Views: 4 Author: Site Editor Publish Time: 2021-10-12 Origin: Site

The function and function of the Metal Laser Cutting Machine are very good, but this kind of laser cutter metal will have certain difficulties when cutting. We must pay attention to this when using it.

The difficulty of cutting a thick plate with a Metal Laser Cutting Machine - the slit is too narrow, resulting in increased heat loss. The reduction in laser cutting rate promotes thermal damage in the laser cutting area. The key way of thermal damage is heat conduction. The thicker the thickness, the greater the thermal damage and the lower the laser cutting rate. Although the laser penetrates the slab and a large amount of slag adheres to the bottom, the material removal at the bottom of the cut becomes inconsistent. The slag formation is due to the low average cutting temperature at the bottom of the slit, and the low temperature is also due to the large energy loss. In this case, the quality of the cut is usually not high - the fiber laser spot diameter is small and the focal depth is limited. Although the fiber laser can maintain a high laser power density at the cutting depth when cutting the metal plate, since the beam diameter is small, the cutting slit is thin, which is disadvantageous for cutting the slag. This puts higher requirements on the mode, beam dispersion, collimation, shaping and range of the fiber laser, and also brings more difficulties to the process quality of the fiber laser cutting metal plate - the auxiliary vapor quality and the standard pressure. Efficacy and harm. Taking oxygen as an example, oxygen laser plays a very important role in cutting thick plates in carbon steel. The laser beam is incident on the surface of the workpiece to form small holes. As the laser beam moves in the direction of the cut, there is an oxidizing melt around the orifice and the slit. The purity and pressure of oxygen have a major impact on laser cutting. Oxygen containing many impurities and improper gas pressure does not provide sufficient energy to form a high flow melt at the bottom of the slit, thereby reducing the quality of the cut and the cutting speed. By measuring the mass and pressure of the auxiliary gas at different slit locations, it is found that the narrower the slit, the worse the effect of the auxiliary gas, and the more difficult the cutting quality is to maintain, thus ensuring proper slit width, auxiliary gas quality and air pressure control. The effect on the quality of the cut is very heavy - the difference in geometry looks like a reduction in the quality of the inflection laser cut. When the fiber laser cuts the thick steel plate, the inclination angle of the melting front is more and more prominent, which will reduce the absorption coefficient of the raw material to the laser, thereby ensuring the laser cutting quality according to the laser cutting output power and the laser cutting rate.

Laser cutting machine steel is to focus the laser light emitted from the laser into a high power density laser beam through the optical path system. The laser beam irradiates the surface of the workpiece to make the workpiece reach the melting point or boiling point, and the high-pressure gas coaxial with the beam blows away the molten or vaporized metal. As the relative position of the beam and the workpiece moves, the material will eventually form a slit, so as to achieve the purpose of cutting.

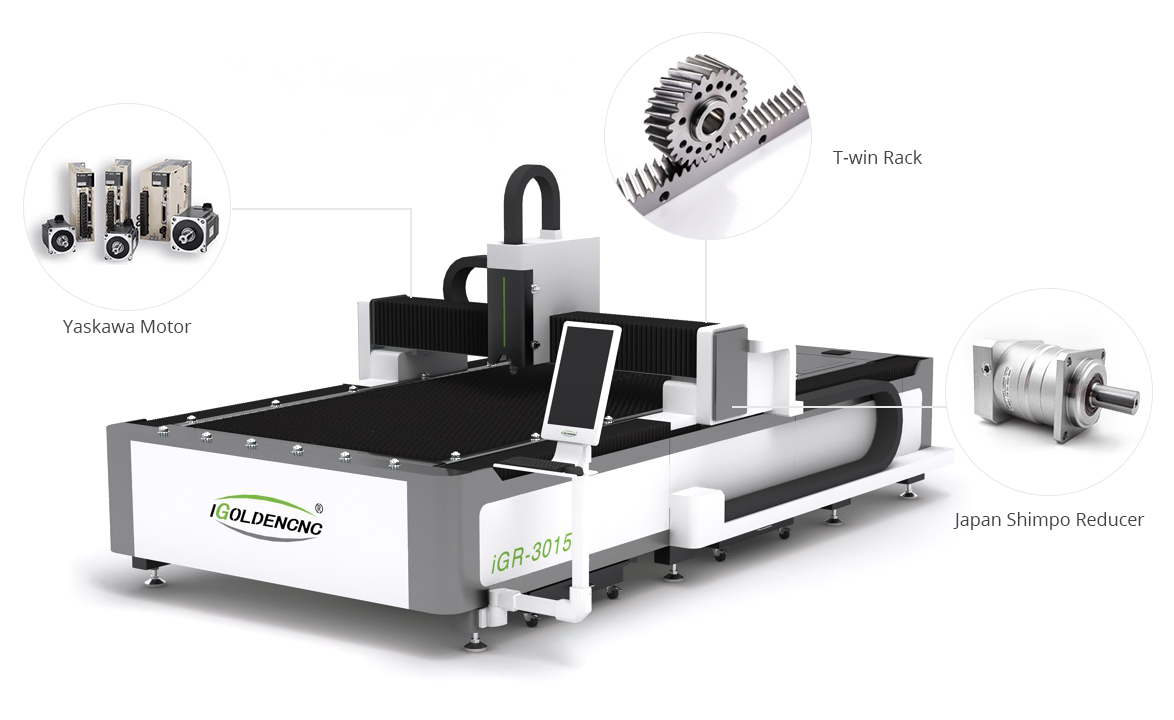

HIGH-PRECISION TRANSMISSION SYSTEM

Adaptability of Metal Laser Cutting Machine:

(1) High precision and fast speed, mainly for fast and precise cutting of metal plates below

4mm.

The processing advantages of Metal Laser Cutting Machine are as follows:

(1) High precision, fast speed, narrow cutting seam, minimum heat-affected zone, smooth

cutting surface without burrs;

(2) The stainless steel laser cutting machine price head does not touch the surface of the

material and will not scratch the workpiece;

(3) The slit is the narrowest, the heat-affected zone is the smallest, the local deformation

of the workpiece is small, and there is no mechanical deformation;

(4) Good processing flexibility, can process any graphics, and can also cut pipes and

other profiles;

(5) It can cut any hardness materials such as steel plate, stainless steel, aluminum alloy

plate, cemented carbide, etc. without deformation.