Views: 40 Author: Site Editor Publish Time: 2021-10-07 Origin: Site

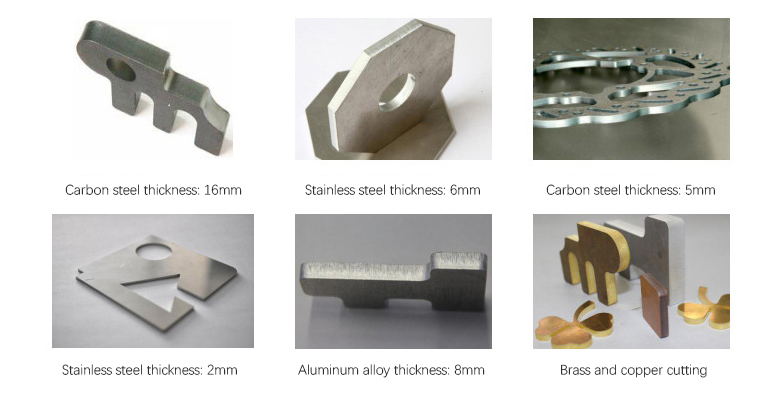

Metal Laser Cutting Machine Is A Kind Of CNC Laser Metal Cutting System With High Quality, High Speed, High Precision And High Efficiency. It Is Suitable For All Kinds Of Metal Cutting Which Will Be Your Good Metal Working Partner. It Is Equipped With Different Powers (from 1000w To 15000w) For Cutting Metal Sheets/plates And Metal Tubes/pipes Of Stainless Steel, Carbon Steel, Electrical Steel, Galvanized Steel, Aluminum Zinc Plate, Aluminum, Aluminum Alloy, Titanium Alloy, Copper, Brass, Iron And Other Metal Materials With Different Thicknesses. Fiber Laser Cutter Is Also Known As Fiber Laser Metal Cutting Machine, Fiber Laser Cutting Machine, Fiber Laser Cutting System, Fiber Laser Cutting Equipment.

1. First of all, the dust on the machine table of the metal laser cutting machine does not matter. You can clean it any way you want. However, it is not recommended to clean the dust inside the machine. Improper removal can easily scratch the laser head. In severe cases, it will cause the laser to read and write data. Can not be accurately positioned.

2. Secondly, as long as the dust does not fall on the surface of the laser head, it will not affect the use. The safest way is to turn the metal laser cutting machine upside down (laser head down) and use a blower (a tool for cleaning digital SLR CCDs, which is very cheap). ) Blow off the dust.

3. In addition, pay special attention to the replacement of water and the cleaning of the water tank (it is recommended to clean the water tank and replace the circulating water once a week).

So, how to deal with the smoke generated by the laser cutting machine, what is the best and most effective way to deal with the smoke?

At present, the commonly used laser cutting dust removal methods are mainly divided into two types: dry and wet.

1. Dry processing method (dry cutting)

Dry cutting is to add a set of smoke and dust collection devices to the cutting work platform, and the collected smoke and dust are directly transported to the smoke and dust filtration and purification equipment, and the unified filtering treatment will be discharged after reaching the standard. The smoke and dust produced by cutting are basically formed under the cut of the workpiece, so the suction type negative pressure cutting platform has become the most common smoke and dust collection device at present.

In order to save equipment investment and improve the ventilation efficiency, that is, to achieve a higher collection of smoke and dust with a smaller suction volume-only the area that is in the cutting process is vacuumed, so the cutting platform will be moved along the main guide rail of the cutting machine. Divided into (uniform) airtight small areas with air outlets on the side. The working form of the suction port is divided into a side suction mobile suction port and a valve suction port on the side wall of the vacuum chamber. Among them, the former is widely used because of its simple structure, reliable work and better dust removal effect.

2. Wet processing method (wet cutting)

In fact, it is to make a waterbed cutting platform, place the workpiece in the water or on the water surface, and then complete the cutting operation underwater or close to the water surface, and use water to capture the smoke and dust generated during the cutting process, so as to achieve the purpose of purifying the environment.

Scope of Application

Beam made of cast aluminum

Aluminum monolithic cast beam, light weight, high strength, no deformation Light crossbeams, which are molded and framed using integral steel mold and die-casting technology, give equipment a high operation speed, improving processing efficiency and quality.