The ATC nesting CNC machine with line tool changer is equipped with a 9.0kw air-cooled spindle, and independent operation. High speed, high precision, high efficiency and stability. At the same time, it is equipped with multifunction row drilling package and level spindle, which can drill holes, mill grooves,It is suitable for processing various cabinet doors and wooden doors.

| Availability: | |

|---|---|

Multifunctional ATC Nesting CNC Furniture Making Machine Description:

Multifunctional ATC Nesting CNC Furniture Making Machine is equipped with dual tables for wood door making, cabinet door making, home door making, and room door making, the wood door making machine is mainly used for wood door mass production.

CNC Router Wood Door Making Machine Features:

The bed is made of thickened square tube welding bed, which has the advantages of high precision, reliable performance and durability.

The guide rail adopts imported linear square gauge with reliable accuracy; equipped with an automatic lubrication system to ensure that the guide rail is durable.

The limited position adopts the original limit of Japan Omron to improve the accuracy of returning to the origin.

Adopting Taiwan Baoyuan system, efficient and automatic processing, which saves you time and investment costs, and improves production efficiency.

Wood Door Making CNC Router Machine Parameters:

| XYZ working area | 1500*3000*300mm |

| Spindle | Italy HSD Air cooling 9kw ATC spindle+HSD drilling unite + Saw |

| Tool magazine | linear tool magazine 16 pieces |

| Rail | Taiwan xinyue square guide rail |

| Table | T slot table + Vacuum table with 12 Vacuum area |

| Vacuum pump | Air cooling vacuum pump 7.5kw |

| Motor and driver | Digital type Japan Yaskawa servo 850W motor and driver and reducer |

| Inverter | Taiwan Delta 11kw |

| System | Bus communication controller–Syntec FC 60WA with independent control cabinet |

| Bed frame | Thick Heavy Welding duty and precision with iron cast New type structure |

| Other | Spindle dust cover |

| Dust collector pipe | |

| Double bag Dust collector 4.0kw |

Wood Furniture Making Machine Details:

Italy HSD Air cooling 9kw ATC spindle+HSD drilling unite + Saw

linear tool magazine 16 pieces

Horizontal spindle

Left and right drilling and slot milling

Vertical drilling | Drilling left and right

Front and back drilling

Saw blade cutting

T slot table + Vacuum table with 12 Vacuum area

Side-mounted rotary axis

CNC Wood Door Making Machine Advantages:

1. Double working tables for work exchange, which can improve the working effeciency and production.

2. Linear rails on X, Y (Y axis is controlled by two motors) and Z (Taiwan ball screw transmission) axis are used to guarantee high accuracy and stable performance, and support heavy weight. The square sliding blocks are of good dust-proof effect. Automatic oil feeding and lubricating system makes the regular maintenance very easy.

3. Superior high power air-cooling spindle could keep working at low noise level, safeguarding stability for long-time operation.

4. Break-point memory function enables the machine to continue the unfinished work after a work shift or accidents, such as tool breaking.

5. Compatible with many CAD/CAM software, such as Type3, Artcam, Castmate, Wentai, etc.

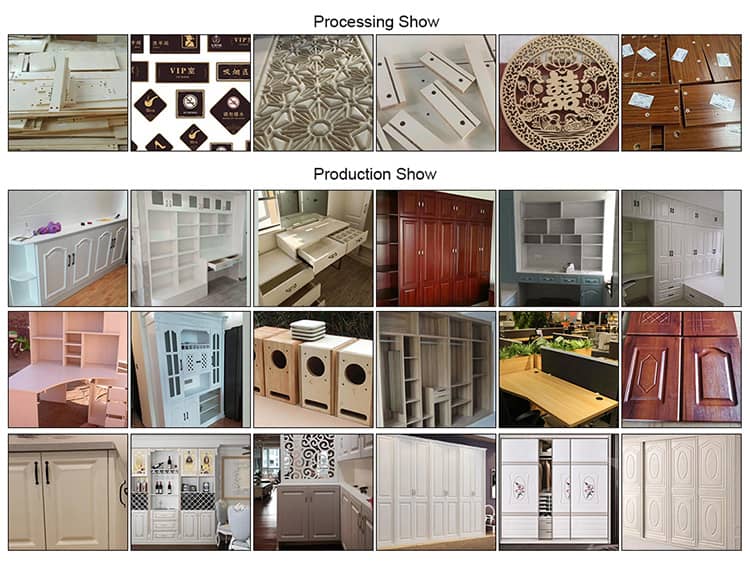

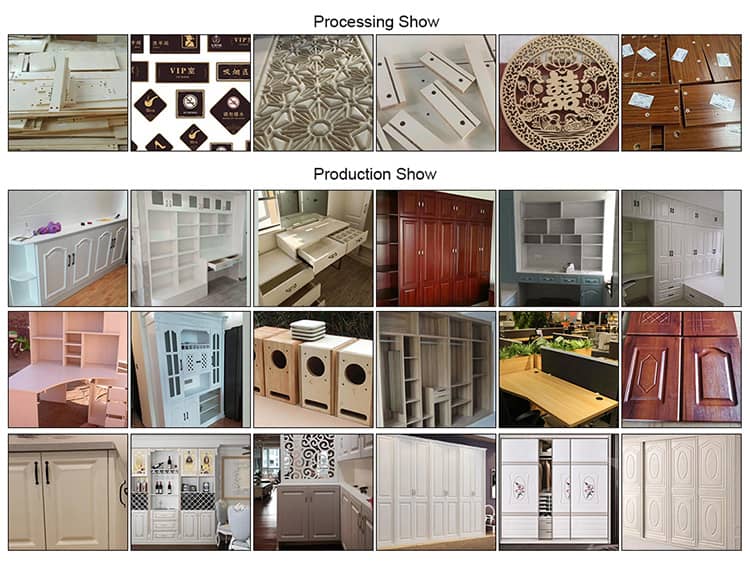

Multifunctional ATC Nesting CNC Furniture Making Machineapplication:

>Production and processing of various types of furniture: cabinets, wardrobes, office furniture, computer tables, children’s furniture, panel furniture, cutting and cutting, slotting and perforating, decoration hollow frames, soft bag background wall production, etc.;

>Wooden door and furniture decoration industry: solid wood and composite door, cabinet door, large-area plate carving, solid wood, panel furniture carving, solid wood art mural carving, etc .;

>Wood products processing: clocks, electrical countertops, sporting goods and equipment;

>Musical instrument industry: three-dimensional curved surface and shape cutting of sculptable musical instruments;

>Crafts industry: photo frames, jewellery boxes.

Multifunctional ATC Nesting CNC Furniture Making Machine Description:

Multifunctional ATC Nesting CNC Furniture Making Machine is equipped with dual tables for wood door making, cabinet door making, home door making, and room door making, the wood door making machine is mainly used for wood door mass production.

CNC Router Wood Door Making Machine Features:

The bed is made of thickened square tube welding bed, which has the advantages of high precision, reliable performance and durability.

The guide rail adopts imported linear square gauge with reliable accuracy; equipped with an automatic lubrication system to ensure that the guide rail is durable.

The limited position adopts the original limit of Japan Omron to improve the accuracy of returning to the origin.

Adopting Taiwan Baoyuan system, efficient and automatic processing, which saves you time and investment costs, and improves production efficiency.

Wood Door Making CNC Router Machine Parameters:

| XYZ working area | 1500*3000*300mm |

| Spindle | Italy HSD Air cooling 9kw ATC spindle+HSD drilling unite + Saw |

| Tool magazine | linear tool magazine 16 pieces |

| Rail | Taiwan xinyue square guide rail |

| Table | T slot table + Vacuum table with 12 Vacuum area |

| Vacuum pump | Air cooling vacuum pump 7.5kw |

| Motor and driver | Digital type Japan Yaskawa servo 850W motor and driver and reducer |

| Inverter | Taiwan Delta 11kw |

| System | Bus communication controller–Syntec FC 60WA with independent control cabinet |

| Bed frame | Thick Heavy Welding duty and precision with iron cast New type structure |

| Other | Spindle dust cover |

| Dust collector pipe | |

| Double bag Dust collector 4.0kw |

Wood Furniture Making Machine Details:

Italy HSD Air cooling 9kw ATC spindle+HSD drilling unite + Saw

linear tool magazine 16 pieces

Horizontal spindle

Left and right drilling and slot milling

Vertical drilling | Drilling left and right

Front and back drilling

Saw blade cutting

T slot table + Vacuum table with 12 Vacuum area

Side-mounted rotary axis

CNC Wood Door Making Machine Advantages:

1. Double working tables for work exchange, which can improve the working effeciency and production.

2. Linear rails on X, Y (Y axis is controlled by two motors) and Z (Taiwan ball screw transmission) axis are used to guarantee high accuracy and stable performance, and support heavy weight. The square sliding blocks are of good dust-proof effect. Automatic oil feeding and lubricating system makes the regular maintenance very easy.

3. Superior high power air-cooling spindle could keep working at low noise level, safeguarding stability for long-time operation.

4. Break-point memory function enables the machine to continue the unfinished work after a work shift or accidents, such as tool breaking.

5. Compatible with many CAD/CAM software, such as Type3, Artcam, Castmate, Wentai, etc.

Multifunctional ATC Nesting CNC Furniture Making Machineapplication:

>Production and processing of various types of furniture: cabinets, wardrobes, office furniture, computer tables, children’s furniture, panel furniture, cutting and cutting, slotting and perforating, decoration hollow frames, soft bag background wall production, etc.;

>Wooden door and furniture decoration industry: solid wood and composite door, cabinet door, large-area plate carving, solid wood, panel furniture carving, solid wood art mural carving, etc .;

>Wood products processing: clocks, electrical countertops, sporting goods and equipment;

>Musical instrument industry: three-dimensional curved surface and shape cutting of sculptable musical instruments;

>Crafts industry: photo frames, jewellery boxes.

content is empty!