Views: 45 Author: Site Editor Publish Time: 2021-09-22 Origin: Site

Product Description

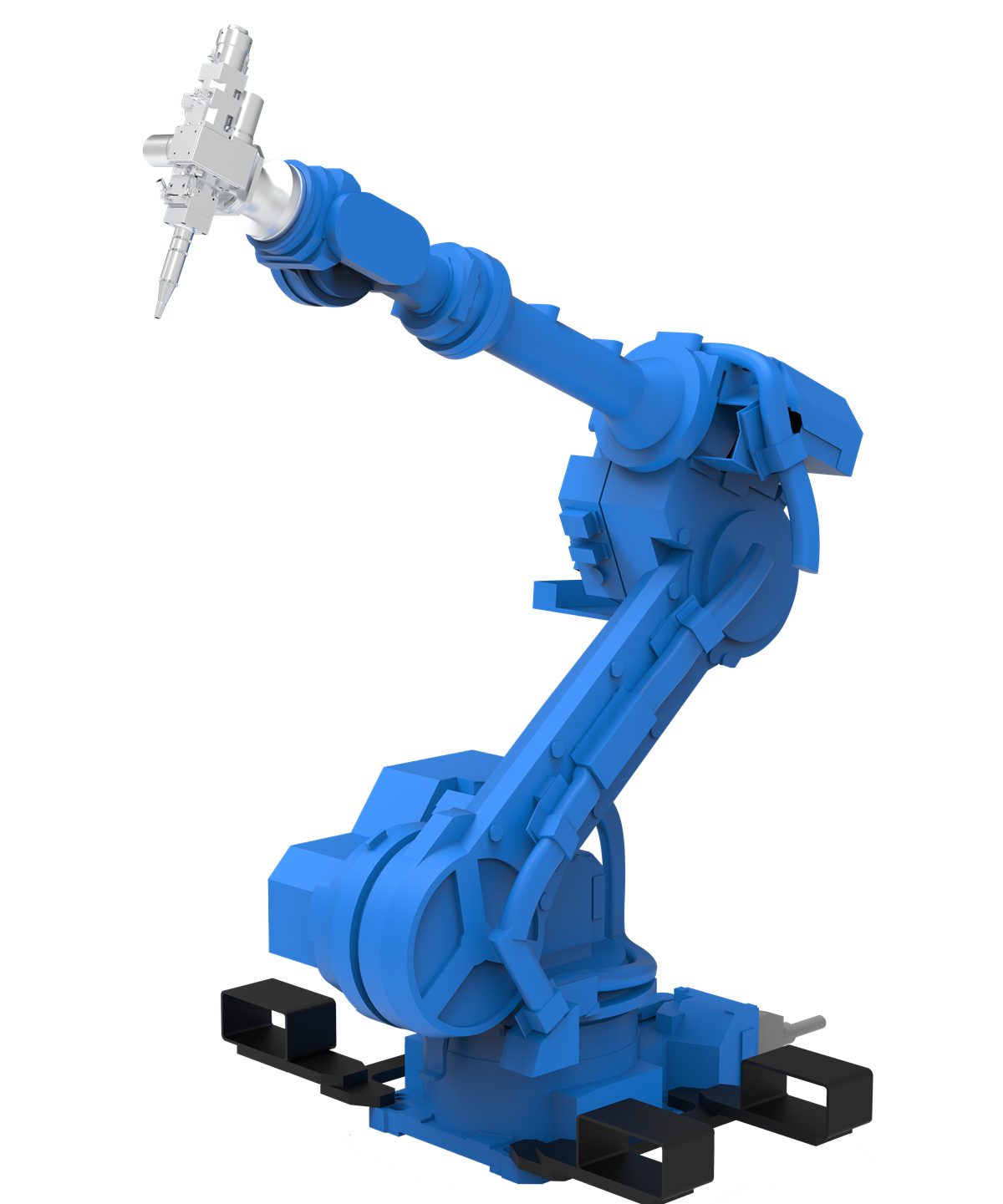

1. The robot has six-axis linkage, high positioning accuracy, large processing range, and easy welding of three-dimensional workpieces.

2. Compared with the traditional argon arc welding, the laser welding speed is increased by 5 to 10 times, and the power consumption and the consumption of consumables are lower, and the welding quality is very stable.

3. The heat affected area of welding is smaller, which can better guarantee the quality of welding products.

4. Laser Welding Machine has good adaptability to the size and shape of welding materials and welding parts, and can realize automatic control and long-distance welding

Features of Laser Welding Machine:

High-quality beam with high-output(4 kW) by Direct Diode Laser oscillator

Low distortion & high-speed welding

High energy density allows low heat input welding.

Lower running cost

Energy conversion efficiency is more than 3 times as high as LD pumped YAG Laser, which reduces electricity costs.

Great condition tolerance

Increased tolerance for gap and target point misalignment (Unique Spiral process and Spinning process)

Easy-to-use software exclusively for Laser welding

Easy settings of weld conditions with Teach Pendant

High functionality trepanning head - Compact, lightweight, and easy maintainability

Compact robot specialized for Laser welding

Cables and hoses are routed through robot arm.

All operations can be performed through teach pendant.

Advantages of Robotic Fiber Laser Welding Machine

Stable welding quality, high precision, small deformation, high penetration, no weld penetration.

Intelligent operation

Intelligent operation, flexible and reliable, six-axis linkage, welding in any space, not limited to plane welding;

High efficiency

Improve workers' working conditions and reduce the requirements for workers' operating skills,increase production and factory efficiency.

Multi-station available

Double-station or multi-station welding operation saves product installation fixture time and greatly improves production efficiency

It works on the principle that when electrons of an atom gets excited by absorbing some energy. And then after some time when it returns back to its ground state, it emits a photon of light. The concentration of this emitted photon increased by stimulated emission of radiation and we get a high energy concentrated laser beam.

Light amplification by stimulated emission of radiation is called laser.

First, the setup of welding machine at the desired location (in between the two metal pieces to be joined) is done.

After setup, a high voltage power supply is applied to the laser machine. This starts the flash lamps of the machine and it emits light photons. The energy of the light photon is absorbed by the atoms of ruby crystal and electrons get excited to their higher energy level. When they return back to their ground state (lower Energy state) they emit a photon of light. This light photon again stimulates the excited electrons of the atom and produces two photons. This process keeps continue and we get a concentrated laser beam.

This high concentrated laser beam is focused to the desired location for the welding of the multiple pieces together. Lens is used to focus the laser to the area where welding is needed. CAM is used to control the motion of the laser and workpiece table during the welding process.

As the laser beam strikes the cavity between the two metal pieces to be joined, it melts the base metal from both the pieces and fuses them together. After solidification, we get a strong weld.

This is how a laser Beam Welding Works.

Machine Parameters

Model | iGWL-RW- 1500 | iGWL-RW- 2000 | iGWL-RW- 3000 | |

Laser power | 1500W | 2000W | 3000W | |

Laser wavelength | 1080±10nm | |||

Robot | FANUC--Six-axis welding robot | |||

Maximum load on wrist | 12KG | |||

Repositioning accuracy | ±0.03mm | |||

Range of motion |

Lower arm | J1 | 340º/370º | |

J2 | 235º | |||

J3 | 455º | |||

Upper arm | J4 | 380º | ||

J5 | 380º | |||

J6 | 900º | |||

Max speed |

Lower arm | J1 | 260º/s | |

J2 | 240º/s | |||

J3 | 260º/s | |||

Upper arm | J4 | 430º/s | ||

J5 | 450º/s | |||

J6 | 720º/s | |||

Thickness of welding material | ≤4mm | ≤6mm | ≤8mm | |

Welding gap requirements | ≤0.3mm | |||

Voltage | 380V±10% | |||

Total power | ≤8kw | ≤10kw | ≤12kw | |

Gross weight | 200KG | |||

Remarks: Can be customized according to customer requirements | ||||

Laser Welding Machine Applications

Suitable for automotive sheet metal, bathroom hardware, pesticide agricultural

Industry machinery pump body parts, automobile fenders, yacht metal back plate welding, etc.