| Availability: | |

|---|---|

CNC wood working machine Furniture Production Line Wood Door Making Machine cnc wood router for kitchen cabinets.

Custom furniture CNC router with automatic nesting software has full functions of automatic uploading and downloading, automatically nesting, optimizing, vertical drilling, slotting, grooving, engraving, etc. now the nesting CNC router for sale at an affordable price.

Fully automatic loading and unloading machining center is suitable for multi-product processing, such as boring and milling, embossing, drilling, cutting and edge cutting. The fuselage is welded by high-strength thick-walled steel pipe, and the structure is stable to ensure stable operation of the machine. The use of internationally imported parts also gives the machine a longer life. In particular, the automatic loading and unloading function is more intelligent, saving manpower and improving processing efficiency.

Nesting CNC Router ATC Tool Changer With Drilling Wood Machine Features:

1. Air cooling spindle with high speed,high efficency and little noise.

2. It's with loading and unloading nesting system, so can save time and have high effiency.

3. Taiwan HIWIN square guide rails and Taiwan TBI ball screws with high precision,large load bearing and stable running.

4. Equipped with professional vaccum adsorption base with the high strength engineering plastics surface in order to ensure can bear large load and longtime working.

5. Adopt high powerful professional vacuum pump,strong adsorption capacity.

Edge Banding Machine

Woodworking Edge Banding Machines Features:

6.Apply to MDF . Acrylic plate . Fiber board . Particle board . Solid Board . PVC board.

4. Please notice that all the specifications can be customized according to your special requirements.

Cabinet Door Sanding Machines Description:

The equipment uses abrasive cloth strips, sisal and abrasive rolls as abrasives to sharpen the edge of the workpiece, the surface burrs and the edge of the workpiece after painting; the function is complete, the processing range is wide, mainly used for the door plate and the bottom plate. Paint polishing, including solid wood doors, composite doors, sticker doors, cabinet doors, wardrobe doors, and other door panels, such as PU, paint panels, primer panels, polishing of white workpieces can be used. It can replace the polishing worker to complete the work efficiently.

Wood Brush Sanding Machine For Cabinet Door Features:

1) It is the surface processing equipment of wood CNC machine, mainly for the rough grinding and primer polishing of wood products.

2) Using frequency conversion speed regulation, the speed can be adjusted freely to select the appropriate feeding speed to ensure the polishing quality of the work piece.

3) The sanding roller is composed of sisal brush and gauze. Different combinations of gauze and brush can be provided. The gauze and brush can be replaced separately, which can effectively save costs.

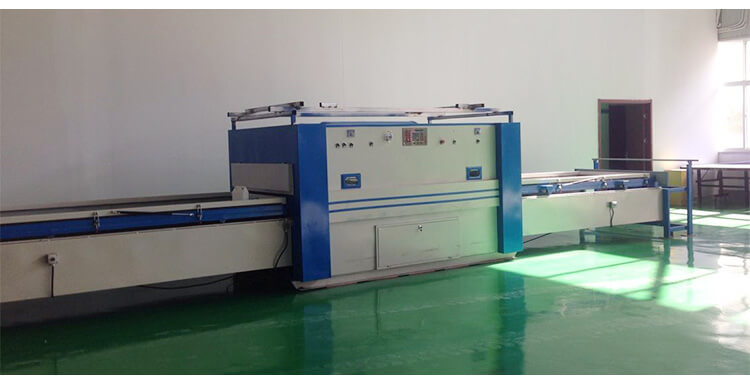

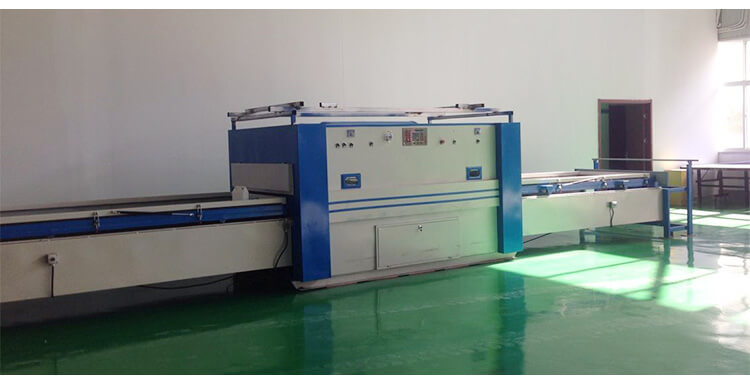

Woodworking MDF Wood Door Surface Vacuum Laminated Press PVC Machine

PVC MDF Door Vacuum Membrane Press Machine Features:

1、Top-e series of special-shaped laminating machine is suitable for panel furniture, cabinet, wardrobe door, sliding door, office table and other home furnishing industries (mainly covering high-grade PVC film, transfer film and other decorative materials on the surface of wood plate).

2、The top-e series model is the latest upgraded version. After the upgraded version, it is mainly reflected in: 1. It reduces the previous tedious operation steps and saves time; 2. It reduces the traditional fault points and improves the working efficiency; 3. The high-quality re upgrading of main components improves the stability.

3、This machine is double station automatic operation mode. The left and right two stations can operate continuously. When the left platform is working, the right platform places the workpiece;when the right platform is working, the left platform places the workpiece. There is no need to wait to maximize efficiency.

4、The operation interface adopts automatic digital display control, which is easy to understand. According to the PVC film of different materials, adjust the corresponding parameters (the factory has provided the parameter table for reference). When operating, just press the start button, which is fast and time-saving.

5、Equipped with high-speed vacuum pump, rated speed of 100m ³ / h and super large vacuum tank. It can quickly reach the required pressure in a short time, with fast pumping speed and large force. Shorten the forming time and improve the working efficiency.

CNC wood working machine Furniture Production Line Wood Door Making Machine cnc wood router for kitchen cabinets.

Custom furniture CNC router with automatic nesting software has full functions of automatic uploading and downloading, automatically nesting, optimizing, vertical drilling, slotting, grooving, engraving, etc. now the nesting CNC router for sale at an affordable price.

Fully automatic loading and unloading machining center is suitable for multi-product processing, such as boring and milling, embossing, drilling, cutting and edge cutting. The fuselage is welded by high-strength thick-walled steel pipe, and the structure is stable to ensure stable operation of the machine. The use of internationally imported parts also gives the machine a longer life. In particular, the automatic loading and unloading function is more intelligent, saving manpower and improving processing efficiency.

Nesting CNC Router ATC Tool Changer With Drilling Wood Machine Features:

1. Air cooling spindle with high speed,high efficency and little noise.

2. It's with loading and unloading nesting system, so can save time and have high effiency.

3. Taiwan HIWIN square guide rails and Taiwan TBI ball screws with high precision,large load bearing and stable running.

4. Equipped with professional vaccum adsorption base with the high strength engineering plastics surface in order to ensure can bear large load and longtime working.

5. Adopt high powerful professional vacuum pump,strong adsorption capacity.

Edge Banding Machine

Woodworking Edge Banding Machines Features:

6.Apply to MDF . Acrylic plate . Fiber board . Particle board . Solid Board . PVC board.

4. Please notice that all the specifications can be customized according to your special requirements.

Cabinet Door Sanding Machines Description:

The equipment uses abrasive cloth strips, sisal and abrasive rolls as abrasives to sharpen the edge of the workpiece, the surface burrs and the edge of the workpiece after painting; the function is complete, the processing range is wide, mainly used for the door plate and the bottom plate. Paint polishing, including solid wood doors, composite doors, sticker doors, cabinet doors, wardrobe doors, and other door panels, such as PU, paint panels, primer panels, polishing of white workpieces can be used. It can replace the polishing worker to complete the work efficiently.

Wood Brush Sanding Machine For Cabinet Door Features:

1) It is the surface processing equipment of wood CNC machine, mainly for the rough grinding and primer polishing of wood products.

2) Using frequency conversion speed regulation, the speed can be adjusted freely to select the appropriate feeding speed to ensure the polishing quality of the work piece.

3) The sanding roller is composed of sisal brush and gauze. Different combinations of gauze and brush can be provided. The gauze and brush can be replaced separately, which can effectively save costs.

Woodworking MDF Wood Door Surface Vacuum Laminated Press PVC Machine

PVC MDF Door Vacuum Membrane Press Machine Features:

1、Top-e series of special-shaped laminating machine is suitable for panel furniture, cabinet, wardrobe door, sliding door, office table and other home furnishing industries (mainly covering high-grade PVC film, transfer film and other decorative materials on the surface of wood plate).

2、The top-e series model is the latest upgraded version. After the upgraded version, it is mainly reflected in: 1. It reduces the previous tedious operation steps and saves time; 2. It reduces the traditional fault points and improves the working efficiency; 3. The high-quality re upgrading of main components improves the stability.

3、This machine is double station automatic operation mode. The left and right two stations can operate continuously. When the left platform is working, the right platform places the workpiece;when the right platform is working, the left platform places the workpiece. There is no need to wait to maximize efficiency.

4、The operation interface adopts automatic digital display control, which is easy to understand. According to the PVC film of different materials, adjust the corresponding parameters (the factory has provided the parameter table for reference). When operating, just press the start button, which is fast and time-saving.

5、Equipped with high-speed vacuum pump, rated speed of 100m ³ / h and super large vacuum tank. It can quickly reach the required pressure in a short time, with fast pumping speed and large force. Shorten the forming time and improve the working efficiency.