Views: 27 Author: igoldenCNC Publish Time: 2021-09-27 Origin: igoldencnc

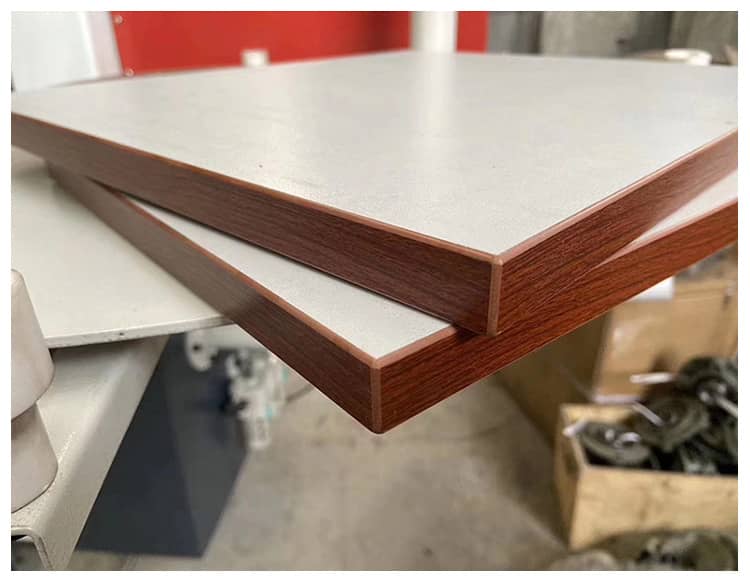

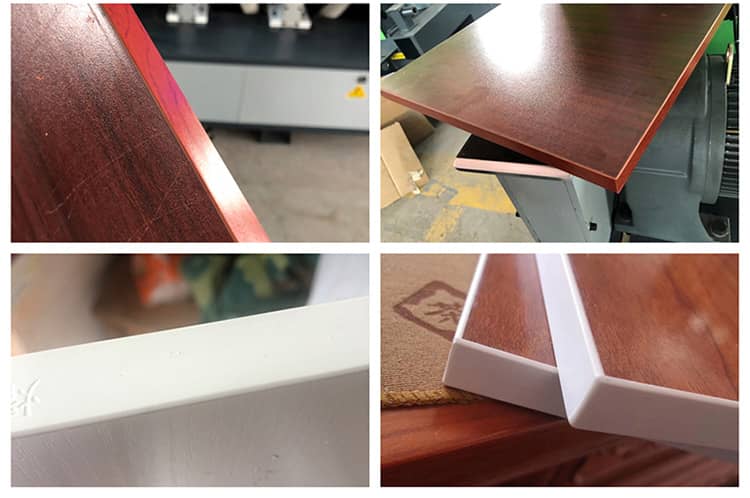

Edge banding machines and equipment with various options and accessories. Anyone who regularly glues edges ensures good results at all times with a professional edge banding machine. Our edge banding machines are particularly suitable for gluing solid wood edges, veneer edges as well as plastic edges and are optionally available with or without corner rounding function.

An edge banding machine is a woodworking machine used to apply a thin strip of material, called an edge band, to the exposed edges of a sheet of wood-based panel such as plywood, particle board or MDF. The edge banding can be made of a variety of materials, such as PVC, ABS, wood veneer, or melamine.

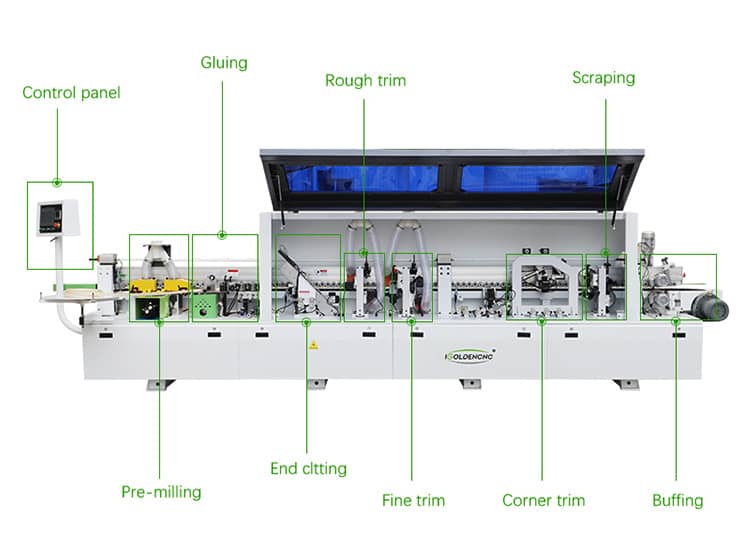

The machine typically consists of a feed roller, glueing unit, pressure rollers, trimming unit, and a buffing unit. The sheet of wood-based panel is fed into the machine, where the edge band is applied to the exposed edge of the sheet. The glue is applied to the edge band using a glue roller, and the edge band is then pressed onto the panel using pressure rollers. The excess edge band is trimmed using a cutting unit, and the edge is then buffed to achieve a smooth finish.

Edge banding machine are commonly used in the furniture industry to produce a variety of products, such as cabinets, shelves, and tables. They can be operated manually or automatically, and some machines are equipped with advanced features such as automatic thickness adjustment, automatic edge feed, and digital controls.

8 different models to meet every requirement

From manual adjustment to full automation

Intuitive operation – innovative powerTouch control system

Highly flexible configuration

Features of edge banding machine wood

Flexible glue application system for easy changing of the color and glue type (EVA, PUR)

Multifunctional profile trimming unit for corner rounding and flush trimming

Short setup times thanks to pneumatic adjustment of the units

Multi-stage technology for highly flexible use with changing materials

(As standard available at the edition-model)

Zero joints with airTec for optimum joint-free finish

(As standard available at the airTec-model)

1.Pre-milling system

Pre-milling adopts double linear guide, with higher guidance accuracy and good motion stability, pre-cutter Φ125mm H35mm six-tooth diamond pre-milling cutter, with high hardness and wear resistance, longer service life.

2. Gluing system

In gluing system, the glue box is coated with Teflon, which makes the box cleaning easier. The glue box has the temperature maintaining function and can shorten heating time and avoid the glue carbonization. The machine can use the high temperature EVA hot melt glue and can deliver the glue by spiral structure. The glue box size is 200*150*450mm.

3. Feeding and edge cutting system

When the single unit feeding system can be used to load the strip (optional) and roller type edge bands and the edge band thickness can be 0.4~3mm. If the single work unit can not meet the working requirements, the 2-10 feeding units can be selected. The edge cutting cylinder is controlled by double solenoid valves.

4. Press system

The precise large press wheel and glue wheel can work together to ensure the press effect. The small press wheel are composed of 2 upper and lower cone wheels and 1 straight wheel. The upper and lower cone wheels can ensure the good press effect. The large and small press wheels are controlled by the separate pressure control valve.

Optional: One large wheel can be equipped with 5 small wheels.

5. End trimming system

Adopt the imported precision linear guider, the automatic profiling tracking and high frequency and high speed motor of 0.37kw to ensure the smooth cut surface.

6. Fine trimming system

Fine trimming motor is 0.75kw high frequency motor. The fine trimming tools are the Φ69mm four tooth carbide cutters with high hardness and wear resistance. The tools processing angle is 45°.

Optional:High-power high-frequency motor 1.1kw.

7. Corner trimming system

To process the round / duck mouth / right angles caused by end trimming to form a perfect round angle.

Use 0.37KW high frequency motor and R2.5,Φ70mm ,3Z carbide tools.

If the work piece has hinge hole or other processing holes on surface, the integrated large profile wheel is optional.

Match big profile wheel to process panels with hinge holes or other processing holes on surface.

8. Scrapping system

It is used for PVC or ABS edge band less than or equal to 3mm. The system adopts high steel structure. Use knob to adjust the arc angle. Each group has two precise profile wheels to ensure the accuracy of cutting point.

9. Hogging system

Single lateral hogging depth can not be over 8mm. If deeper than 8mm, another lateral hogging shall be added. Either side hogging(L) or down hogging(H). It is used for direct slotting of the side plate and drawer bottom plate of wardrobe, and it is more convenient by reducing working procedure of panel saw.

10. Buffing system

The two independent motors equipped with buffing wheels are used for cleaning and buffing after edge banding, easy to operate.

Optional: Pneumatic reciprocating buffing by motors.

edge banding machine wood application:

1.Edge banding machine in woodworking is used in banding edge of desks,carbinet,wardrobe and stright line furniture.The edge bander can be PVC,melamine,wood based works and so on,with powerful fuctions as edge feeding,sticking,material cutting,front-back trimming.

2.Edge banding machine is used to cover the exposed sides of materials such as plywood, particle board or MDF, giving the appearance of a solid (or more valuable) material. Can also be used instead of features such as face frames or molding.