iGOLDEN

| Availability: | |

|---|---|

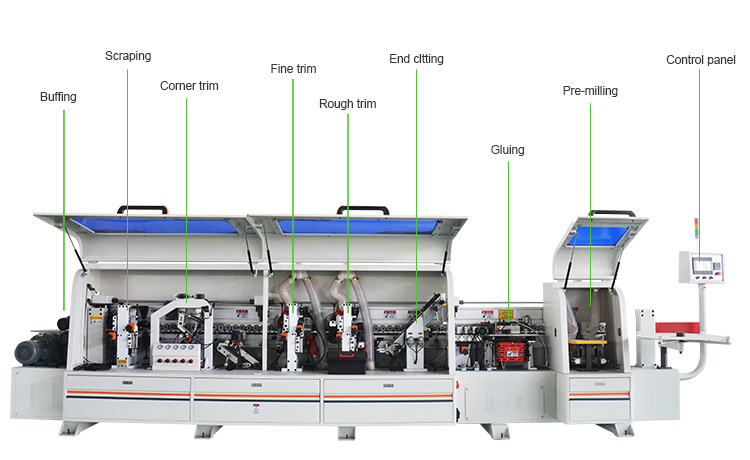

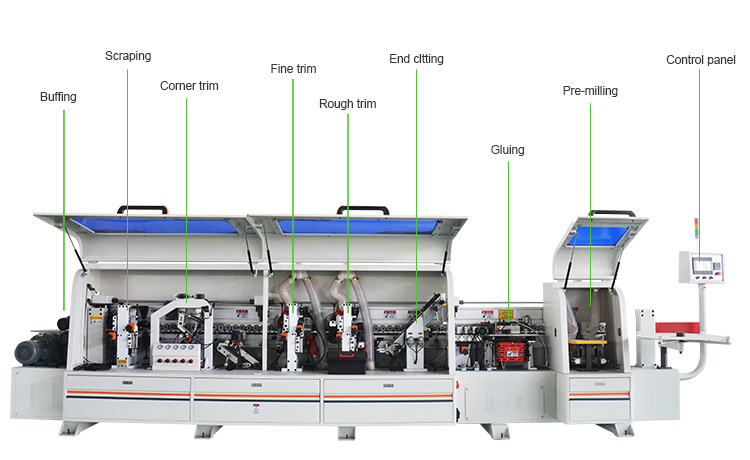

Description Of CNC Automatic Edge Banding Machine:

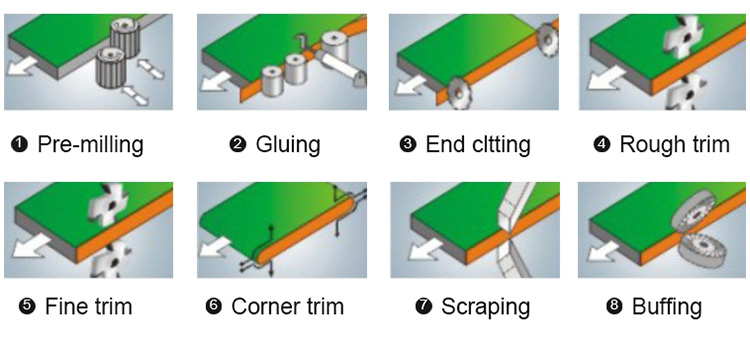

The CNC automatic edge banding machine is a highly automated machine that replaces the manual edge banding procedures (loose, pre-milling, glueing, cutting, flushing, rough trimming, fine trimming, scraping, polishing, grooving, profiling tracking) machine. The edge banding process is a very important process in the manufacturing process of panel furniture.

CNC Wood Edge Banding Machine Features:

1.Full-automatic edge banding machine function include glue,head together,rough repair,refine,Scraping edgeand polishing.

2.Have good shape,reasonable layout,has sound arrester,dust collector and overload protection.

3.The main parts of the machine adopt steel plate by laser cutting,one time welded together,the body is firm and undeformed.

4.Can increase or decrease component structure according to actual demand.

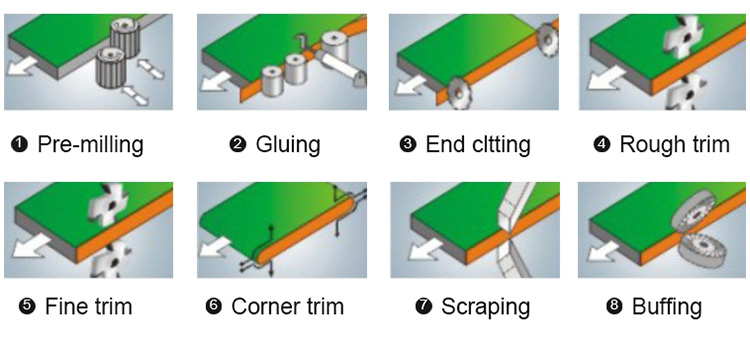

The Function Of Automatic Edge Banding Machine:

This is a fully automatic edge banding machine. It has the characteristics of delicate and smooth edge banding, good hand feeling, straight and smooth sealing line, and so on. And it is very suitable for the production and use of large and medium-sized furniture, cabinets and other panel furniture.

Pre-milling-gluing-front-to-back flushing-roughing up and down-finishing up and down-anti-tracking front and back-scraping up and down-polishing up and down

Advantages Of CNC Automatic Edge Banding Machine:

1. Trim equipment with double trim-blades works on the waved effect that is caused by precise dimersicen saw.

2. The glue mechanism adopt a special structure to gelatinize the plates and coating materials uniformly, ensure a more solid conglutination.

3. End-trimming mechanism through a precise guide track movement, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the cutting surface smoothly.

4. Rough/fine trimming mechanism used for repairing the excess edge materials, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the trimming plates smoothly.

5. Profiling unit, to make board end smooth and aesthetic.

Specification of CNC Wood Edge Banding Machine:

Panel length | ≥120mm |

Panel width | ≥60mm |

Panel thickness | 10-60mm |

Edge band width | 12-65mm |

Edge band thickness | 0.4-3mm

|

Feed speed | 12/16/20m/min |

Input Voltage | 380V |

Input frequency | 50HZ |

Output frequency | 200HZ |

Total power | 8.23KW |

Air pressure | 6kg/cm2 |

Machine size | 6585*970*1520mm |

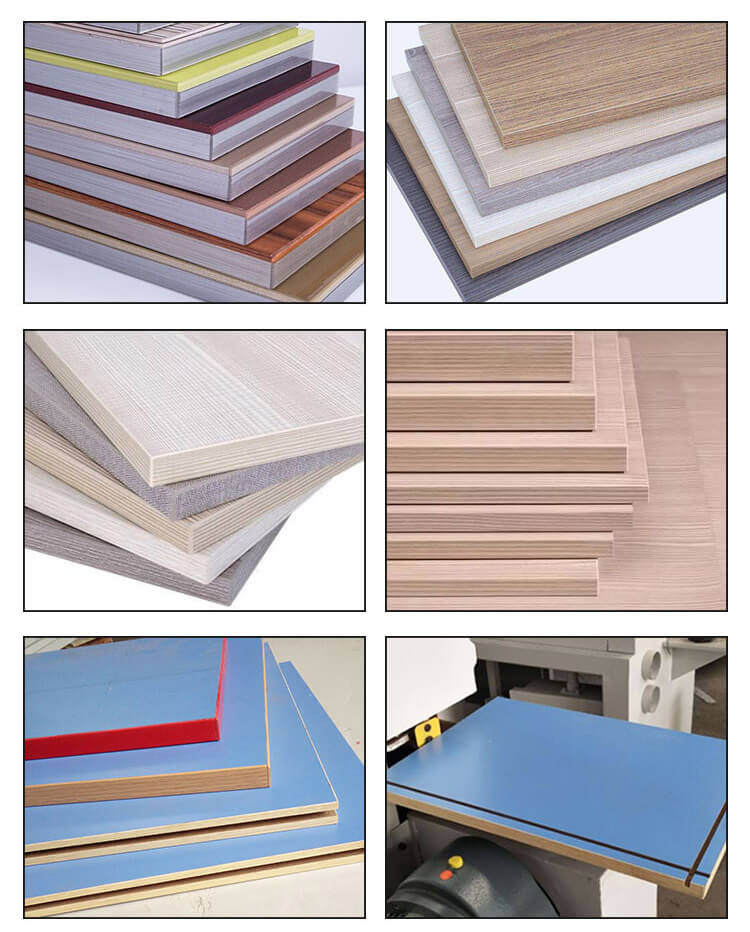

Application Of Automatic Edge-Banding Machine:

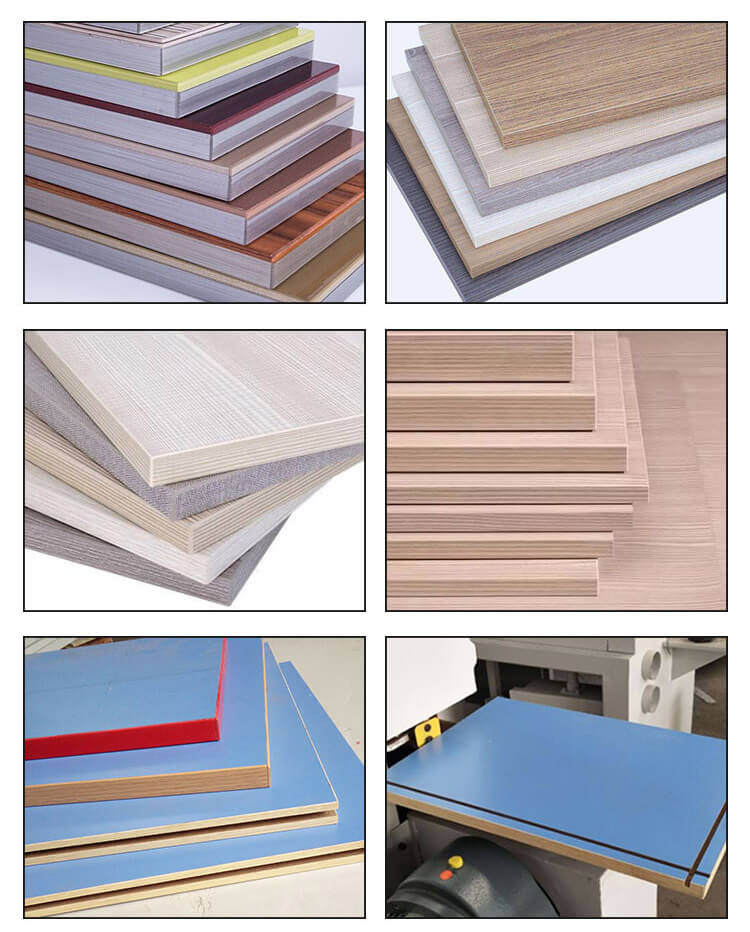

This machine is suitable for the straight plane edge sealing of MDF, particleboard, woodworking mesh board, solid wood board, etc. The sealing material can be ABS, PVC, veneer, wood strip, or melamine.

It is suitable for straight edge sealing of solid wood board, fiberboard, particleboard and other sheet metal parts. The edge sealing material can be made of solid wood strip, PVC, melamine, thin veneer, etc.

Shandong iGolden CNC Technology Co., Ltd. is a R&D,manufacturing,sales integration company that specializing in cnc router, laser engraving and cutting machine, plasma cutting machine, cutting plotter,etc.The main configuration all adopt top parts which imported from Italy, Japan,Germany,etc. And welcome to visit us for more choices.

FAQ:

1. How much is the edge banding machine?

Are you mainly engaged in panel furniture business? For edge banding machine, the price is different according to the function and configuration. If you are mainly used for the cabinet, we can recommend you to consider the full-automatic double trimming edge banding machine. Do you know all the functions of edge banding machine?

2. What is the function of the copy tracking function?

The plate drives the profiling wheel to follow the shape of the workpiece through the driving mechanism to polish and trim it into an R arc to improve the aesthetic effect, and also make the edge banding belt closely fit the workpiece, ensure the quality of the final edge.

3.Where is the edge banding machine made?

Our edge banding machine is made in Guangdong Province. We mainly make numerical control equipment. In order to make customers more worry free in training and after-sales, therefore, we can purchase the edge banding machine for you, and also guarantee to maintain the reputation and quality of our company. It will be more cautious and serious for us to choose the manufacturer of edge banding machine. Brand companies can be trusted.

Description Of CNC Automatic Edge Banding Machine:

The CNC automatic edge banding machine is a highly automated machine that replaces the manual edge banding procedures (loose, pre-milling, glueing, cutting, flushing, rough trimming, fine trimming, scraping, polishing, grooving, profiling tracking) machine. The edge banding process is a very important process in the manufacturing process of panel furniture.

CNC Wood Edge Banding Machine Features:

1.Full-automatic edge banding machine function include glue,head together,rough repair,refine,Scraping edgeand polishing.

2.Have good shape,reasonable layout,has sound arrester,dust collector and overload protection.

3.The main parts of the machine adopt steel plate by laser cutting,one time welded together,the body is firm and undeformed.

4.Can increase or decrease component structure according to actual demand.

The Function Of Automatic Edge Banding Machine:

This is a fully automatic edge banding machine. It has the characteristics of delicate and smooth edge banding, good hand feeling, straight and smooth sealing line, and so on. And it is very suitable for the production and use of large and medium-sized furniture, cabinets and other panel furniture.

Pre-milling-gluing-front-to-back flushing-roughing up and down-finishing up and down-anti-tracking front and back-scraping up and down-polishing up and down

Advantages Of CNC Automatic Edge Banding Machine:

1. Trim equipment with double trim-blades works on the waved effect that is caused by precise dimersicen saw.

2. The glue mechanism adopt a special structure to gelatinize the plates and coating materials uniformly, ensure a more solid conglutination.

3. End-trimming mechanism through a precise guide track movement, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the cutting surface smoothly.

4. Rough/fine trimming mechanism used for repairing the excess edge materials, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the trimming plates smoothly.

5. Profiling unit, to make board end smooth and aesthetic.

Specification of CNC Wood Edge Banding Machine:

Panel length | ≥120mm |

Panel width | ≥60mm |

Panel thickness | 10-60mm |

Edge band width | 12-65mm |

Edge band thickness | 0.4-3mm

|

Feed speed | 12/16/20m/min |

Input Voltage | 380V |

Input frequency | 50HZ |

Output frequency | 200HZ |

Total power | 8.23KW |

Air pressure | 6kg/cm2 |

Machine size | 6585*970*1520mm |

Application Of Automatic Edge-Banding Machine:

This machine is suitable for the straight plane edge sealing of MDF, particleboard, woodworking mesh board, solid wood board, etc. The sealing material can be ABS, PVC, veneer, wood strip, or melamine.

It is suitable for straight edge sealing of solid wood board, fiberboard, particleboard and other sheet metal parts. The edge sealing material can be made of solid wood strip, PVC, melamine, thin veneer, etc.

Shandong iGolden CNC Technology Co., Ltd. is a R&D,manufacturing,sales integration company that specializing in cnc router, laser engraving and cutting machine, plasma cutting machine, cutting plotter,etc.The main configuration all adopt top parts which imported from Italy, Japan,Germany,etc. And welcome to visit us for more choices.

FAQ:

1. How much is the edge banding machine?

Are you mainly engaged in panel furniture business? For edge banding machine, the price is different according to the function and configuration. If you are mainly used for the cabinet, we can recommend you to consider the full-automatic double trimming edge banding machine. Do you know all the functions of edge banding machine?

2. What is the function of the copy tracking function?

The plate drives the profiling wheel to follow the shape of the workpiece through the driving mechanism to polish and trim it into an R arc to improve the aesthetic effect, and also make the edge banding belt closely fit the workpiece, ensure the quality of the final edge.

3.Where is the edge banding machine made?

Our edge banding machine is made in Guangdong Province. We mainly make numerical control equipment. In order to make customers more worry free in training and after-sales, therefore, we can purchase the edge banding machine for you, and also guarantee to maintain the reputation and quality of our company. It will be more cautious and serious for us to choose the manufacturer of edge banding machine. Brand companies can be trusted.

content is empty!