Views: 4 Author: Site Editor Publish Time: 2021-10-11 Origin: Site

For many woodworkers, replacing manual machinery with CNC machinery is the beginning of woodworking as a “business.” If you have reached this point in your woodwork, IGOLDENCNC can help you identify and acquire the right equipment. In addition to selling new and used woodworking machines,

CNC woodworking is our CNC router for the woodworking cabinet industry. According to customer needs and special markets, IGOLDENCNC company designed and manufactured this Multi-spindle Wood Router for wooden furniture research. The price of this Multi-spindle Wood Router is very competitive and the quality is very good. The Woodworking CNC Machine can realize functions such as engraving, drilling, cutting, leading edge, and milling. The two-, three-, and four-step switch head and tool change process can be realized automatically without interruption.

This cnc woodworking is reinforced and thickened with a heavy-duty gantry. The steel plate is processed by precision cutting, planing, and welding, which is equivalent to the secondary tempering treatment, which ensures the long-term durability of the gantry without deformation. The integral cast iron side plate carries out high temperature adjustment to prevent the deformation of the side plate from affecting the stroke accuracy of the Y axis. The main configuration of the woodworking cnc machine includes HQD air-cooled shaft, KND servo motor driver, Taiwan TBI ball screw, HIWIN square rail, dust collector and vacuum adsorption table, all of which can strongly adsorb materials in different areas. Small plate processing has no displacement, the processing surface is smooth, and the plate size is accurate.

1. Automated systems

We’re suggesting CNC Wood Router because of its ability to automate processes.

In the manual method, you need to do all the tasks manually, and you need at least one person always standing beside the machine.

But once you set and start the CNC, then it will do your work automatically.

2. Accurate cut

One of the main advantages is their ability to make precise cuts. As compared to the conventional manual cutting method, CNC routers are controlled by CAD software, which has made cutting difficult and precise materials much easier.

3. Expanded cutting area

A CNC wood router is the machine of choice if your woodwork is headed in the direction of mass-produced parts with a small margin for error.

Standard routers can struggle to produce large pieces like stair risers, particularly when it comes to accuracy.

Large CNC routers, on the other hand, are perfectly capable of producing such products.

A CNC wood router is the machine of choice if your woodwork is headed in the direction of mass-produced parts with a small margin for error.

4. Repeatability

CNC technology’s advanced computerized feature can cut and replicate to a thousandth of an inch.

This work is exact, but it also stays that way from the first cut to the thousandth.

This feature of CNC routing is invaluable for companies that put a high emphasis on quality assurance.

5. Decrease wastage

If waste bits accumulate on your work surface, that means you are wasting money on squandered materials.

Blunders in workpieces are a constant risk with standard routers since they lack the precision control of CNC routers.

As CNC routers are operated with computers, they can easily remove waste work caused by human error by creating thousands of identical parts without producing any wastage.

6. Versatility

It is often seen that some business owners may hesitate about whether to use CNC because they are unsure whether it is appropriate for their particular operation.

CNC routers can be used in various industries and applications, such as furniture and cabinet manufacturing, sign manufacturing, prototyping, etc.

Some CNC routers can cut up to 30 different materials, including wood, steel, foam, plastic, acrylic, and other materials.

These machines are ideal for those that need a single design to be cut repeatedly and can be left unattended to keep the production line going.

7. User Friendly

Sometimes CNC can not take place in the choice list of many small business owners who do not have any trading experience because they think this technology is challenging to master.

But the matter of comfort is that even for first-time CNC users, CNC operation is simple to grasp.

CNC machine tools are simple to use once you learn how to use them. Advanced machine control and programming capabilities have made complex machining operations simpler.

When using CNC machines for manufacturing products that have passed inspection, the following parts must be inspected at the very least.

Furthermore, machine operators may make adjustments or upgrades with little cost or delay.

8. Safety

CNC routing keeps the router user away from the router’s cutting systems. This results in a better working environment.

This will mean fewer workers’ compensation claims and fewer production losses due to worker disability for businesses.

9. Boost Productivity

CNC technology makes it possible to streamline the manufacturing process and complete high-quality projects in a limited amount of time.

CNC-equipped workshops can reduce hours of work to minutes.

A CNC machine’s computer output can potentially handle the workload of five employees at once.

More effective manufacturing operations will help you save money on labor and materials while also improving product quality and increasing income.

Overall, CNC can improve your working efficiency.

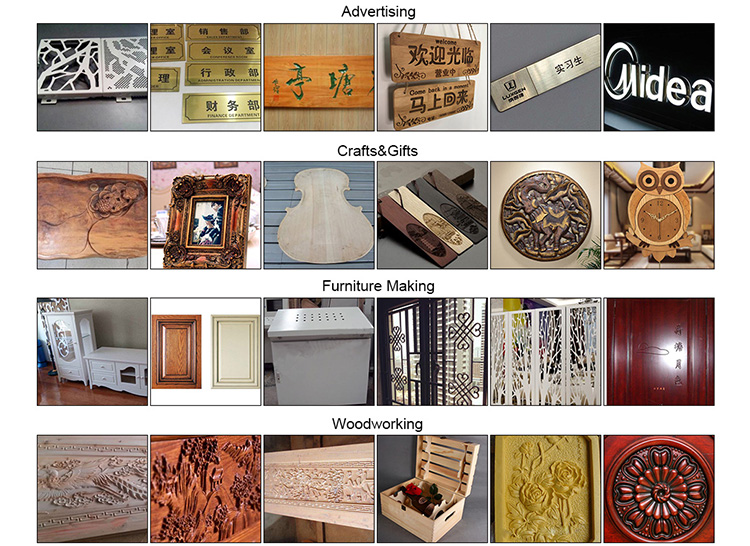

Scope of application