| Availability: | |

|---|---|

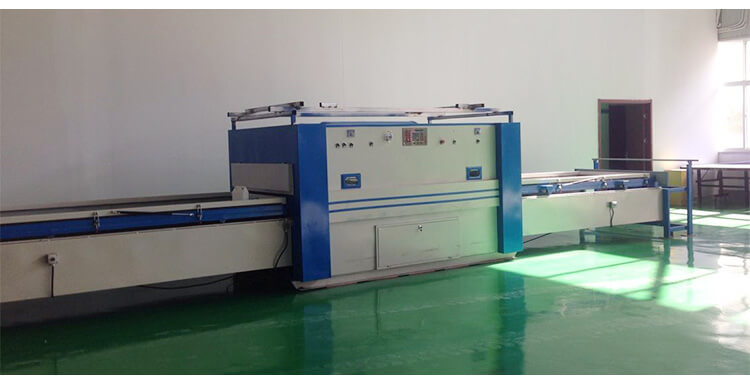

The Latest Automatic Vacuum Press Machine Description:

This Full automatic membrane vacuum press is fully automatic vacuum coating equipment, can be a variety of high-grade PVC , transfer film, leather furniture surface coating of paste.The high degree of automation and simple operation, processing time, working temperature, vacuum value , all automatic control, to ensure product quality, improve production efficiency.

Vacuum Membrane Press Machine Advantages

On the basis of absorbing and transforming Italian production technology, we have developed a new generation of products,Work performance is more stable.

The operating system adopts the B&T touch screen PLC to control the man-machine interface, with advanced technology and automatic High degree of mobility.

The key components of the hydraulic system adopt imported high-quality accessories, which are safe, reliable and excellent in technology.

Directly connected vacuum pump produced with advanced technology has strong horsepower, trouble-free and fast pumping speed.

PVC MDF Door Vacuum Membrane Press Machine Parameter Configuration:

Dimensions | 9470*6170*1500*1400mm |

Work table dimension | 2500*1110*1250mm(the inside diameter) |

Maximum processing height | 60mm,include buttomPlate |

Rated pressure | ≥-0.095MPa |

Total power | 25KW |

Actual power consumption | 12KW |

Total weight | About 2.5T/2.8T |

Power supply | 3ph,380V,50HZ |

Heating system | Iron air dry electric heating tube+Aluminum heat sinks |

Temperature control system | Microcomputer time proportional control, accurate temperature without harmonic pollution |

Traveling | Aluminum housing efficient motor + rack drive |

Vacuum pump | Domestic well - known brand straight rotary vane vacuum pump |

Adsorption | Large flow filter + pure copper solenoid valve, with multiple adsorption function |

Heat preservation | Using high quality rock wool |

Electrical control | Domestic well-known brands of industrial electrical parts, traditional button control |

Automatic Vacuum Membrane Press Machine Features:

1. In addition to stretching the film to be outside the artificial, all automated operation, that is, a key forming.

2. The power of the machine using the international advanced stepper motor, the control part of the use of high-tech PLC digital intelligent system, Panel with a 7-inch high-definition, high-sensitivity touch screen, more intuitive, more convenient, high-end.

3. Transmission part of the high-precision gears and racks combine to bid farewell to the ancient rope pulling exercise, the platform to run more stable, more accurate, never crash collision;

4. Vacuum adsorption pump uses a direct-type, greatly enhance the speed of air pressure, running noise, and other advantages.

Scope of Application

Woodworking Vacuum Membrane Press Machine Application

The automatic pvc film vacuum press machine intended for laminate doors ,kitchen and furnituremachine intended for laminate doors, different furniture units with PVC films and veneer, with the help of heat and vacuum technique system.

As result you will receive product with long life use and the same time

with elegant and inclusive surface.

It is applicable to cover furniture, sound box, cabinets, relief door, decorative panels and all kinds of baroque decorative surfaces with PVC films and natural veneer and hot stamping foils.

Used for PVC laminated furniture, cabinets, sliding doors, audio, decorative wall skirts and various Type finish; PVC, veneer, transfer film can be pasted.

About Us

Shandong iGolden CNC Technology Co., Ltd. is a R&D,manufacturing,sales integration company that specializing in cnc router, laser engraving and cutting machine, plasma cutting machine, cutting plotter,etc.The main configuration all adopt top parts which imported from Italy, Japan,Germany, etc. And welcome to visit us for more choices.

FAQ:

1.How many types of pressing CNC machine do you have?

There are three types of laminating pressing cnc machines, which are fully automatic with standard double stations, fully automatic with large negative pressure, and a high-end machine with positive and negative pressure.

According to the current market, full-automatic double-position standard equipment has more choices.

2.What is the actual size of it?

The area of the double-position of the pressing machine should be 10 meters long areas.

In addition, the working space should be fully prepared for 3 meters.

3.How many types of the pans of the pressing machine?

If you are using for cabinet door and the interior doors, they are processed pots of 1 meter 2 and 1 meter 4, can be more targeted to save the films.

4.How can we choose the suitable door membrance vacuum pressing cnc machine?

If you are processing the movable cnc products, and it is smaller than 30s PVC film, the standard one is the best choice for you. If you are processing interior doors and cabinets doors with more thick PVC films, please use the Large negative pressure series equipment.

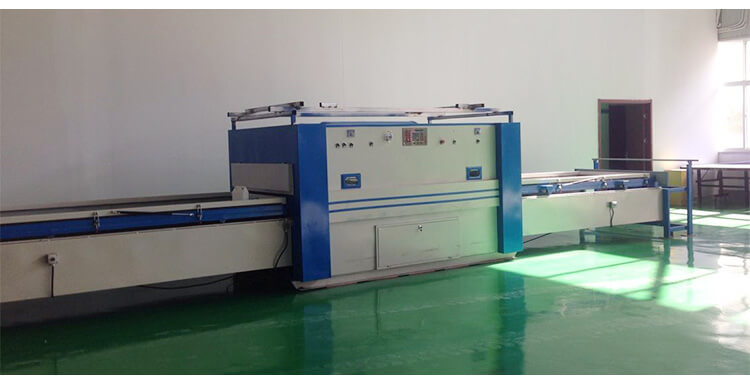

The Latest Automatic Vacuum Press Machine Description:

This Full automatic membrane vacuum press is fully automatic vacuum coating equipment, can be a variety of high-grade PVC , transfer film, leather furniture surface coating of paste.The high degree of automation and simple operation, processing time, working temperature, vacuum value , all automatic control, to ensure product quality, improve production efficiency.

Vacuum Membrane Press Machine Advantages

On the basis of absorbing and transforming Italian production technology, we have developed a new generation of products,Work performance is more stable.

The operating system adopts the B&T touch screen PLC to control the man-machine interface, with advanced technology and automatic High degree of mobility.

The key components of the hydraulic system adopt imported high-quality accessories, which are safe, reliable and excellent in technology.

Directly connected vacuum pump produced with advanced technology has strong horsepower, trouble-free and fast pumping speed.

PVC MDF Door Vacuum Membrane Press Machine Parameter Configuration:

Dimensions | 9470*6170*1500*1400mm |

Work table dimension | 2500*1110*1250mm(the inside diameter) |

Maximum processing height | 60mm,include buttomPlate |

Rated pressure | ≥-0.095MPa |

Total power | 25KW |

Actual power consumption | 12KW |

Total weight | About 2.5T/2.8T |

Power supply | 3ph,380V,50HZ |

Heating system | Iron air dry electric heating tube+Aluminum heat sinks |

Temperature control system | Microcomputer time proportional control, accurate temperature without harmonic pollution |

Traveling | Aluminum housing efficient motor + rack drive |

Vacuum pump | Domestic well - known brand straight rotary vane vacuum pump |

Adsorption | Large flow filter + pure copper solenoid valve, with multiple adsorption function |

Heat preservation | Using high quality rock wool |

Electrical control | Domestic well-known brands of industrial electrical parts, traditional button control |

Automatic Vacuum Membrane Press Machine Features:

1. In addition to stretching the film to be outside the artificial, all automated operation, that is, a key forming.

2. The power of the machine using the international advanced stepper motor, the control part of the use of high-tech PLC digital intelligent system, Panel with a 7-inch high-definition, high-sensitivity touch screen, more intuitive, more convenient, high-end.

3. Transmission part of the high-precision gears and racks combine to bid farewell to the ancient rope pulling exercise, the platform to run more stable, more accurate, never crash collision;

4. Vacuum adsorption pump uses a direct-type, greatly enhance the speed of air pressure, running noise, and other advantages.

Scope of Application

Woodworking Vacuum Membrane Press Machine Application

The automatic pvc film vacuum press machine intended for laminate doors ,kitchen and furnituremachine intended for laminate doors, different furniture units with PVC films and veneer, with the help of heat and vacuum technique system.

As result you will receive product with long life use and the same time

with elegant and inclusive surface.

It is applicable to cover furniture, sound box, cabinets, relief door, decorative panels and all kinds of baroque decorative surfaces with PVC films and natural veneer and hot stamping foils.

Used for PVC laminated furniture, cabinets, sliding doors, audio, decorative wall skirts and various Type finish; PVC, veneer, transfer film can be pasted.

About Us

Shandong iGolden CNC Technology Co., Ltd. is a R&D,manufacturing,sales integration company that specializing in cnc router, laser engraving and cutting machine, plasma cutting machine, cutting plotter,etc.The main configuration all adopt top parts which imported from Italy, Japan,Germany, etc. And welcome to visit us for more choices.

FAQ:

1.How many types of pressing CNC machine do you have?

There are three types of laminating pressing cnc machines, which are fully automatic with standard double stations, fully automatic with large negative pressure, and a high-end machine with positive and negative pressure.

According to the current market, full-automatic double-position standard equipment has more choices.

2.What is the actual size of it?

The area of the double-position of the pressing machine should be 10 meters long areas.

In addition, the working space should be fully prepared for 3 meters.

3.How many types of the pans of the pressing machine?

If you are using for cabinet door and the interior doors, they are processed pots of 1 meter 2 and 1 meter 4, can be more targeted to save the films.

4.How can we choose the suitable door membrance vacuum pressing cnc machine?

If you are processing the movable cnc products, and it is smaller than 30s PVC film, the standard one is the best choice for you. If you are processing interior doors and cabinets doors with more thick PVC films, please use the Large negative pressure series equipment.

content is empty!