Views: 14 Author: Site Editor Publish Time: 2022-04-26 Origin: Site

Reverse the current situation of low efficiency, poor quality, high labor intensity, low material utilization, and the dirty environment in the thermal cutting industry. Narrow the gap with developed countries. At the same time, the development of plasma metal cutting machine can drive related fields and disciplines to reach the international advanced level.

The combustion is started by delivering cutting oxygen. Due to the increase in heat, the combustion continues rapidly in the adjacent workpiece. The moving torch cuts a slit. The burning molten material is blown away by the kinetic energy of the cutting oxygen jet. The following conditions must be completed when cutting:

(1) The ignition temperature of the material must be lower than its melting temperature.

(2) To exclude the generated metal oxide, the melting temperature of the oxide must be lower than the melting point of the material.

(3) Continuously maintain the ignition temperature at the cutting point. The heat loss is compensated by the heating flame. Both non-alloy plates of steel with a carbon content of less than 0.3% and low alloy steel with a carbon equivalent of more than 0.4% can be cut after preheating. As the proportion of metal elements increases, the cutting process will become more and more difficult. For this reason, materials such as chrome steel-nickel or silicon metal, cast steel, etc. Have no special precautions and are not suitable for oxygen cutting. These materials should be processed by other methods—a method for thermal cutting.

During the preheating process, the length of the preheating time can be increased or decreased according to the actual preheating situation. Similarly, the modified warm-up time will be memorized. The next warm-up will be preheated according to the modified warm-up time.

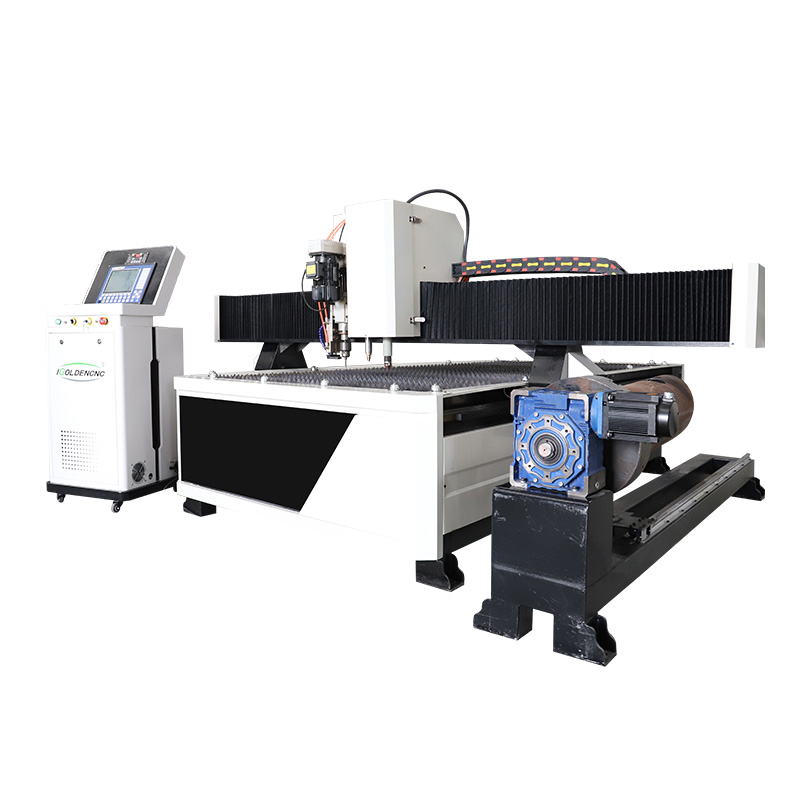

1. Thicker professional plasma metal cutting knife table

2. Water table , effective absorption of smoke than exhaust fan

3. Beijing Start controller with automatic height adjustment/ 4 axis tubes FL controller optional

4. Hypertherm, Thermadyne plasma power optional

5. SENKE adopt humanized control cabinet, more suitable for human really height

Advantages of plasma sheet metal cutting machine:

* High cutting technology.

* Minimum operating cost

* EDGE® Connect System (Hypertherm/USA)

* Arc Glide™ THC automatic height control system

* HyDefinition® technology

* PowerPierce™ technology

* LongLife™ technology

* HyPerformance® HPR-800XD® plasma source

* TurboNest® nesting software.

* The best choice for plasma with its high productivity and accurate cutting quality.

Igoldencnc manufacture the industry leading, ground-breaking plasma sheet metal cutting machine of our generation. Easily the most affordable machines of their standard on the market – incredibly simple software, highly-precise cutting and a quality, robust build that will let you cut all day long.