Views: 33 Author: Site Editor Publish Time: 2021-11-03 Origin: Site

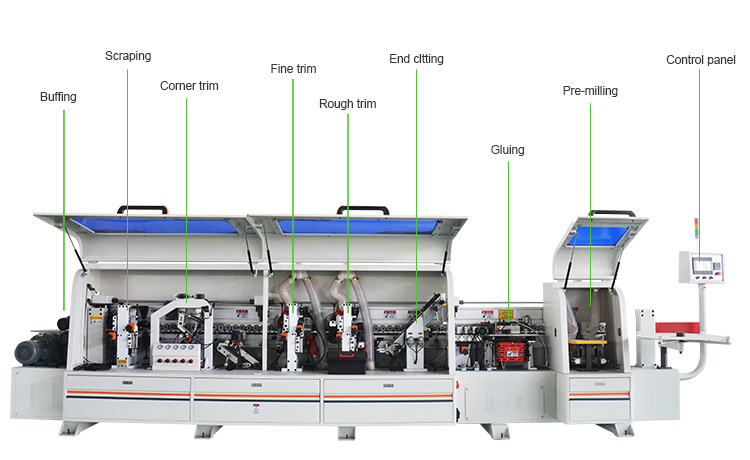

The automatic edge banding machine is a highly automated machine that replaces the manual edge banding procedures (loose, pre-milling, glueing, cutting, flushing, rough trimming, fine trimming, scraping, polishing, grooving, profiling tracking) machine. The edge banding process is a very important process in the manufacturing process of panel furniture.

What are the functions of the automatic edge banding machine?

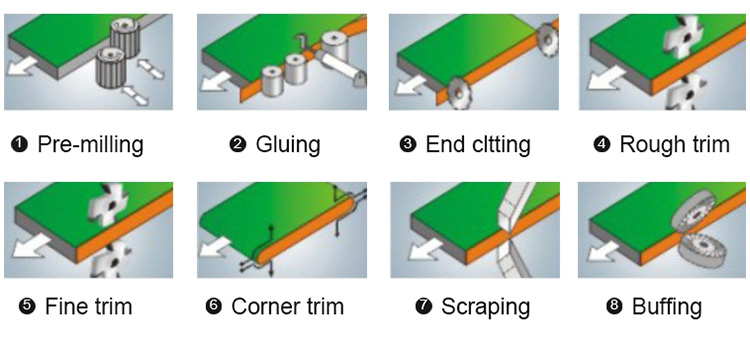

Pre-milling: Double milling cutters are used to modify the ripple marks, burrs or non-vertical phenomenon caused by the panel saw processing to achieve better edge sealing effect and to make the edge band and the board more tightly fit, better integrity and aesthetics.

Adhesive edge banding: Adopting a special structure, evenly apply adhesive on both sides of the edge banding plate and edge banding material to ensure a stronger adhesion.

Head-to-head: through precise linear guide rail movement, adopts automatic tracking of the mold and high-frequency high-speed motor fast cutting structure to ensure the cut surface is smooth and smooth.

Finishing: Both the profile automatic tracking and high-frequency high-speed motor structure are used to ensure the smoothness of the upper and lower parts of the trimmed board. It is used to repair excess edge banding material above and below the edge band of the plate. The finishing knife is an R-shaped knife. It is mainly used for PVC and acrylic edge banding for panel furniture. Edge banding with thickness of 0.8 mm or more is preferred.

Scraping: Used to eliminate the ripple marks caused by the non-linear motion of the trimming process, so that the upper and lower parts of the board are smoother and cleaner.

Scraping: Used to eliminate the ripple marks caused by the non-linear motion of the trimming process, so that the upper and lower parts of the board are smoother and cleaner.

Polishing: Clean the processed sheet with a cotton polishing wheel, and make the edge sealing end surface smoother by polishing.

Slotting: It is used for direct slotting of wardrobe side panels, bottom plates, etc., reducing the process of panel sawing, and it is more convenient and fast. It can also be used for slotting of aluminum edging of door panels.

Advantage of automatic edge banding machine:

1. Adopt imported motor and high quality electrical component.

2. Product serialization and diversification is easy for the customer to choose.

3. High precision and work efficiency.

4. Automatic and precise gluing procedure as well as integrated double finish.

5. High strength frame structure, durable

6. Glue evenly, conveying stability

7. The machine is equipped with hand lubricator to reduce wear

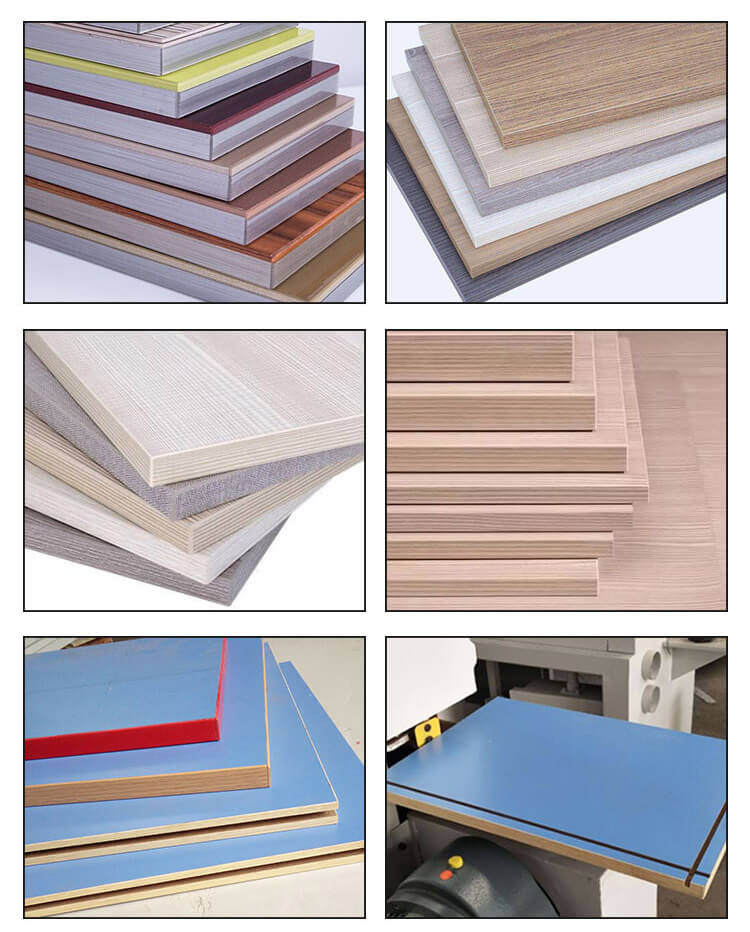

Automatic edge banding machine application:

The Edge Banding Machine mainly includes the fuselage, each processing group and the control system. The processing components mainly include: pre-milling, gluing, edge-sealing, aligning, roughing, finishing, contouring, scraping, polishing, and slotting. Mainly used for edge sealing of panel furniture. It is characterized by automation, high efficiency, high precision and aesthetics. It has been widely used in domestic panel furniture manufacturers.

First, the automatic edge banding machine The most important part related to the accuracy is the upper and lower beams, because it is related to whether the processing plates can run in a straight line to ensure that each processing group can work accurately. Mainly divided into two types of beams: First: aluminum alloy material, one-time casting, second: cast iron beam.

Among them, aluminum alloy beams are a more advanced way, because precision and straightness are far superior to cast iron.

Second, the key part of the fuselage, the fuselage base. The more advanced way is the laser cutting of the steel plate, one welding. The advantage is that the fuselage is firm and not deformed, thus increasing the stability of the whole machine. The more backward way is the skeleton welding And then supplement the steel plate, the disadvantage is that the stability is relatively poor, the advantage is the low price.

Third, the major manufacturers of CNC modules can be independently designed, most of them have applied for patent protection, and the feed rate has reached the advanced level in foreign countries. Today's more advanced PLCs include the LG series, the Siemens series and more.

Fourth, the structure of each ministry is basically similar. The corresponding group can be added or reduced according to the actual processing needs. Among them, the technical tracking of the profiling is the most difficult. Although the machining process guarantees the precision of the components, due to the precise control action of the PLC and the angle of the knife and the angle of the profiling, there are only a few large factories in China. More mature.