Views: 15 Author: Site Editor Publish Time: 2021-12-25 Origin: Site

Fiber laser welding machine handheld with wire adopts the latest generationof fiber laser to realize multi-fiber simultaneous output. Compared with traditionalhard optical output system, it can improve the degree of processing freedom, and cansimultaneously process multiple beams and multiple stations. Machining provides conditions for more precise welding. It has the advantages of simple operation, beautiful weld seam, fast welding speed and no consumables. It can be welded inmetal materials such as thin stainless steel plate, iron plate and galvanized plate, which can perfectly replace traditional argon. Arc welding, electric weldingand other processes.

The handheld fiber laser welding machine can be widely used in complex and irregular welding processes in kitchen cabinets, stair elevators, shelves, ovens, stainless steel door and window guardrails, distribution boxes, and stainless steelhomes.

Can quickly learn to operate, for you to save expensive technical labor costs! This product operation is simple and convenient, raw and experienced hands can be on the machine operation, for you to solve the technical talent difficult to recruit, technical talent high wages!

The Worker is efficient and does not work tired! Hand-held rapid positioning welding, do not need to move the workpiece, just move the hand-held welding head can be fast welding, high working efficiency,

Clean work, improve the image of the company! Hand-held laser welding machine in work, welding smokeless, no strong light, ultra-low noise, no matter the size of the workpiece, how complex can be welded, welding precision, meticulous.

Application field of fiber laser welding machine handheld with wire:

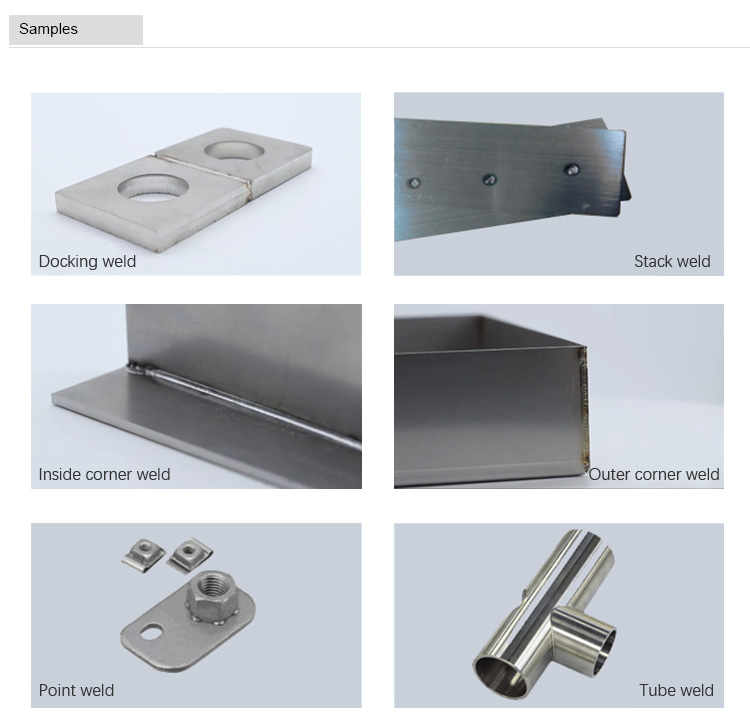

Mainly for large and medium-sized sheet metal, cabinets, chassis, aluminum alloy door and window frames, stainless steel wash basins and other large workpieces, such as inner right angle, outer right angle, flat weld welding, small heat-affected area during welding, small deformation, and welding depth Large, strong welding. Widely used in the kitchen and bathroom industry, home appliance industry, advertising industry, mold industry, stainless steel products industry, stainless steel engineering industry, doors and windows industry, handicraft industry, household goods industry, furniture industry, auto parts industry, etc.

Machine Parameters

| Laser Power | 1000W/ 1500W/ 2000W |

| Laser Wavelength | 1070NM |

| Fiber Length | Standard 8-10M supports up to 15M |

| Way of Working | Continuous/ Modulation |

| Speed Range of Welding Machine | 0-120mm/s |

| Cooling Water Machine | Industrial Constant Temperature Water Tank |

| Working Environment Temperature Range | 15~35°c |

| Recommended Welding Thickness | 0.5~5mm |

| Welding gap requirments | ≤0.5mm |

| Operating Voltage | AV 220V |

1.The internal design is smart, good interactive control system, expanding the tolerance range of processing parts and weld width.

2.The shape is light, the body engineering design method is adopted, the grip is comfortable, the control is easy and the operation is simple Easy to use.

3.The utility model has the advantages of multiple safety alarms, automatic light locking after removing the workpiece, and high safety

4.Beautiful Weld, fast speed, no consumables, no weld marks, no color change, no need to later grinding.

5. Can be equipped with a variety of angle nozzles to meet different product welding needs.