Views: 8 Author: Site Editor Publish Time: 2021-09-03 Origin: Site

CNC Plasma Cutting Machine with a rotary device is mainly for metal sheet cutting and tube cutting. The machine has been widely used for processing different kinds of metal materials, such as stainless steel, carbon steel, copper, aluminum, brass, galvanized sheet, and some others.

Plasma Cutter for Carbon refers to the cutting of metals using a plasma torch controlled from a computer. Plasma cutters operate by forcing a gas or compressed air at high speeds through a nozzle. Once an electric arc is introduced to the gas, ionized gas or plasma is created, the fourth state of matter. It, in turn, cuts through the metal.

CNC plasma cutting machine vary widely in size, price, and functionality. The machines are highly accurate and fast cutting through, slicing metals at speeds of up to 500 inches per minute. Plasma cutters require a plasma gas and an assist gas to function, and they vary according to the material being cut.

1) The beam uses light structural design,with good rigidity structure, light deadweight .

2) The gantry structure, Y axis used dual-motor dual-driven system,X,Y,Z axis all use dual-straight rail that make the machine driving smoothly with high-precision.

3) Aiming at cutting three dimension LED character, trough metal panels and floor cutting, the accuracy can reach good indicators.If it equipped with United States HYPERTHERM plasma source the machine can reach threshold.

4) Equipped with other advertise equipment (blister/engraving machine) .Improve the efficiency of several times

5) Cutting mouth is small, tidy,and avoid a second dressing processing.

What to do before repairing CNC plasma cutting machine?

1. DISCONNECT POWER

Make sure all the power is turned off, and the different gas flows are secured.

2. DISCHARGE CAPACITORS

There are extremely high voltages and currents inside a plasma cutter, so also make sure all the capacitors are discharged.

3. FORESEE AMPLE WORK SPACE

Ensure you have ample working space around the machine. Make sure you are to work in a safe way (e.g. not in the path of passing forklifts). If possible effect repairs outside of production hours.

4. FORESEE A WORK BENCH

Foresee a large and clean surface to place any components, bolts or tools.

5. WEAR SAFETY GEAR

Wear adequate protective gear such as a safety helmet, glasses and gloves.

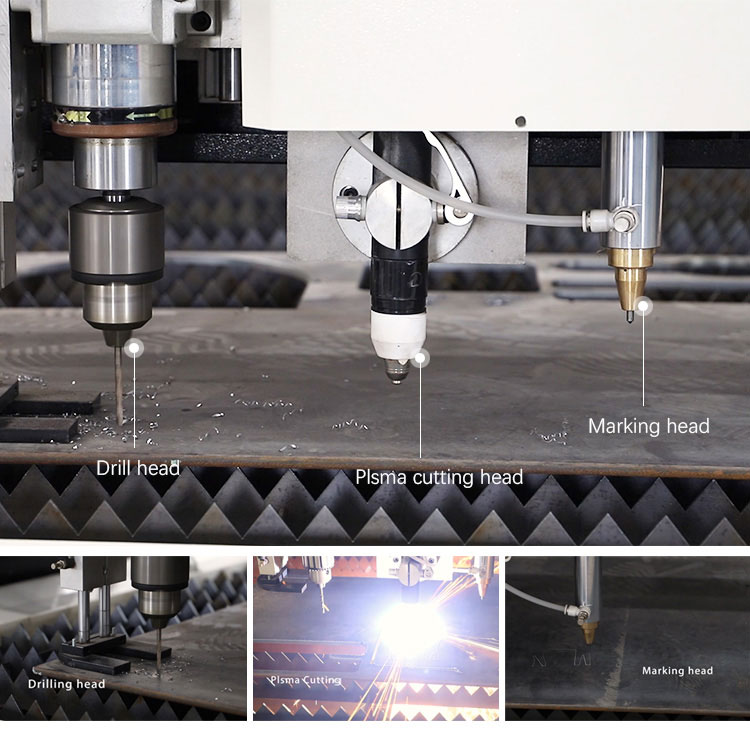

IGP-1530 Muti-function Plasma machine details

Applications of CNC plasma cutting machine?:

Advertising industry, arts and handicrafts cutting, kinds of metallic materials, such as Carbon Steel, Stainless steel, alloy steel, spring steel, copper plate, aluminium plate, gold, silver, Titanium and other metal plate and tube.

Motor and Driver

Famous brand motor and driver, excellent performance, stable and reliable quality. Using Japanese new design, new technology and high-quality materials, it has greater torque, lower heat generation, low vibration, smooth operation, and good anti-interference ability.