iGC-B

iGOLDENCNC

| Availability: | |

|---|---|

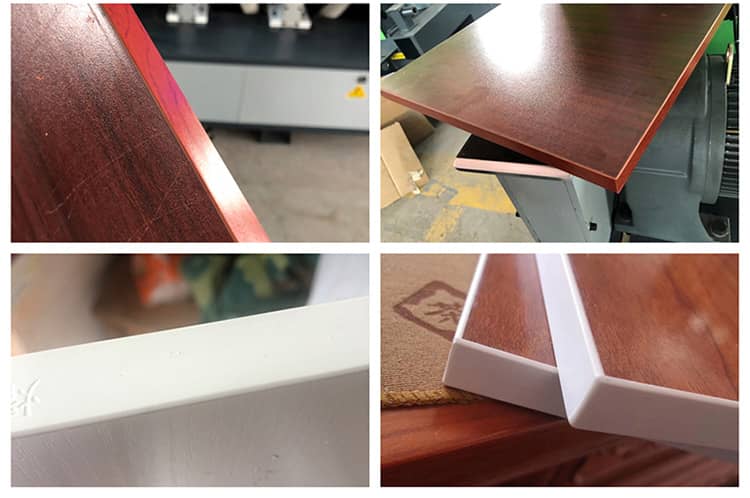

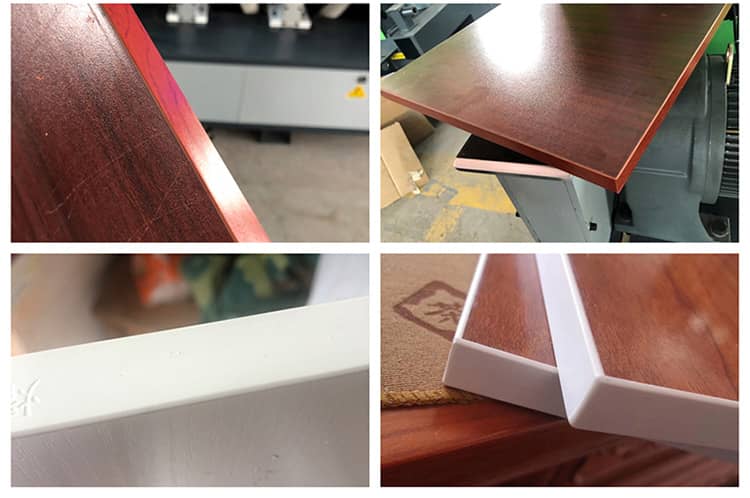

This wood edge machine of IGOLDENCNC can bring you perfect results of high-quality workpieces As a cost-effective fully automatic edge banding machine, it can complete gluing, banding, edge cutting, rough trimming, fine trimming, tracking, scraping and polishing functions automatically. It is widely used for banding various wooden boards, such as density boards, fiber boards, particle boards, solid wood panels, etc.

The wood edge banding machine is stable, reliable and durable, and the price is affordable. It is especially designed for furniture and cabinet manufacturers.

plywood edge banding machine, with functions of bonding and pressing, flushing, chamfering, rough trimming, fine trimming, scraping, polishing, and additionally, pre-milling, corner rounding, tracking, and grooving can be added upon request.

Plywood edge banding machine Features

1) This edge bander is ideal for building an automatic production line. Stability and controlled ability are the most important

factors for an equipment to be part of production line.

2) The glue mechanism adopts a special structure to gelatinize the plates and coating materials uniformly, ensure a more solid conglutination.

3) End-trimming mechanism through a precise guide track movement, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the cutting surface smoothly.

4) Rough &Fine Trimming unit, with two individual high frequency motors, trim the exceeding edge on the top and bottom side of the panel, ensure the top and bottom side of the edge smooth and even.

5) Scraping unit for a perfect finishing of the applied edge.

6)The buffing device adopt the board processed by cotton polishing wheel, by end-polishing to make a more smooth surface.

7)Grooving is a optional function for edge banding machine. It's used to slot out one groove on panel to install glass, back panel etc

8) Scraping unit for a perfect finishing of the applied edge.

Application

The wood edge machine is suitable for such plates: MDF, block board, solid wood board, particleboard, polymer door plates, plywood etc, straight line edging and trimming.

We will provide a manual with simple troubleshooting of the machine, which will help you deal with common problems on the machine.

We will provide a lot of technical support and after-sale service online, just like detailed technical and installation instructions. For example, when you encounter a maintenance problem, we will make a complete and detailed video of the operation process based on the problem, it seems that I am on your side to guide you on how to deal with the problem.

3-Fast spare parts and technical assistance

Our large amount of spare parts inventory means that replacement parts will be delivered to you as soon as you are in demand. Get technical help right away by email or phone.

4-Free training services

We insist on hands-on training for customers on each machine sold. The training is free and we will cooperate with you to ensure that you operate comfortably with your new machine.

We feel proud of our expertise and educational ability for installing, properly maintaining and most effectively using iGOLDENCNC machines.

5-Special design, customized, OEM order

iGOLDENCNC is willing to help you realize your special ideas and requirements with our innovative ability. Therefore, when you need specially designed or customized machines and OEM machines, please contact us immediately.

This wood edge machine of IGOLDENCNC can bring you perfect results of high-quality workpieces As a cost-effective fully automatic edge banding machine, it can complete gluing, banding, edge cutting, rough trimming, fine trimming, tracking, scraping and polishing functions automatically. It is widely used for banding various wooden boards, such as density boards, fiber boards, particle boards, solid wood panels, etc.

The wood edge banding machine is stable, reliable and durable, and the price is affordable. It is especially designed for furniture and cabinet manufacturers.

plywood edge banding machine, with functions of bonding and pressing, flushing, chamfering, rough trimming, fine trimming, scraping, polishing, and additionally, pre-milling, corner rounding, tracking, and grooving can be added upon request.

Plywood edge banding machine Features

1) This edge bander is ideal for building an automatic production line. Stability and controlled ability are the most important

factors for an equipment to be part of production line.

2) The glue mechanism adopts a special structure to gelatinize the plates and coating materials uniformly, ensure a more solid conglutination.

3) End-trimming mechanism through a precise guide track movement, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the cutting surface smoothly.

4) Rough &Fine Trimming unit, with two individual high frequency motors, trim the exceeding edge on the top and bottom side of the panel, ensure the top and bottom side of the edge smooth and even.

5) Scraping unit for a perfect finishing of the applied edge.

6)The buffing device adopt the board processed by cotton polishing wheel, by end-polishing to make a more smooth surface.

7)Grooving is a optional function for edge banding machine. It's used to slot out one groove on panel to install glass, back panel etc

8) Scraping unit for a perfect finishing of the applied edge.

Application

The wood edge machine is suitable for such plates: MDF, block board, solid wood board, particleboard, polymer door plates, plywood etc, straight line edging and trimming.

We will provide a manual with simple troubleshooting of the machine, which will help you deal with common problems on the machine.

We will provide a lot of technical support and after-sale service online, just like detailed technical and installation instructions. For example, when you encounter a maintenance problem, we will make a complete and detailed video of the operation process based on the problem, it seems that I am on your side to guide you on how to deal with the problem.

3-Fast spare parts and technical assistance

Our large amount of spare parts inventory means that replacement parts will be delivered to you as soon as you are in demand. Get technical help right away by email or phone.

4-Free training services

We insist on hands-on training for customers on each machine sold. The training is free and we will cooperate with you to ensure that you operate comfortably with your new machine.

We feel proud of our expertise and educational ability for installing, properly maintaining and most effectively using iGOLDENCNC machines.

5-Special design, customized, OEM order

iGOLDENCNC is willing to help you realize your special ideas and requirements with our innovative ability. Therefore, when you need specially designed or customized machines and OEM machines, please contact us immediately.