Views: 8 Author: Site Editor Publish Time: 2021-09-02 Origin: Site

The fiber laser cutting machine is mainly used in the metal processing industry. It adopts a fully automated production process to ensure high-efficiency operation in the production process and greatly reduce labor time costs. We can also customize according to customer requirements.

1. Adopting top world import fiber lasers, it has more stable performance and working hours can reach 100,000 hours.

2. It can save energy and protect the environment.

3. The photoelectric conversion rate is up to 25-30%. Low electric power consumption, it is only about 10% of traditional Pipes Fiber Laser Cutting Machine.

4. Adopting fiber optic cable transmission without mirrors, it can save maintenance costs.

Why need a Pipes Fiber Laser Cutting Machine for stainless steel?

fiber laser cutting machine is the best choice for Stainless steel cutting at high precision and efficiency.

CNC Router is able to complete some cutting or carving works of wood, plastic & soft metals(Aluminum, Copper, etc.), it can not cut or work on stainless steel.

fiber laser cutting machine cuts Stainless Steel(SS) better. If we want to cut metals such as stainless steel, there are 2 kinds of laser cutting machines as follows:

CO2 laser source with Oxygen (mainly for non-metal or metal cutting);

Fiber laser source (mainly for metal cutting and marking);

Fiber laser source has a higher efficiency work, if it is 1mm stainless steel or less than 3mm, we always recommend CNC Metal Laser Cutting Machine with a fiber

laser source.

fiber laser cutting machine application:

This fiber laser cutting machine is mainly used for cutting metal plates such as stainless steel,cabon steel,galvanized plate,various alloy,etc.

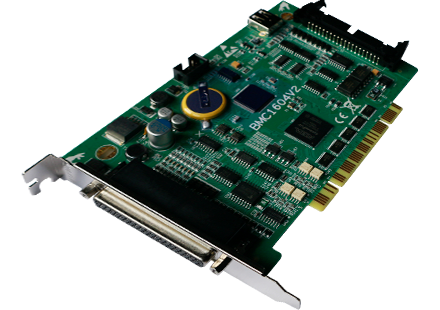

INTELLIGENT OPEN LOOP CONTROL SYSTEM

Cypcut laser cutting system is a full-featured open-loop control system launched specifically for the sheet metal processing industry.

✪ Support AI, DXF, PLT, Gerber, LXD and other graphic data formats, and accept international standard G codes.

✪ When opening and importing external files, optimization is automatically performed.

✪ Flexible and diverse automatic layout and manual layout sequence functions, a variety of array methods are available.

✪ The powerful material library function allows all process parameters to be saved for the same material to be used again.

✪ Processing breakpoint memory and positioning any point function.

✪ Fixed-height cutting, off-board following and multiple edge-finding methods.

✪ Support remote control of the system via wireless handheld box and Ethernet.

✪ One click to set flight cutting path.

✪ It is easy to install, easy to debug, excellent in performance and complete in plan.It is the fiber laser cutting control system with the highest market share at present.