Views: 10 Author: Site Editor Publish Time: 2022-04-15 Origin: Site

Stainless steel is easier to obtain deep penetration narrow welds due to its low thermal conductivity, high energy absorption rate and melting efficiency. So in general, jewelry laser welder for sale stainless steel is easier to obtain high-quality joints.

The device’s two most important functions, the welding frequency and the impulse length can be controlled using two switches. A higher setting for the impulse length enables a greater penetration depth whenever necessary, which leads to a greater strength of the welding points in addition, the welding points can be structured with greater fineness. A high performance adapter shortens the welding frequencies, and work on the jewelry can be carried out faster as a result. In this, the thermal effects of the light arc on the work piece remain very low. The work piece can therefore be held in the hand without any problems; also, welding close to a gemstone or on jewelry that has already been polished does not have any major repercussions.

The unique properties of laser welding give it a significant advantage over other forms of welding that can be exploited in several ways:

Precision parts: Lasers are excellent for welding fine and delicate metal components and generating minimal internal stresses due to the minimal heat input.

Medical devices: Non-contact welding and no welding splatter ensures hygiene when welding medical devices.

Solenoids and machined items: Lasers are ideal for joining machined components such as solenoids, and create minimal distortion due to the low heat input.

Aesthetics: Laser welding finishes are excellent.

Limited access: The non-contact laser beam permits welding in otherwise inaccessible areas.

Jewelry welding and high value items: The precise controllability and negligible heating effects make it a good choice for welding high value, high precision parts including precious metals.

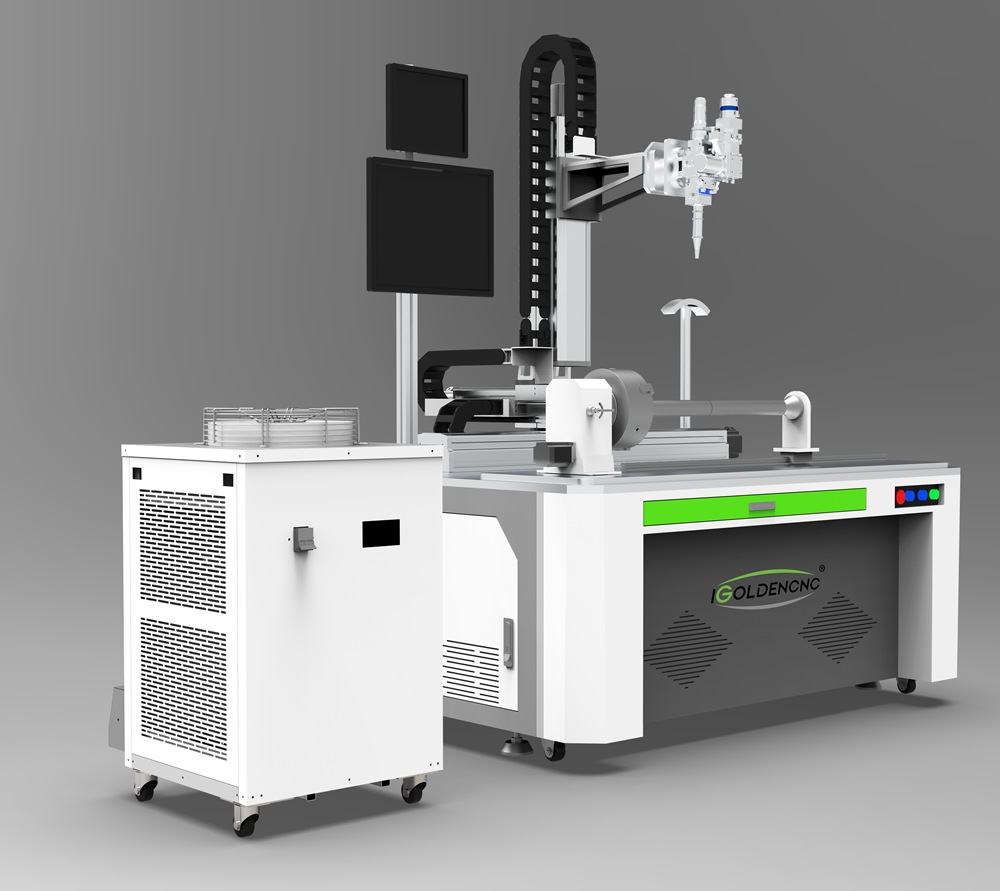

Gold jewellery welding machine parts :

1. Nozzle

Customer can change the corresponding nozzle according to different welding processes, and can twist the copper nozzle to adjust the focal length, and the adjustable range of the focal position is ±15mm.

2. Wire Feeding Device:

Lightweight bend wire feeding structure, wire feeding Angle position can be adjusted conveniently.

3. Trachea Interface

Protective gas inlet.

4. Lead Signal Line

It is communicated with copper nozzles. When welding, contact with iron plate ground wire will produce a circuit, which plays a role of safety protection.

5. Protective Lens Mounting Port

The protective lens is equipped with water-cooled structure, so the protective lens can last longer. It is recommended to wipe the dust of protective lens once a day with alcohol-free cotton swab.

6. Circulating Water Channel

Cold water circulating structure is used to cool the reflector and gun body.

7.LCD

Used to show whether the parameters and signal state set by the system are normal.

8. Gun Handle

Aluminum a process, light and light grip comfortable.

After changing the structure of head and the position of the trigger button, it can be used for both left and right hands.

9. QBH Protective Cover

Connect with the laser end, pay attention to cleaning during installation to avoid dust entering the gun body.