Views: 18 Author: Site Editor Publish Time: 2022-04-26 Origin: Site

CNC Plasma cutter, also known as electric cutting, is through the plasma power to convert ordinary industrial electricity into high-energy plasma arc. The energy of plasma arc is used to burn the steel plate, while the compressed gas is used to blow away the residue to form the incision.

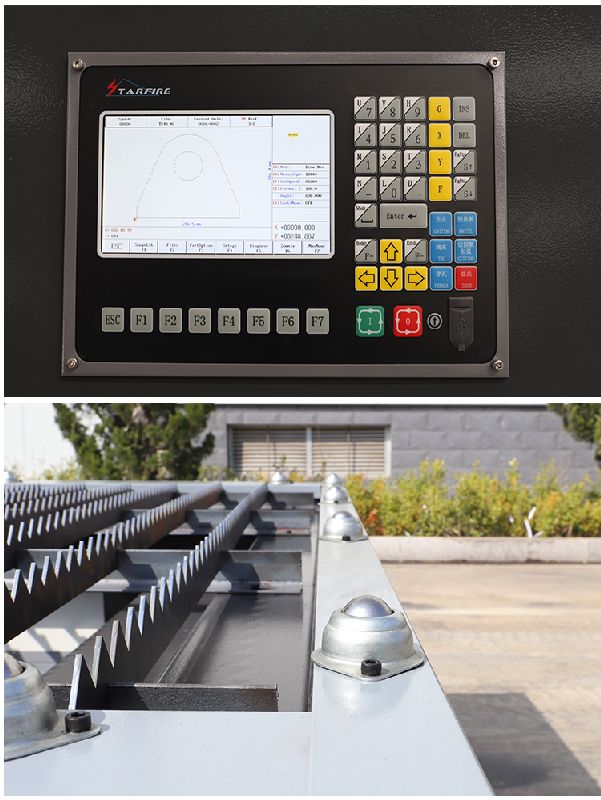

Best cnc plasma cutter adopts rigid welding frame to avoid vibration and high cutting precision. The metal cutting machine is equipped with an automatic arc voltage adjustable device. The plasma flame cutting machine has fast cutting speed, high precision, low cost, thin and neat cutting incision, which can avoid secondary processing.

In general, the defect of slag hanging in the flame cutting section is caused by insufficient oxygen pressure in cutting. The specific performance is the slag hanging on the cutting section or the lower edge, etc. The specific reasons are explained in detail below.

The so-called dross on the lower edge means that continuous dross is generated on, the lower edge of the cutting section. The main causes are the following three points:

1. The cutting speed is too fast or too slow, the cutting nozzle number used is too small, and the cutting oxygen pressure is too low;

2. Excess gas in the preheating flame, the scale of the steel plate is corroded or dirty;

3. The height between the cutting nozzle and the workpiece is too large, and the preheating flame is too strong.

The so-called slag on the cutting section of the best budget cnc plasma cutter means that there is slag on the cutting section, especially in the lower half. The main reason is that the content of the material alloy is too high.

1 X, Y axis adopt rack and pinion. X, Y axis orbit using precision linear compasses, effectively ensure the accurancy of machine operation.

2 Computer graphics, program production, control and processing seamlessly with a computer to achieve full fuctionality, save time, worry, and effort.

3 Mechanical limit, the electronic device to a set limit, so no worries production.

4 Bilateral drive, the configuration of high-power motor, fine points of the drive, with great precision mechanical actuation system, run faster, higher cutting efficiency.

In the 21st century, the CNC cutting industry is facing various new challenges, and the international market competition is becoming more intense. We should aim at the world's advanced level, continue to develop new products, and promote the general improvement of the technical level of the same industry. At the same time, efforts are being made to strengthen scientific research and development, technological innovation, and quality management.