Views: 18 Author: Site Editor Publish Time: 2021-09-27 Origin: Site

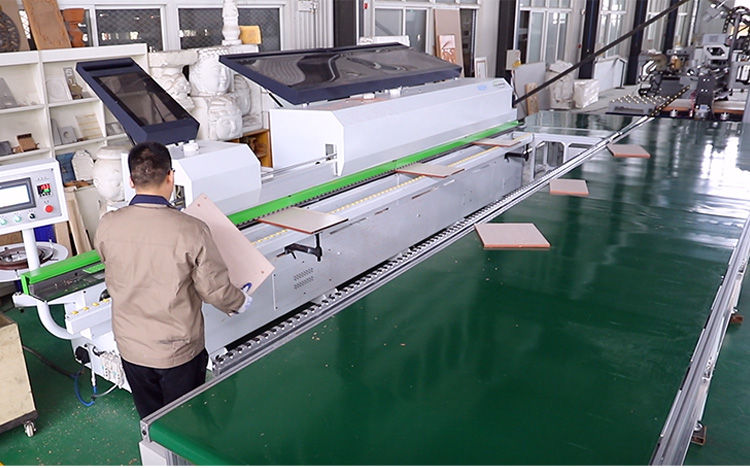

The edge banding machine is suitable for the straight line edge banding and trimming of such plates: MDF, block board, solid wood board, particleboard, polymer door plates, plywood, etc. Function: pre-milling, one-time gluing, bonding and pressing edgeband, cutting edgeband, end cutting, fine trimming, profile, scraping, buffing, slotting and so on. Edge banding is smooth, feel good, and edging line is straight. The machine is stable, reliable and durable, with favorable price. It is especially suitable for large and medium-sized furniture manufacturers that produce furniture, cabinets and other panel furniture.

1.This edge banding machine is suitable for medium density fiberboard, block board, solid wood board, particle board, polymer door board,plywood and other straight edge trimming,etc.

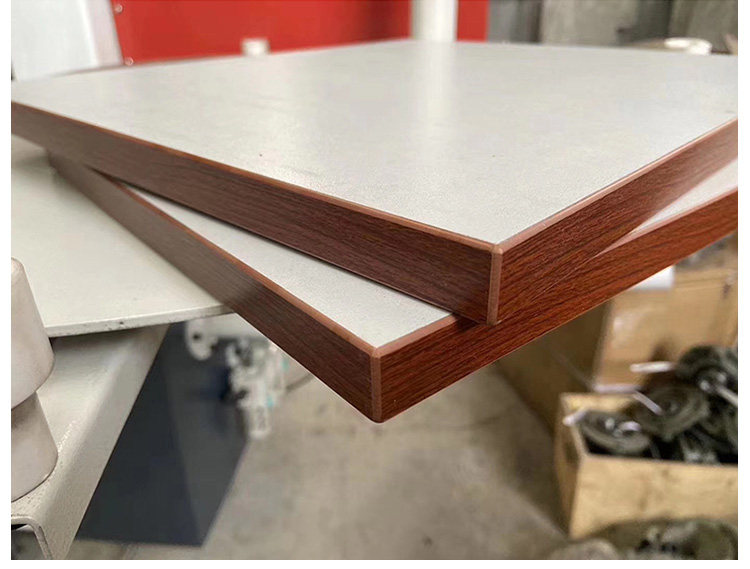

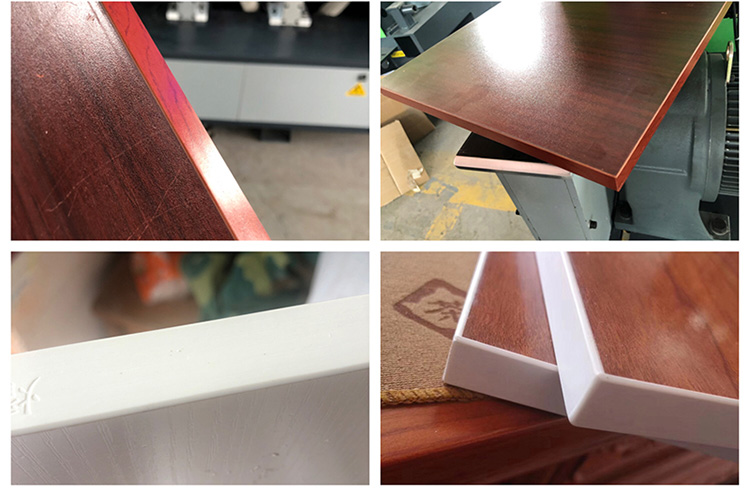

2.The edges are fine, smooth, feel good, and the sealing line is straight and smooth.

3.The equipment is stable, reliable and durable, and the price is moderate. It is especially suitable for furniture, cabinets and other panel furniture manufacturers.

1.Adopt imported motor and high quality electrical component.

2.High precision and work efficiency.

3.Automatic and precise gluing procedure as well as integrated double finish.

4.Glue evenly, conveying stability

Feeding Belt : Made of special material which guarantees long lasting sturdiness & stability. Synchronous teeth of belt & pinion gives high traction & vibration free movement with optimal panel holding.

Gluing, Banding & Edge Cutting : Edges in rolls are loaded automatically and cut precisely to size with a cutter

End Cutting : Pneumatically operated End cutting unit has solid cutter to guarantee a clean, precision cut on the front and rear edges of the panel.

Edge Fine Trimming :

A) Compact and powerful high frequency motors guarantees best finish on top and bottom edges.

B) Unit has copiers which are bearing mounted to ensure smooth panel feed.

C) Very easy precision adjustment of trimming cutters by position indicators.

Buffing : Unit ensure surfaces to give a perfect polishing effect of the edges

Control Panel : Easy accessible user friendly control panel positioned at in-feed, for easy and quick operation

Radius Trim : For Chamfering of the Panel Corner, manually (Radius function Applicable For Model J-4300R.in Only)

Edge Banding Machine is mainly used for straight edge banding of solid wood, chipboard, laminated wood board, medium density fiberboard, etc. It can make the side of the work piece more smooth, durable and beautiful.

edge banding machine Product Parameter:

| Function | Pre-milling、Gluing、 End cltting、Rough trim、 Fine trim、Corner trim、 Scraping、Buffing |

| Sheet thickness | 10-60mm |

| Edge material width | 15-55mm |

| Conveyor belt power | 2.2kw |

| Feeding speed | 15~22m/min |

| Total power | 16.6kw |

| Voltage | 380v |

| Dimensions | 6200*900*1600 mm |

| Package dimensions | 5900*800*1600mm |

| Weight | 1800kg |

| Control System | TaiDa PLC |