Views: 8 Author: Site Editor Publish Time: 2022-07-21 Origin: Site

The plasma cnc cutting machine by improving technology and lower costs, market competition and so on, price also gradually reduced, the price can also accept small, medium and large firms, and in performance to meet the needs of the majority of enterprises. At present, along with national high and new technology development, plasma cutting Machine power prices have also been compared to previous years, has been under, cnc plasma tube cutting machine price is also lowered, I believe the future will be more widely applied .

Best cnc plasma cutting machine are used to achieve high cutting quality at low cost.Low cost Plasma Cutting Machinery – A very efficient and accurate solution as a cutting process – We can also arrange cut samples of different plasma processes and component shapes prior to arranging a demonstration of our plasma cnc cutting machine

• Fast: no preheating necessary, so the torch can start cutting instantly. With speeds up to 500IPM, it can rival laser cutters based on the type of part.

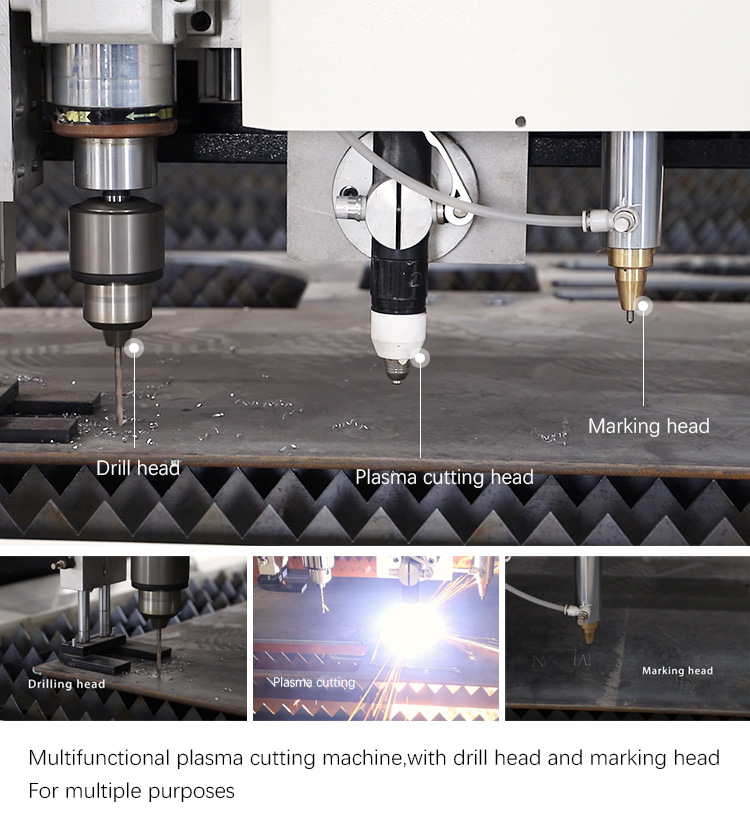

• Versatile: capable of piercing, complicated cutting and beveling in one process. Plasma cutters can successfully cut any electrically conductive metal up to 6" thick.

• Precise: paired with state of the art software and high accuracy components, the want for expensive secondary operations is eliminated. The torch head is computer controlled, making clean, sharp cuts.

• High Cut Quality: fewer dross and high superiority edges. Tight integration between the cutting torch and software results in high superiority manufacture.

• Easy to Use: while a CNC engine may seem complex, the CNC (computer numerically controlled) software takes most of the guess work out of cutting. With a state of the art package, even a first time worker is capable of creating wonderful outcome.

• Safe: most excellence systems offer an exhaust or down draft system to draw smoke away from the operator.

Disadvantages Of plasma cnc cutting machine

Can only cut through materials of about 1 inch

While a plasma cutter can cut through pretty much any metal that conducts electricity, in terms of thickness, it can only accommodate around 1 inch.

The cutting process is noisy

Although you are probably used to a little, or a lot, of noise in your workshop, you should know that plasma cutters tend to be loud. Plus, generate a lot of fumes, so you need to make sure your workspace is well ventilated.

Eye protection is needed

The electrical arc creates very bright flashes during the cutting process, so you need to make sure that every one of your workers are supplied with protective goggles and offered safety training.

Plasma cnc cutting machine Application

1.The Suitable material:

This cnc plasma cutting machine can work on Iron Plate, Aluminum sheet,Galvanized Sheet Stainless,Titanium plates etc. metal sheet and metal pipe can both cutting.

2.The application industries:

Cars, motorcycles, pressure vessels, chemical machinery, nuclear industry, general machinery, engineering machinery, steel structure, shipbuilding and other industries.