| Availability: | |

|---|---|

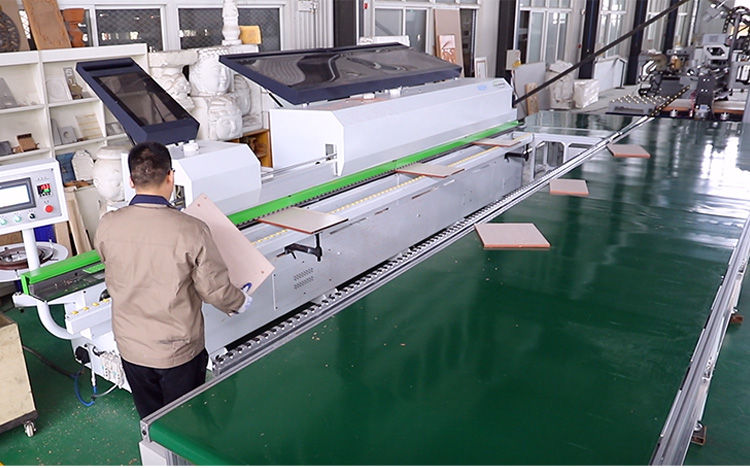

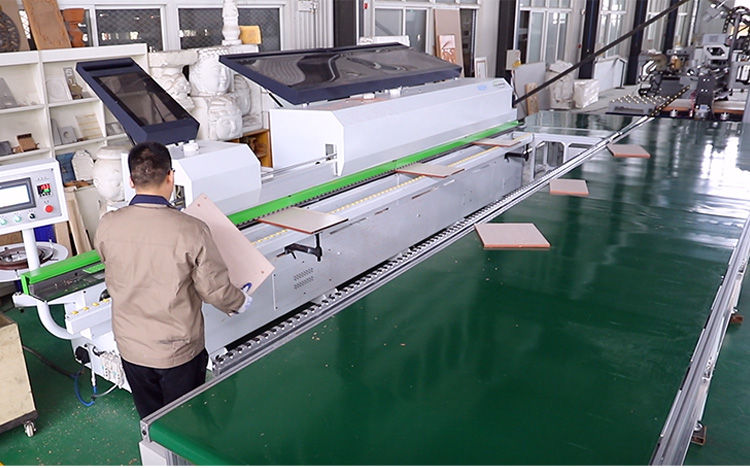

Automatic Cabinet CNC Edgebanding Machine:

| DEITA PLC control system The independent LCD screen has a touch screen speed control function, and you can see the operation process of the machine more clearly, real-time monitoring, real-time adjustment, and more precise. |

| Pre-milling When the edge-sealing surface of the plate is not flat, it can be milled first and then glued and pressed. |

| Gluing Non-sticky pot, uniform sol, cylinder control pressure roller, better tape effect. |

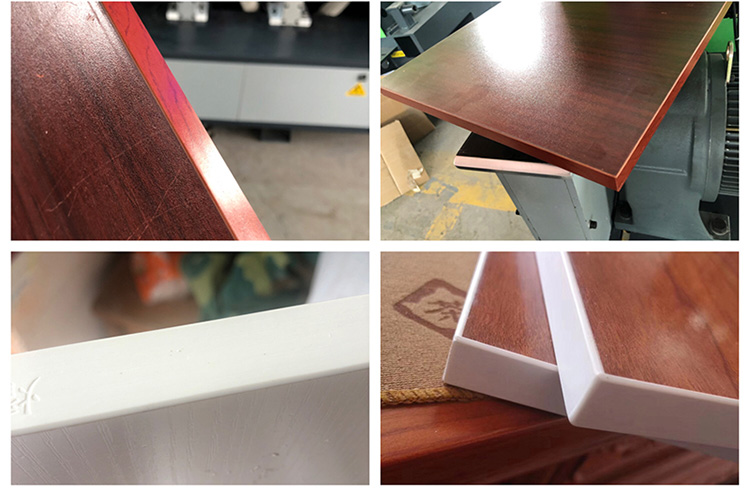

| End cutting Through the structure of automatic profiling and high-frequency high-speed motor, the redundant edge bands before and after are cut off to ensure a smooth and smooth section. |

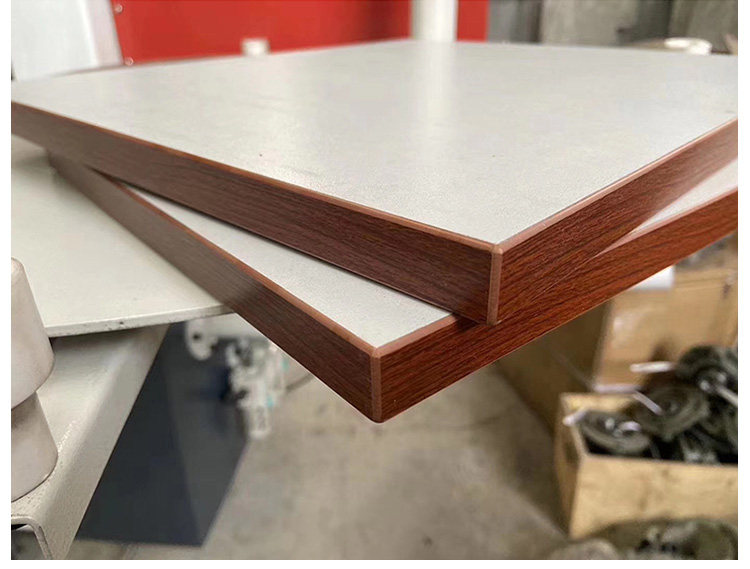

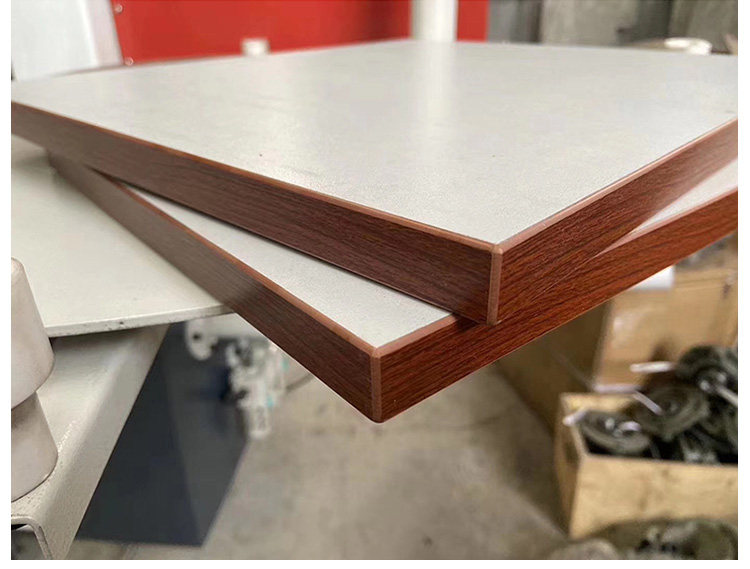

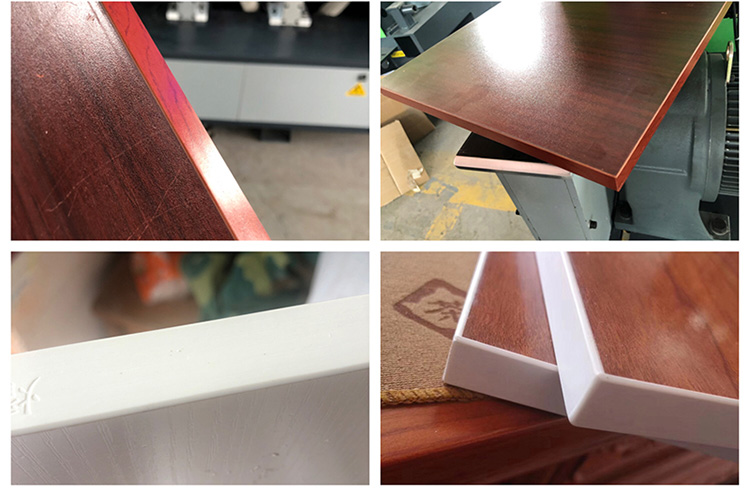

| Rough trim and Fine trim which is used to trim the excess edge banding material on the upper and lower parts of the processed sheet edge band, so that the upper and lower parts of the trimmed sheet are smooth and smooth. |

| Corner trim The chamfering effect is repaired, and the edge banding effect is more round and smooth. |

| Scraping It is used to eliminate the ripple marks caused by the non-linear motion cutting process of the trimming. |

| Buffing Use a cotton polishing wheel to clean the polished plate to remove excess glue and make it smoother. |

Revolving line

The addition of the rotary line can greatly save time and improve the production line rate.

Babinet Edge Banding Machine Scope of Application:

This machine is suitable for linear edge banding and edge banding materials of solid wood board, fiberboard, particle board and other plate workpieces.

Available solid wood strips, pvc, melamine, veneer strips, etc.

Automatic Cabinet CNC Edgebanding Machine:

| DEITA PLC control system The independent LCD screen has a touch screen speed control function, and you can see the operation process of the machine more clearly, real-time monitoring, real-time adjustment, and more precise. |

| Pre-milling When the edge-sealing surface of the plate is not flat, it can be milled first and then glued and pressed. |

| Gluing Non-sticky pot, uniform sol, cylinder control pressure roller, better tape effect. |

| End cutting Through the structure of automatic profiling and high-frequency high-speed motor, the redundant edge bands before and after are cut off to ensure a smooth and smooth section. |

| Rough trim and Fine trim which is used to trim the excess edge banding material on the upper and lower parts of the processed sheet edge band, so that the upper and lower parts of the trimmed sheet are smooth and smooth. |

| Corner trim The chamfering effect is repaired, and the edge banding effect is more round and smooth. |

| Scraping It is used to eliminate the ripple marks caused by the non-linear motion cutting process of the trimming. |

| Buffing Use a cotton polishing wheel to clean the polished plate to remove excess glue and make it smoother. |

Revolving line

The addition of the rotary line can greatly save time and improve the production line rate.

Babinet Edge Banding Machine Scope of Application:

This machine is suitable for linear edge banding and edge banding materials of solid wood board, fiberboard, particle board and other plate workpieces.

Available solid wood strips, pvc, melamine, veneer strips, etc.

content is empty!