, which is the trend in the future.

5.What is the four process cnc cutting machine?

The four process CNC cutting machine is an economic and practical panel furniture cutting equipment, which has four processing spindles, pneumatic switching, and can install four different cutting tools, it can be used for panel furniture drilling, slotting, cabinet door milling and other technologies.

Four-Process CNC Cutting Machine Description:

The pneumatic 4 process cabinet cnc machine is a multi-function automatic CNC nesting machine, which integrates cutting, chamfering, relief, hollowing, punching, slotting and other processes, while meeting the processing requirements of cabinet doors and cabinets.

4 Processes CNC Router For Cabinet Features:

1.Pneumatic system cabinet cnc machine with ATC function is used for wood working factory. It can change tools automatically

2.Vacuum table using high-density material with great suction strength, comfortably accommadating all sizes of work piece.

3.NC studio control system is simple, convenient and easy to learn, users can quickly get the fleciblity to master the use of equipment, strong independence.

4.The frame adopts the gantry column structure, the machine parts are produced and assembled with extremely high precision to ensure the high performance and stability of the machine, excellent quality and tolerance.

Cabinet CNC Routers For Woodworking Machine Parameter Configuration :

Working Area | 1300*2500*200mm |

Spindle | HQD 4.5KW air cooling*2+6KW air cooling*2 |

Inverter | Fuling |

Motor | Servo motor |

Driver | Servo driver |

Control system | LNC system |

Working area | Vacuum absorbed table |

Guide rails | PEK |

Cabinet | Independent syntec |

Vacuum pump | 7.5KW water cooling pump |

Voltage | AC 380V-50HZ |

Weight | 2500KG |

The Advantages Of The 4 Processes CNC Router Cutting Machine:

1. Adopting advanced automatic tool change program, and program automatically executes machining requirements without manual intervention. Multiple spindles work at the same time, effectively improving machining efficiency.

2. Equipped with full absorption vacuum table, and the vacuum pump with strong adsorption force can strongly adsorb materials of different sizes, greatly improving work efficiency.

3. The machine bed is treated by a giant gantry and subjected to high temperature tempering to ensure small deformation, good rigidity, high strength, firmness and deformation, and durability.

4. Equipped with high-torque servo motor, high-precision gear and imported rack drive, which make the machine have the advantages of stable operation, low noise, high speed and high positioning accuracy.

5. Powerful vacuum system to ensure no dust flying during processing.

6. Adsorption system to ensure that in the process of processing does not lost the board to greatly improve the processing efficiency and avoid the waste of the board.

7. Oil filling system can automatically oil according to the time setting, to ensure the lubrication of the slider screw guide rail, extend the service life of the machine.

8. Intelligent control system, the control interface design is user-friendly, the operator does not need to train to operate.

9. With breakpoint memory, power-off continuous carving, processing time prediction and other functions, it is more smarter.

Four Process CNC Plywood Cutting Router Woodworking Machine Application:

1. Furniture: cabinet doors, solid wood doors, craft wooden doors, paint-free doors, screens, craft fan windows, tables, chairs, etc. Wooden door cutting, wooden door artwork carving, wave board, 3d photo carving, small or large relief works, cylindrical wood carving, 3d photo carving, etc.

2. Advertising industry: advertising signs and logos, decorative products, wood, medium density fiberboard, bamboo, plastic, PVC, acrylic, metal, stone, etc.

3. Art industry: character carving, character carving and cutting, famous brand making, small gift cutting, souvenir making, carving various decorative letters, small windows, fences, figures on walls, etc.

4. Model making: engraving metal molds such as copper, aluminum and iron, as well as non-metal molds such as marble, sandstone, plastic plates, PVC pipes and wood panels.

5. Other industries: CNC wood engraving machine can engrave all kinds of large reliefs and shadows, which are widely used in craft gift industry.

Shandong iGolden CNC Technology Co., Ltd. is a R&D,manufacturing,sales integration company that specializing in cnc router, laser engraving and cutting machine, plasma cutting machine, cutting plotter,etc.The main configuration all adopt top parts which imported from Italy, Japan,Germany,etc. And welcome to visit us for more choices.

FAQ:

1.What are the advantages of the four process cnc cutting machine?

This machine is economical and much cheaper than the automatic tool change machining center. In the case of no more than four processes, the tool change speed is also very fast and the efficiency is also very high. This equipment can be selected according to the needs of customers, including the economic model, the efficient model, the duplex model, and the automatic loading and unloading platform model (optional)

2.Is the four process cnc cutting machine suitable for processing cabinet door panel?

This machine is suitable for processing cabinet door panel, sliding door and other series of products, which can be processed in no more than four process shapes on the same panel.

3.How many sheets can the four process cnc cutting machine process according to eight hours a day?

Single station, four process economic model, according to eight hours per day processing, can complete 30-40 sheets. Single station, four process, high efficiency model, according to eight hours per day processing, can complete 50-60 sheets. Note: the number of plates processed above is calculated according to the cabinet process. The number of plates processed is different from the material, thickness, size and cutter of the plates processed by customers.

4.What is the difference between the four processes and the atc machining center?

Four processes can process cabinet door and cabinet body, but four processes and one process can only process four knives, and the machining center has 12 or 16 tool changes, which can process more complex door panels. If the customer considers that they will process more complex door panels in the future, it is suggested to use the processing center, which is the trend in the future.

5.What is the four process cnc cutting machine?

The four process CNC cutting machine is an economic and practical panel furniture cutting equipment, which has four processing spindles, pneumatic switching, and can install four different cutting tools, it can be used for panel furniture drilling, slotting, cabinet door milling and other technologies.

content is empty!