iGC-AS-RS

iGOLDENCNC

iGC-AS-RS

| Availability: | |

|---|---|

Integrating a 3D storage bin into a panel furniture production line transforms material management by combining vertical space efficiency, automation, and real-time data analytics.

By leveraging automation, connectivity, and real-time monitoring, manufacturers can enhance their productivity, improve product quality, and respond effectively to market trends. This modern approach to manufacturing positions companies to thrive in an increasingly competitive and fast-paced industry.

Automation and Robotics:

Utilizes robotic systems for material handling, assembly, and finishing processes. Robots can perform tasks such as loading/unloading, edge banding, drilling, and packing.

Automated guided vehicles (AGVs) and conveyors streamline material flow and logistics within the factory.

CNC Machinery:

Incorporates CNC routers and laser cutting machines that accurately cut and shape panel materials, ensuring high precision and consistency in production.

CNC machines can be programmed for various designs, allowing for quick changes in production without the need for manual setup.

Integrated Software Systems:

Employs Manufacturing Execution Systems (MES) to monitor and manage production processes in real-time, ensuring optimal efficiency.

enterprise Resource Planning (ERP) software integrates production scheduling, inventory management, and supply chain operations for better decision-making.

IoT and Connectivity:

Integrates Internet of Things (IoT) devices to collect data from machines and equipment, providing insights into performance, maintenance needs, and overall efficiency.

Sensors and smart devices enable remote monitoring and control of machinery, enhancing flexibility in operations.

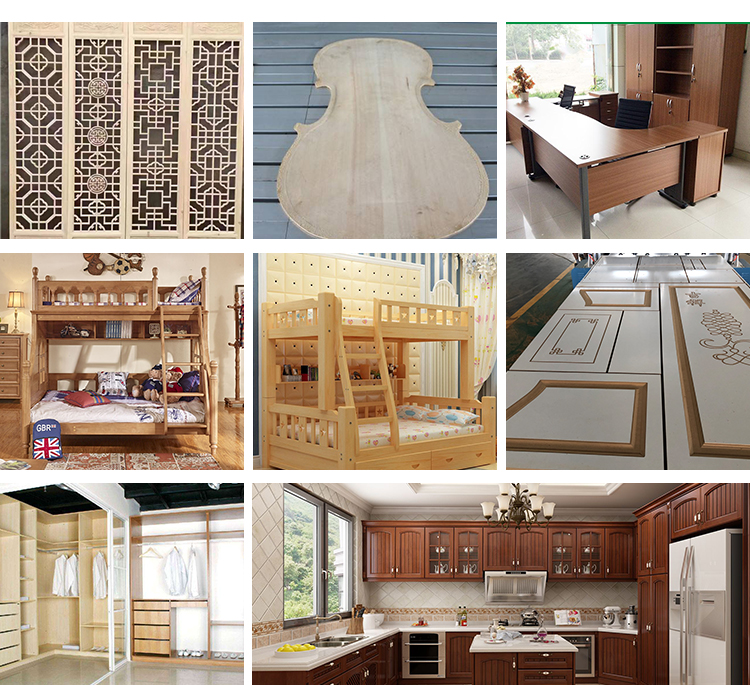

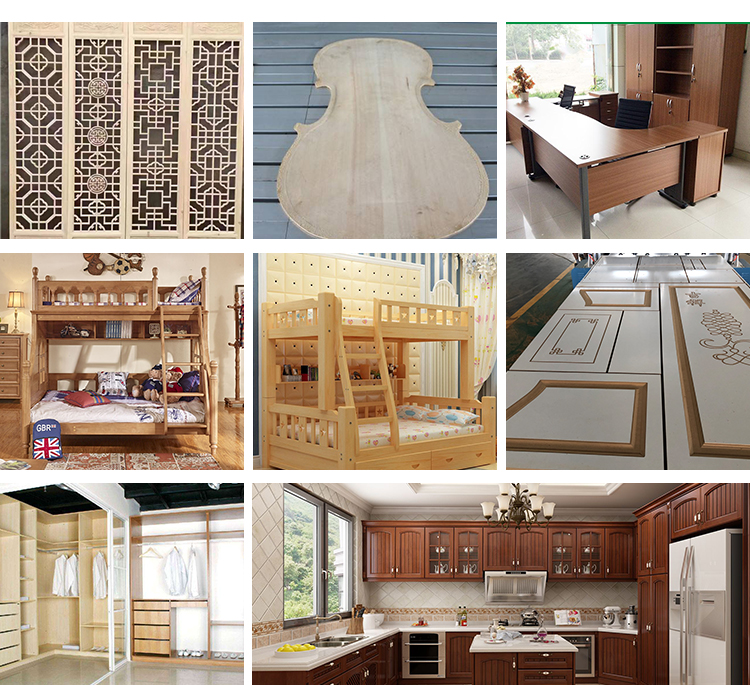

Custom Furniture Design: Accommodates bespoke furniture projects, allowing for rapid prototyping and flexible manufacturing processes.

Mass Production: Ideal for producing large quantities of standard furniture pieces while maintaining quality and efficiency.

Prototype Development: Facilitates quick changes in design and material choices, aiding in the development of new furniture lines.

Integrating a 3D storage bin into a panel furniture production line transforms material management by combining vertical space efficiency, automation, and real-time data analytics.

By leveraging automation, connectivity, and real-time monitoring, manufacturers can enhance their productivity, improve product quality, and respond effectively to market trends. This modern approach to manufacturing positions companies to thrive in an increasingly competitive and fast-paced industry.

Automation and Robotics:

Utilizes robotic systems for material handling, assembly, and finishing processes. Robots can perform tasks such as loading/unloading, edge banding, drilling, and packing.

Automated guided vehicles (AGVs) and conveyors streamline material flow and logistics within the factory.

CNC Machinery:

Incorporates CNC routers and laser cutting machines that accurately cut and shape panel materials, ensuring high precision and consistency in production.

CNC machines can be programmed for various designs, allowing for quick changes in production without the need for manual setup.

Integrated Software Systems:

Employs Manufacturing Execution Systems (MES) to monitor and manage production processes in real-time, ensuring optimal efficiency.

enterprise Resource Planning (ERP) software integrates production scheduling, inventory management, and supply chain operations for better decision-making.

IoT and Connectivity:

Integrates Internet of Things (IoT) devices to collect data from machines and equipment, providing insights into performance, maintenance needs, and overall efficiency.

Sensors and smart devices enable remote monitoring and control of machinery, enhancing flexibility in operations.

Custom Furniture Design: Accommodates bespoke furniture projects, allowing for rapid prototyping and flexible manufacturing processes.

Mass Production: Ideal for producing large quantities of standard furniture pieces while maintaining quality and efficiency.

Prototype Development: Facilitates quick changes in design and material choices, aiding in the development of new furniture lines.