Views: 36 Author: Site Editor Publish Time: 2022-03-05 Origin: Site

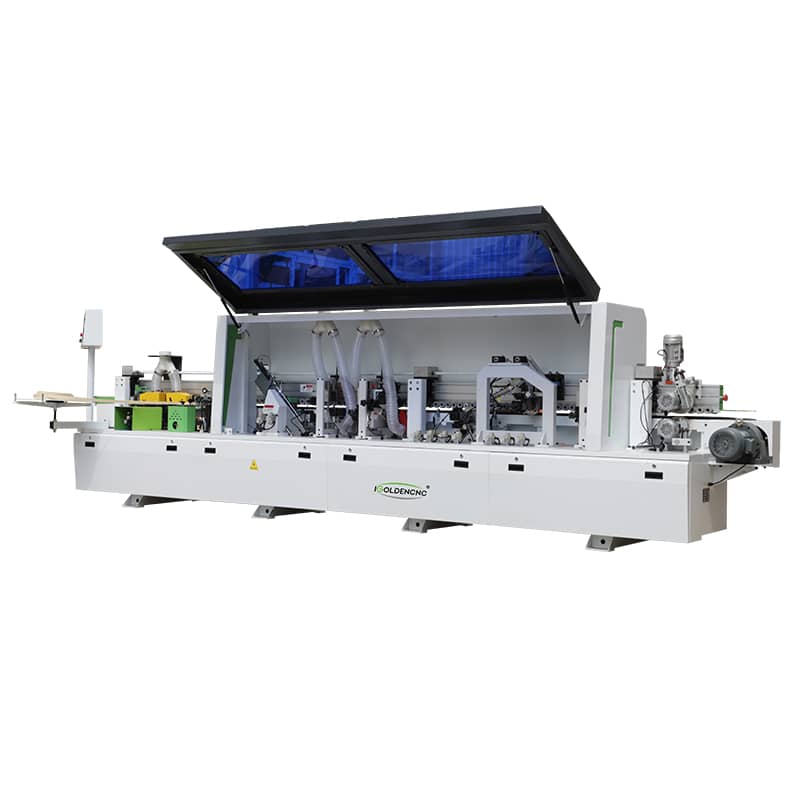

The range of automatic edgebanding machines for wood, designed for artisan producers and companies looking for simplicity, customized production and flexible solutions.

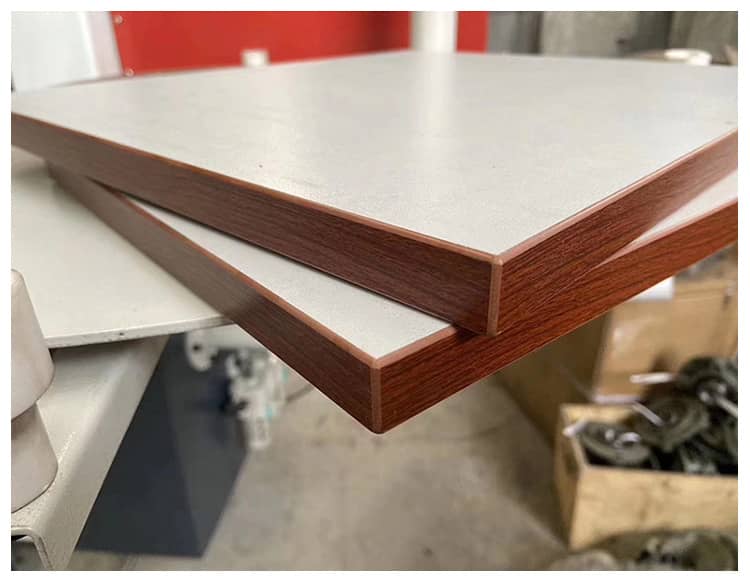

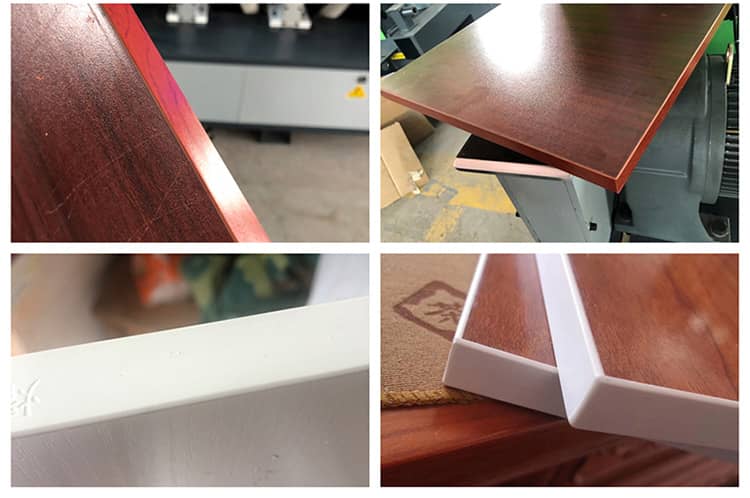

The CNC automatic edge banding machine is a highly automated machine that replaces the manual edge banding procedures (loose, pre-milling, glueing, cutting, flushing, rough trimming, fine trimming, scraping, polishing, grooving, profiling tracking) machine. The edge banding process is a very important process in the manufacturing process of panel furniture.

Highly Cost Effective Function Edge Banding Machine

This machine is suitable for linear edge banding and edge banding materials of solid wood board, fiberboard, particle board and other plate workpieces.

Small Edge Banding Machine

Small Edge Banding Machine This machine is suitable for edge sealing of MDF, particleboard, solid wood board, ecological board, plywood, etc. This machine is stable and reliable, durable, price concessions, especially suitable for home decoration production.

Small Curved Straight Edge Banding Machine

Small Curved Straight Edge Banding Machine This machine is suitable for medium density fiber board, blockboard, wood panels, particleboard, plywood and other polymer doors, straight edge trimming, disposable with double-sided adhesive tape cutting edge bonding edge pressing, block, chamfer, Tinker, finishing, polishing and other functions of scraping edge, edge smooth, smooth, feel good sealing wire, flat and smooth. The equipment operation is stable, reliable and durable, is especially suitable for large and medium-sized furniture, cabinets and other furniture manufacturers plate using.

Application:

Edge banding machine in woodworking is used in banding edge of desks,carbinet,wardrobe and stright line furniture.The edge bander can be PVC,melamine,wood based works and so on,with powerful fuctions as edge feeding,sticking,material cutting,front-back trimming,roughing,fine finishing,scraping and buffing,with features as follows:

1) Adopt high-power and high frequency motor to improve effect

2)The pressure beam is made of high strength aluminum alloy heavy structure, which makes the material more stable and efficient during operation.

3)The imported trachea has high flexibility, winter frost resistance, no burst, frost resistance, fatigue resistant cable and more extended service life.

4) The frame plate, cold plate welding, after welding after annealing processing, the machine in the production process without affecting the internal stress and deformation.