Views: 10 Author: Site Editor Publish Time: 2022-04-27 Origin: Site

What is the wood cutting CNC machine

The cnc wood working machine is a machine specially used to process wood. It has faster cutting efficiency, higher cutting quality, and is safer than ordinary motors. You can use it to perform a series of processing on wood, and you can also repeat these processes later. If you need to process wood multiple times, then the CNC cutting wood machine is your best choice.

igoldencnc offers numerous types of CNC woodworking cutting machines, consisting of wood cutting CNC router machines, laser cutting wood machines, computer system panel saws, and so on. Each CNC woodworking cutting machine has different designs and configurations. Of course, we also accept customer’s customization requirements, We will make a CNC router machine for you according to your requirements.

1. Fault inquiry and analysis: Inquire about the relevant operators, inquire about the failure of the cutting machine and the operation process of the operator in detail, check whether the system has self-alarm or fault diagnosis, and collect the parameters required for troubleshooting;

2. The authenticity of the information provided by the operator should be identified to prevent human factors from distorting the facts of the fault and affecting the troubleshooting and diagnosis of the fault. Generally, the integrity of the faulty CNC machine tool is observed through external observation;

3. Preliminary diagnosis of failure, through "You need to master the diagnostic skills of CNC cutting machine equipment"

Double-station in-line tool change machining center

The general diagnosis method for the electrical fault of Ccnc wood working machine equipment is:

1. Fault inquiry and analysis: Inquire about the relevant operators, inquire about the failure of the cutting machine and the operation process of the operator in detail, check whether the system has self-alarm or fault diagnosis, and collect the parameters required for troubleshooting;

2. The authenticity of the information provided by the operator should be identified to prevent human factors from distorting the facts of the fault and affecting the troubleshooting and diagnosis of the fault. Generally, the integrity of the faulty CNC machine tool is observed through external observation;

3. Preliminary diagnosis of faults, through the "Common Fault Specifications of CNC Machine Tools" to carry out preliminary definition and diagnosis;

4. Determine the type of failure by comparing the working conditions of other CNC cutting machines.

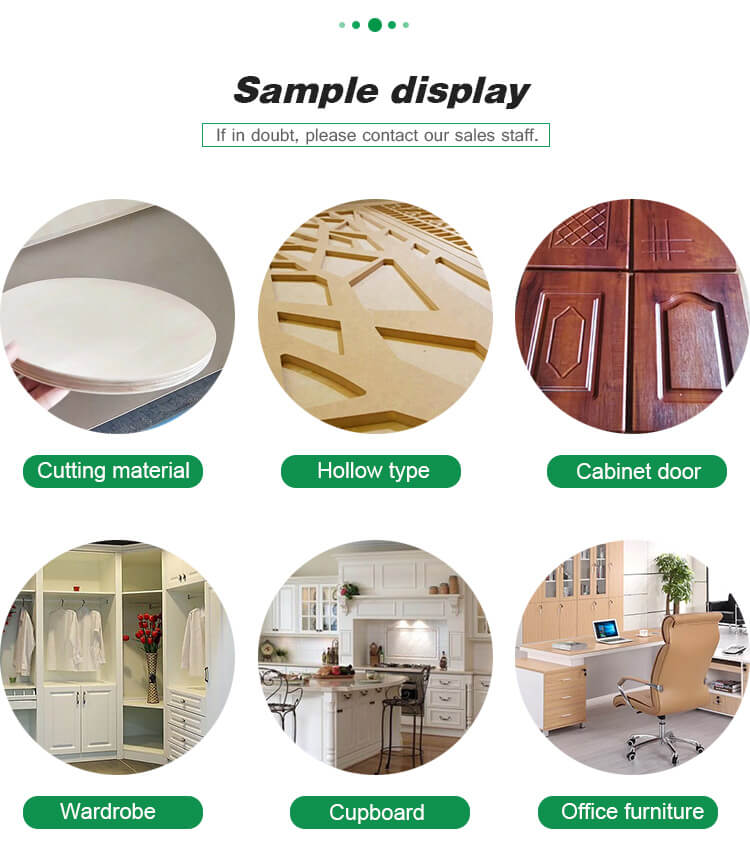

Applications forcnc wood working machine

A CNC router is a computer-controlled cutting device. It can be used for a large range of materials such as wood cutting, MDF cutting, plastics cutting, foams milling, and metals cutting. Compared to a manually operated router, CNC machines can cut at a considerably higher speed, make much smoother edge finishes and produce a series of identical products as well as one-off pieces. So they have an extensive range of applications.

Wood cutting CNC machine application:

Woodworking industry: sculpture, round carving, wooden handcraft processing.

Advertising signs: logo making, cutting acrylic, plastic molding, suit for making a variety of materials advertising decorative products

Other industries: The engraver could do shadow-carved, sculpture which widely used in the gift industry; can be used in aluminum cutting industry, such as aluminum, aluminum-plastic plate, aluminum honeycomb panels, aluminum, 3D engraving process, Artificial plate, cutting LED, making plastic light box model; also can engrave on acrylic, copper, PVC board, artificial stone, MDF board, and other metal sheet.