Views: 7 Author: Site Editor Publish Time: 2022-05-14 Origin: Site

High definition plasma cutter is a popular method of fabricating metal plate ranging in size from ¼ inch to 1 ½ inches. Its processing speed and high-quality cuts are two of the reasons why this technology is used in fabrication shops of all sizes

A high definition cnc plasma cutter tables for sale is capable of cutting thick metal sheets in any shape and size. This computer-controlled machine gives instructions through a computer over the manual handheld plasma cutter. It is compatible with optional CNC parts and improves the accuracy, flexibility, and productivity.

When you purchase this plasma cutting machine, you will receive plasma cutting software that needs to be installed before operating the machine.

Software Used to Operate the CNC plasma cutting machine

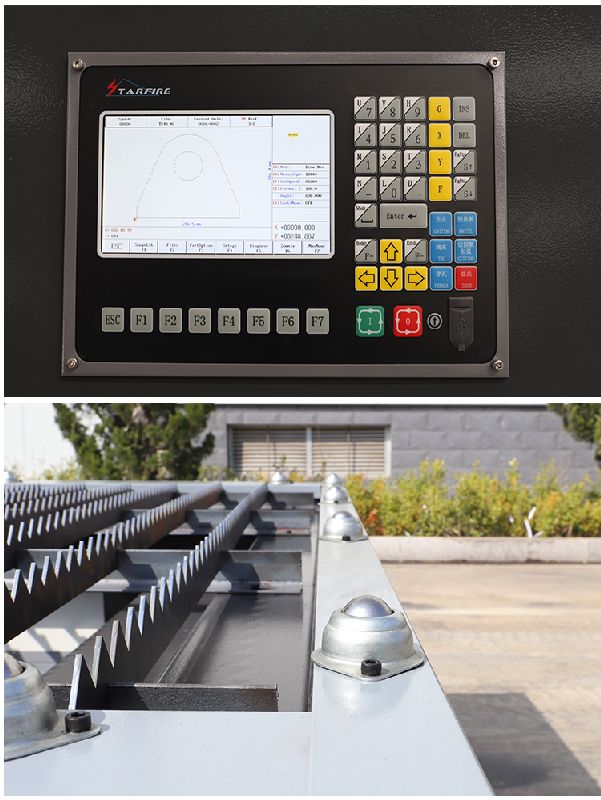

The software that comes with the CNC plasma cutting machine is indubitably one of the most important parts of the machine. It allows the operator to successfully design, cut, and control the operation of the plasma torch. To create top quality designs with the plasma cutter, the operator must use AutoCAD for the CAD part and EXG Code for the CAM portion. The software that actually controls the plasma usually comes along with the CNC plasma table.

CNC plasma cutting software STARCAM is very easy to operate. It consists of 3 modules, first drawing module (StarCAD), nesting module, (StarCUT), and numerical control emulation module (StarTEST). Any layman can read the manual and understand the working process. For more information, you can visit this link https://www.omni-cnc.com/product/starcam-software/. A short training is also given to the new user to make comprehend with the basics of a 4*8 plasma cutting machine. If you are interested in seeing the work process of this machine, you must read plasma machine software in action.

Advantages of high definition plasma cutter:

Moveable

One of the advantages of the plasma cutter is the tool is portable and moveable. If you’re a user of a traditional cutting tool, obviously you know what a pain to move around this massive tool. With the advancements in technology, plasma cutter comes with lightweight and compact design without sacrificing on performances. These lightweight plasma cutters are portable and you can easily move this where ever the job demands. Some brands are so portable that just one person can easily handle this.

Fast Cuts

Working with a plasma cutter is a time saver and lot of easier than other cutting equipment. You can compare the plasma cutter like a warm knife through butter. An industrial plasma cutter can rapidly produce 40,000 degrees F temperatures and you’ll get a fast cutting experience through relatively thick metals. If you compare the cutting speed of plasma cutter with any cutting tools, you’ll find a plasma cutter as a winner. A plasma cutter gets the jobs done in one-fourth the time of any other cutting tools. This tool doesn’t require to be preheated before cutting. Thus, it saves the cutting time. However, faster speed can be obtained on thinner metals with plasma, with minimal or no metal distortion.

Precision cut

Precision or accurate cutting is one of the advantages of a plasma cutter. The tool utilizes an innovative process in which a cone shape high-temperature steam makes your cutting result more precise. A plasma cutter cuts precisely with minimal slag and provides cutting with a narrower kerf. Making many different shapes or angles with sheet metal by plasma cutter is a breeze.

Versatility

If you expect versatility in your cutting tool, what can be a better option than a plasma cutter?

Yes, it is the tool that offers benefits for cutting thinner non-ferrous and ferrous metals. The device is able to cut virtually all types of metal including copper, titanium, cobalt, carbon steel, cast iron, nickel alloys, stainless steel and so on. Plasma cutter provides the facility to shape metal- channels, tubes or angles. You can easily cut large volumes of thin sheet metal with the fastest cutting speed. The ability to cut a wide range of thickness and types of metal makes a plasma cutter a perfect solution for industries that need to cut various thickness and types of metal.

Lower Cost

Comparatively the plasma cutter costs less. If you expect “return” on your investment, choose a plasma cutter as your cutting tool. What Oxy-fuel costs to cut 12mm thick steel, a plasma cutter costs half the amount of money. If you compare the energy used by the other cutting system, you’ll find that a plasma cutter uses less energy. Ultimately it saves your utility bills. On the other hand, most of the plasma cutters are made for use year after year. So, you may not need to replace it very often.

Ease Of Use

Most of the metal cutters need some training and practice to use efficiently. But plasma cutters are easy to use and don’t need much training to handle. If these tools are used in the industry, it will save training cost of employees. The plasma cutter torches are usually user- friendly and easy to operate. Even a new user can make almost perfect cutting on the first try.

Cons of CNC Plasma Cutter:

• Hardened Edges: the plasma cutter will create a warmth affected region and harden the edges of the material being cut.

• Dross: Many plasma cut parts will contain some dross that wants to be cleaned from the part but this has been minimized with today's elevated performance plasma cutting systems.

• Cost: CNC plasma cutters can price more, but faster cutting speed and high cut quality permit for earlier making with less labor intensive secondary operations. The long term efficiency and accurateness are elements which figure into the overall price of a plasma cutter, not simply the price.