| Availability: | |

|---|---|

CNC Wood Working Machine Furniture Production Line For Kitchen Cabinets

The CNC cutting machine can realize the process of material opening, punching and grooving of the board, and is mainly used for the batching of panel furniture and the production of diversified component products (such as cabinets) in the woodworking industry or the cabinet industry. Moreover, it can realize easily implement the shape of various cabinets through the design of intelligent software.

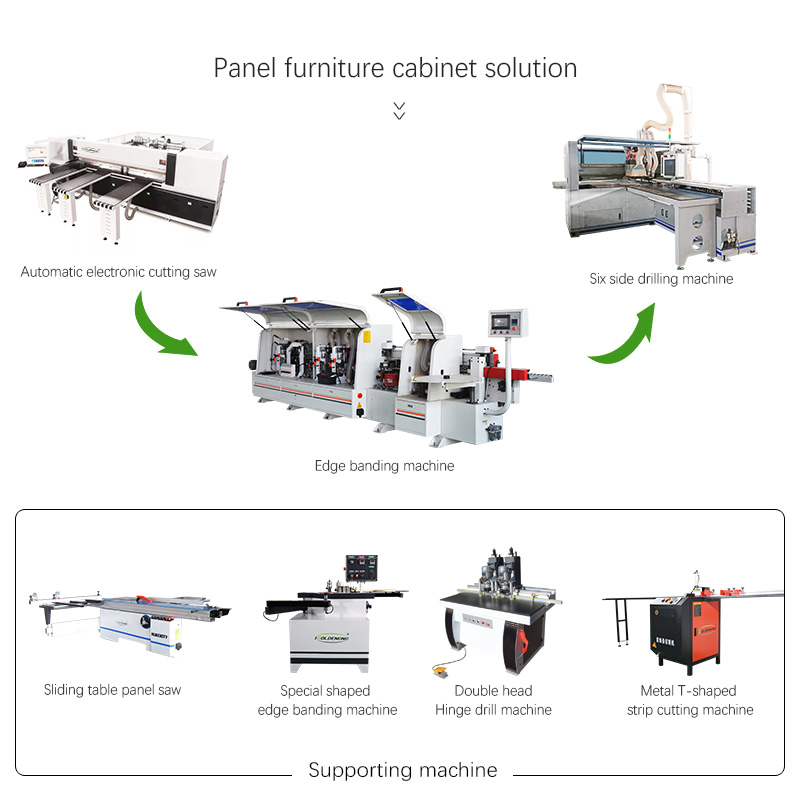

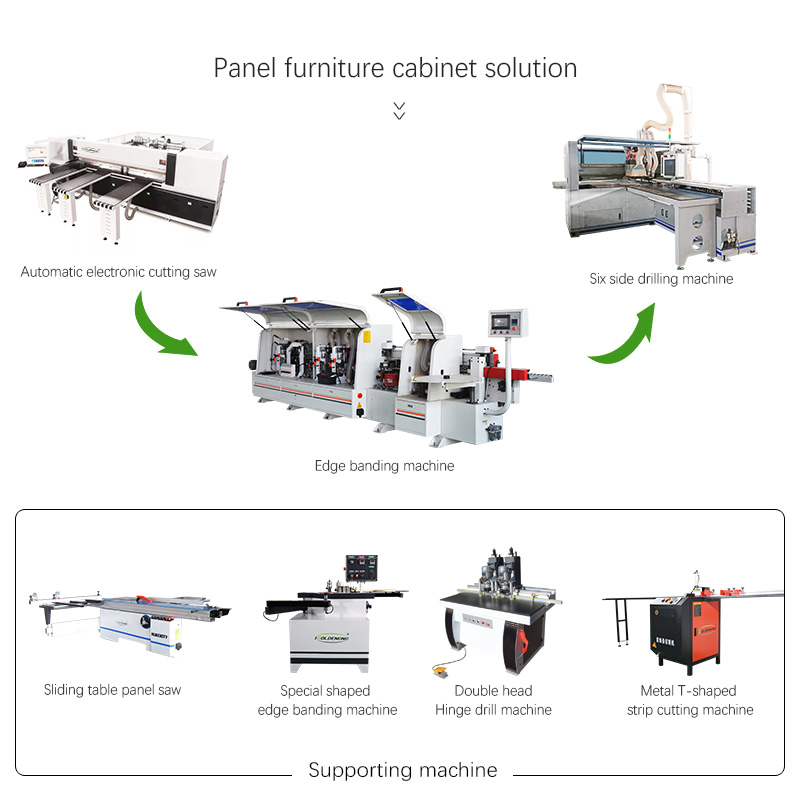

The complete cabinet production line is composed of optimized typesetting software, CNC cutting machine, edge banding machine, side hole machine, drilling machine, and edge banding machine. As the leader of the cabinet production line, iGOLDENCNC can provide double spindle + row drilling Cutting machine, multi-process cutting machine, six-sided drilling, edge banding machine, side hole machine, electric panel saw, profiling corner trimming machine, PTP machining center, three-row drill and other cabinet processing machines, and according to Customer needs and budget are equipped with the most cost-effective and efficient production line plan.

The company has obtained several patents and can produce many types of products, meet the requirements of different customers.

It is automatic nesting cnc router furniture production line with labeling & vertical drilling function. it includes three equipments auto labeling platform, carousel type cnc router atc with boring and auto unloading table. if user need to machining both cabinet such as cupboard/shoebox/cabinet/wardrobe etc with higher efficiency, it is good choice with multifunction. compare to linear type tool magazine cnc atc machine, atc spindle can quickly acquire needed tool in few seconds with this disc type tool changer storage. and the vertical drill head next to spindle is mainly used for drilling required hole into cabinets with fast speed. after workpiece finished, pushing device under gantry can push workpiece to auto unloading table automatically. Generally speaking, it's very suitable for mass production cabinet furniture making.

We efforts to achieve in technology and service in the future self-improvement, and more to create and to provide customers the best products of real value, with first-class technology, first-class products and first class service to our customer side by side to meet the bright future.

ATC CNC Router Cabinet Furniture CNC Nesting Four Process Spindle Wood Router Machine Feature:

| 1. Solid gantry,well structure of lathe bed,stable and high speed,high accuracy. |

| 2. Highspeed air cooling spindle and high performance subdivision driver ensure work stably for long time. |

| 3. With easily-learned sofware,conveniently check the moving path of tool,and adjust the processing depth of Z axis and the speed of motor. |

| 4. Vacuum table with great absorption strengt,high efficient for mass production, cutting speed over 20m/min. Low vibration and smooth motion ensure higher work piece quality. |

Automatic Woodworking CNC Edge Banding Machine

CNC Wood Edge Banding Machine Features:

1.Full-automatic edge banding machine function include glue,head together,rough repair,refine,Scraping edgeand polishing.

2.Have good shape,reasonable layout,has sound arrester,dust collector and overload protection.

3.The main parts of the machine adopt steel plate by laser cutting,one time welded together,the body is firm and undeformed.

4.Can increase or decrease component structure according to actual demand.

Drilling CNC Machinery Wood Furniture Milling Drilling CNC Machine

CNC Drilling And Milling Machine Wood Features:

The cnc drilling and milling machine is a fully automatic side punching device developed for the side hole of the panel furniture triple piece. Plc integrated control, stable and efficient. It can also be adjusted to side groove processing equipment. Achieve a multi-functional machine.

The machine is equipped with American Bonner laser probe to achieve 100% leak-free punching. 3.2KW air-cooled spindle, the feed is fast and vibration-free. The power motor uses the corresponding servo motor, and the precision is controlled within 0.05mm. The transmission components are all supplied in Taiwan with high precision and good stability.

CNC Wood Working Machine Furniture Production Line For Kitchen Cabinets

The CNC cutting machine can realize the process of material opening, punching and grooving of the board, and is mainly used for the batching of panel furniture and the production of diversified component products (such as cabinets) in the woodworking industry or the cabinet industry. Moreover, it can realize easily implement the shape of various cabinets through the design of intelligent software.

The complete cabinet production line is composed of optimized typesetting software, CNC cutting machine, edge banding machine, side hole machine, drilling machine, and edge banding machine. As the leader of the cabinet production line, iGOLDENCNC can provide double spindle + row drilling Cutting machine, multi-process cutting machine, six-sided drilling, edge banding machine, side hole machine, electric panel saw, profiling corner trimming machine, PTP machining center, three-row drill and other cabinet processing machines, and according to Customer needs and budget are equipped with the most cost-effective and efficient production line plan.

The company has obtained several patents and can produce many types of products, meet the requirements of different customers.

It is automatic nesting cnc router furniture production line with labeling & vertical drilling function. it includes three equipments auto labeling platform, carousel type cnc router atc with boring and auto unloading table. if user need to machining both cabinet such as cupboard/shoebox/cabinet/wardrobe etc with higher efficiency, it is good choice with multifunction. compare to linear type tool magazine cnc atc machine, atc spindle can quickly acquire needed tool in few seconds with this disc type tool changer storage. and the vertical drill head next to spindle is mainly used for drilling required hole into cabinets with fast speed. after workpiece finished, pushing device under gantry can push workpiece to auto unloading table automatically. Generally speaking, it's very suitable for mass production cabinet furniture making.

We efforts to achieve in technology and service in the future self-improvement, and more to create and to provide customers the best products of real value, with first-class technology, first-class products and first class service to our customer side by side to meet the bright future.

ATC CNC Router Cabinet Furniture CNC Nesting Four Process Spindle Wood Router Machine Feature:

| 1. Solid gantry,well structure of lathe bed,stable and high speed,high accuracy. |

| 2. Highspeed air cooling spindle and high performance subdivision driver ensure work stably for long time. |

| 3. With easily-learned sofware,conveniently check the moving path of tool,and adjust the processing depth of Z axis and the speed of motor. |

| 4. Vacuum table with great absorption strengt,high efficient for mass production, cutting speed over 20m/min. Low vibration and smooth motion ensure higher work piece quality. |

Automatic Woodworking CNC Edge Banding Machine

CNC Wood Edge Banding Machine Features:

1.Full-automatic edge banding machine function include glue,head together,rough repair,refine,Scraping edgeand polishing.

2.Have good shape,reasonable layout,has sound arrester,dust collector and overload protection.

3.The main parts of the machine adopt steel plate by laser cutting,one time welded together,the body is firm and undeformed.

4.Can increase or decrease component structure according to actual demand.

Drilling CNC Machinery Wood Furniture Milling Drilling CNC Machine

CNC Drilling And Milling Machine Wood Features:

The cnc drilling and milling machine is a fully automatic side punching device developed for the side hole of the panel furniture triple piece. Plc integrated control, stable and efficient. It can also be adjusted to side groove processing equipment. Achieve a multi-functional machine.

The machine is equipped with American Bonner laser probe to achieve 100% leak-free punching. 3.2KW air-cooled spindle, the feed is fast and vibration-free. The power motor uses the corresponding servo motor, and the precision is controlled within 0.05mm. The transmission components are all supplied in Taiwan with high precision and good stability.