F-001

iGOLDENCNC

iGOLDENCNC-F-001

| Availability: | |

|---|---|

CNC Wood Router Woodworking Kitchen Cabinet Door Making Machine

Kitchen Cabinet Door Making CNC Router Machine Features:

1) Automatically uploading and downloading, Automatically Nesting, optimizing cutting orders, drilling, to maximum the productive.

2) Double layer vacuum table can hold small pieces for excellent cutting, realizes all kinds of customaries cabinet.

Auto load and unload Kitchen Cabinets Wooden Door Making Machine is the first choice for enterprises with large production volume. Compared with the traditional manual tool change production method, this type of wood CNC machine has an independent tool magazine with different tool bits. It can automatically change the required tools by computer program control without stopping work during processing. And this CNC wood router can complete a series of cutting, hollowing, grooving, punching, milling grooves, milling planes and other different processing needs.And it has the advantages of high precision and high speed, high efficiency. It is especially suitable for customized furniture production and processing. Therefore, it is suitable for standardized mass production and flexible customized processing, especially good at customized production.

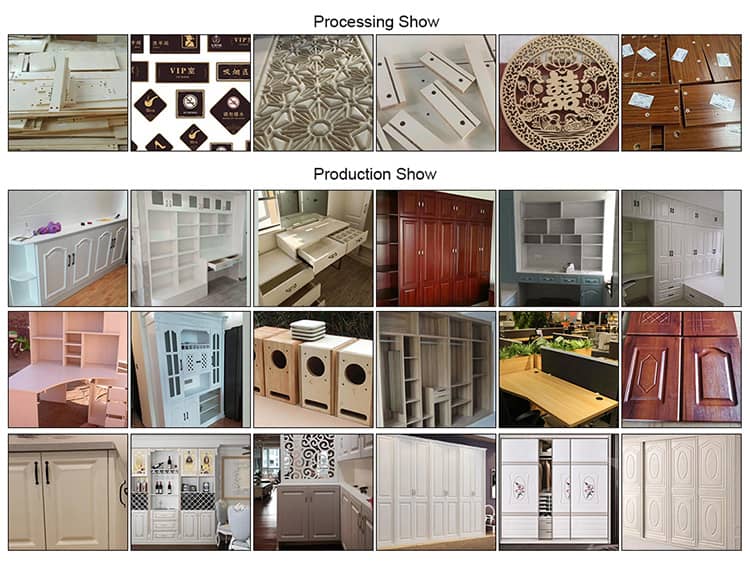

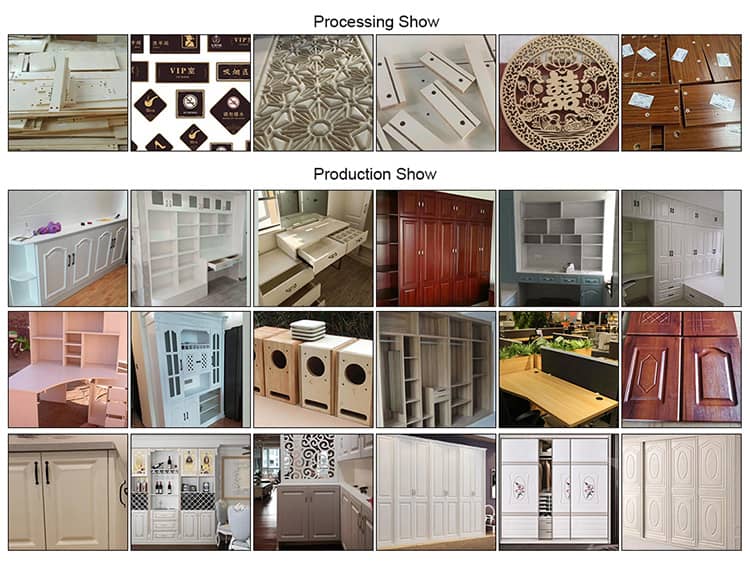

Which Products Need CNC Machines For Making Cabinet Door?

1. Furniture:

cabinet doors, solid wood doors, craft wooden doors, paint-free doors, screens, craft fan windows, tables, chairs, etc. Wooden door cutting, wooden door artwork carving, wave board, 3d photo carving, small or large relief works, cylindrical wood carving, 3d photo carving, etc.

2. Advertising industry:

advertising signs and logos, decorative products, wood, medium density fiberboard, bamboo, plastic, PVC, acrylic, metal, stone, etc.

3. Art industry:

character carving, character carving and cutting, famous brand making, small gift cutting, souvenir making, carving various decorative letters, small windows, fences, figures on walls, etc.

4. Model making:

engraving metal molds such as copper, aluminum and iron, as well as non-metal molds such as marble, sandstone, plastic plates, PVC pipes and wood panels.

5. Other industries:

CNC wood engraving machine can engrave all kinds of large reliefs and shadows, which are widely used in craft gift industry.

Cabinet Door Sanding Machines Advantages:

A new type of high-efficiency wood product surface processing equipment independently developed by the introduction of European technology, mainly for the rough grinding of wood products and primer sanding.

Using frequency conversion speed regulation, the speed can be adjusted freely, and the appropriate feeding speed can be selected to ensure the sanding quality of the workpiece.

The rough grinding roller is composed of sisal brush and emery cloth. Different combinations of emery cloth and brush can be provided, and the brush and emery cloth can be replaced separately to save cost.

Grinding and polishing are easy, high-quality and efficient, which greatly improves production efficiency and reduces production costs.

Membrane Press Machine Advantages:

On the basis of absorbing and transforming Italian production technology, we have developed a new generation of products,Work performance is more stable.

The operating system adopts the B&T touch screen PLC to control the man-machine interface, with advanced technology and automatic High degree of mobility.

The key components of the hydraulic system adopt imported high-quality accessories, which are safe, reliable and excellent in technology.

Directly connected vacuum pump produced with advanced technology has strong horsepower, trouble-free and fast pumping speed.

CNC Wood Router Woodworking Kitchen Cabinet Door Making Machine

Kitchen Cabinet Door Making CNC Router Machine Features:

1) Automatically uploading and downloading, Automatically Nesting, optimizing cutting orders, drilling, to maximum the productive.

2) Double layer vacuum table can hold small pieces for excellent cutting, realizes all kinds of customaries cabinet.

Auto load and unload Kitchen Cabinets Wooden Door Making Machine is the first choice for enterprises with large production volume. Compared with the traditional manual tool change production method, this type of wood CNC machine has an independent tool magazine with different tool bits. It can automatically change the required tools by computer program control without stopping work during processing. And this CNC wood router can complete a series of cutting, hollowing, grooving, punching, milling grooves, milling planes and other different processing needs.And it has the advantages of high precision and high speed, high efficiency. It is especially suitable for customized furniture production and processing. Therefore, it is suitable for standardized mass production and flexible customized processing, especially good at customized production.

Which Products Need CNC Machines For Making Cabinet Door?

1. Furniture:

cabinet doors, solid wood doors, craft wooden doors, paint-free doors, screens, craft fan windows, tables, chairs, etc. Wooden door cutting, wooden door artwork carving, wave board, 3d photo carving, small or large relief works, cylindrical wood carving, 3d photo carving, etc.

2. Advertising industry:

advertising signs and logos, decorative products, wood, medium density fiberboard, bamboo, plastic, PVC, acrylic, metal, stone, etc.

3. Art industry:

character carving, character carving and cutting, famous brand making, small gift cutting, souvenir making, carving various decorative letters, small windows, fences, figures on walls, etc.

4. Model making:

engraving metal molds such as copper, aluminum and iron, as well as non-metal molds such as marble, sandstone, plastic plates, PVC pipes and wood panels.

5. Other industries:

CNC wood engraving machine can engrave all kinds of large reliefs and shadows, which are widely used in craft gift industry.

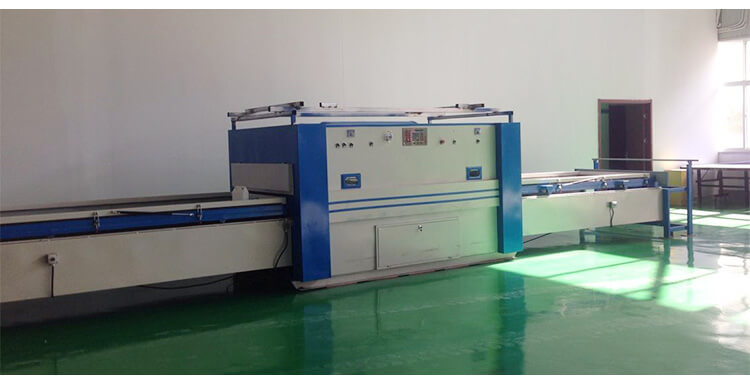

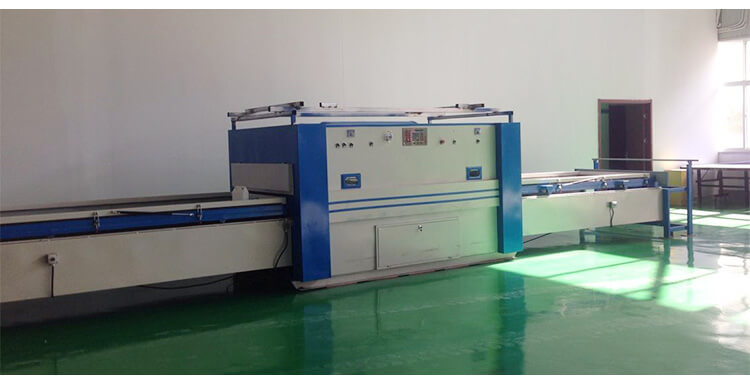

Cabinet Door Sanding Machines Advantages:

A new type of high-efficiency wood product surface processing equipment independently developed by the introduction of European technology, mainly for the rough grinding of wood products and primer sanding.

Using frequency conversion speed regulation, the speed can be adjusted freely, and the appropriate feeding speed can be selected to ensure the sanding quality of the workpiece.

The rough grinding roller is composed of sisal brush and emery cloth. Different combinations of emery cloth and brush can be provided, and the brush and emery cloth can be replaced separately to save cost.

Grinding and polishing are easy, high-quality and efficient, which greatly improves production efficiency and reduces production costs.

Membrane Press Machine Advantages:

On the basis of absorbing and transforming Italian production technology, we have developed a new generation of products,Work performance is more stable.

The operating system adopts the B&T touch screen PLC to control the man-machine interface, with advanced technology and automatic High degree of mobility.

The key components of the hydraulic system adopt imported high-quality accessories, which are safe, reliable and excellent in technology.

Directly connected vacuum pump produced with advanced technology has strong horsepower, trouble-free and fast pumping speed.